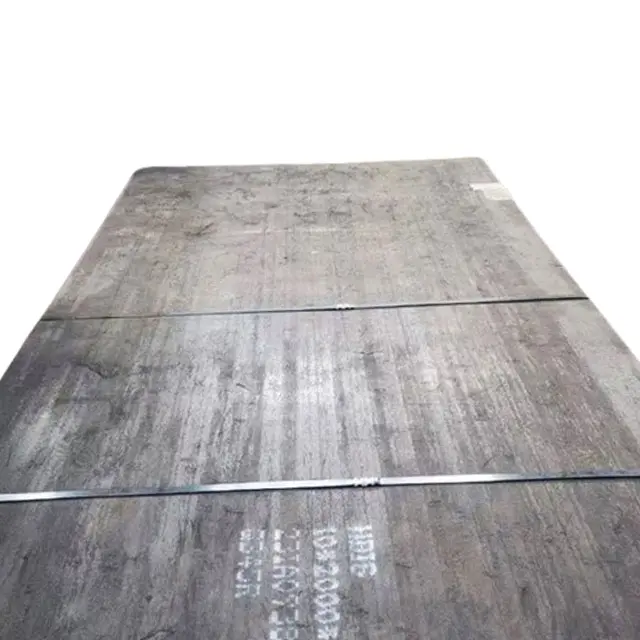

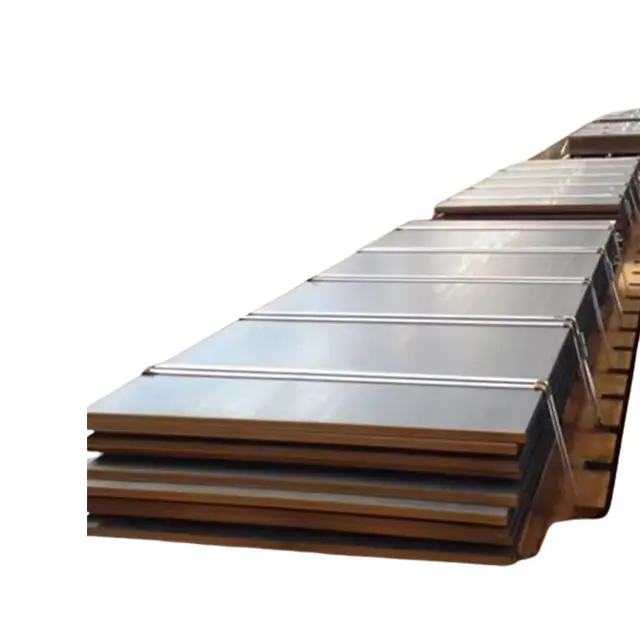

Zhixin compound super wear-resistant steel plate

Features of Zhixin Wear-resistant Plate

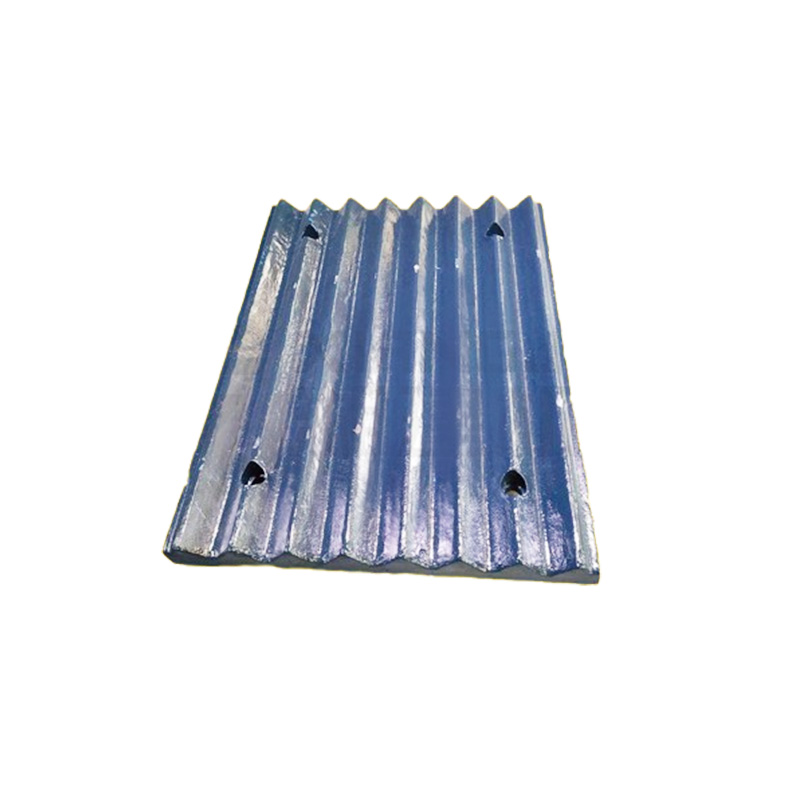

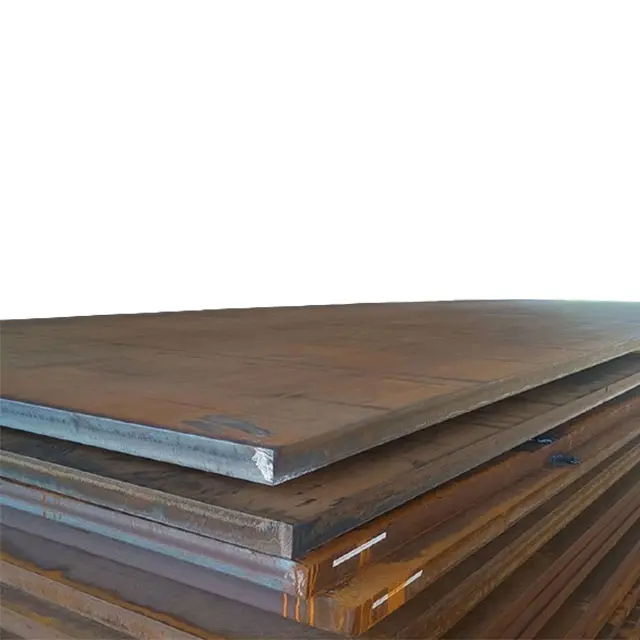

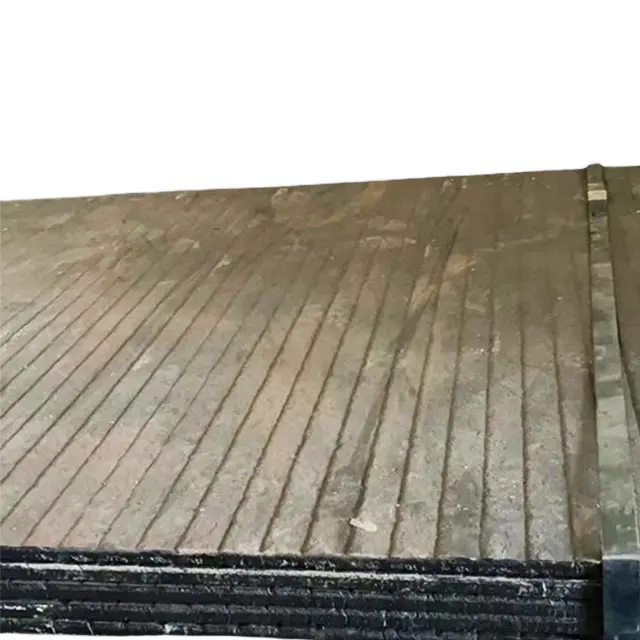

1. The hardness of the surfacing layer is extremely high and there are fewer cracks; the base plate is reliable, does not crack, and has good toughness. The wear-resistant layer does not fall off, and the bonding strength between the wear-resistant layer and the base plate is 345MPa.

2. Multi-layer surfacing can be performed to increase the hardness of the surfacing layer;

3. It can withstand high temperature use;

4. The cost is much higher than the composite wear-resistant plate on the market, and the service life is greatly improved.

5. The highest hard alloy particle is HV1750

● 40-45% primary carbide M7C3 (hypereutectic)● 15-20% secondary carbide M3C (eutectic and hypereutectic)

● Conditions for the formation of hard particles:

● Sufficient carbon and chromium content is required.

● Composition determines the structure, and the structure determines the quality.

Actual use cases:

After 4 months of use, the ceramic fell off and the turtle glue was worn through. The composite steel layer was almost not worn out.

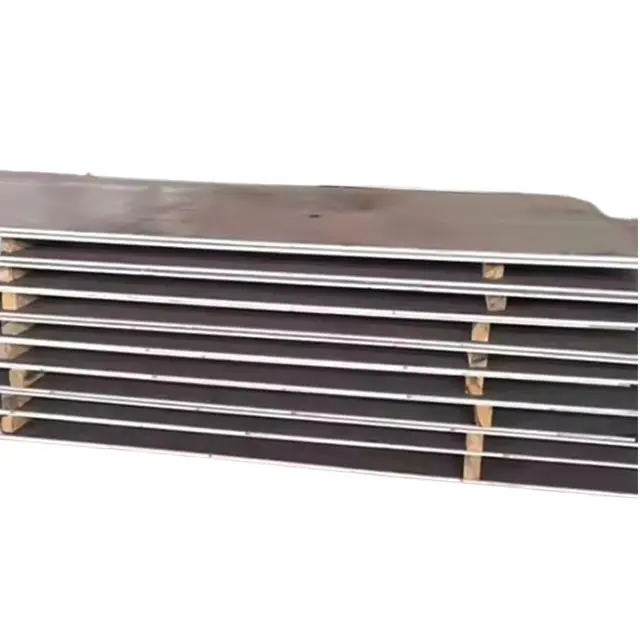

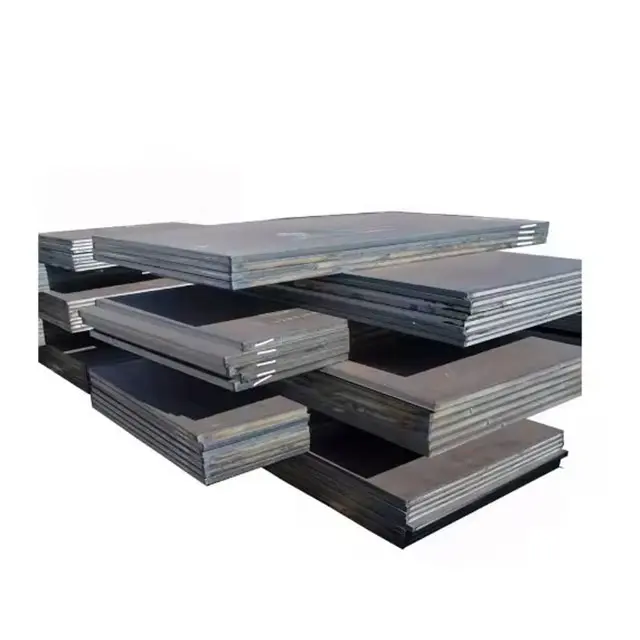

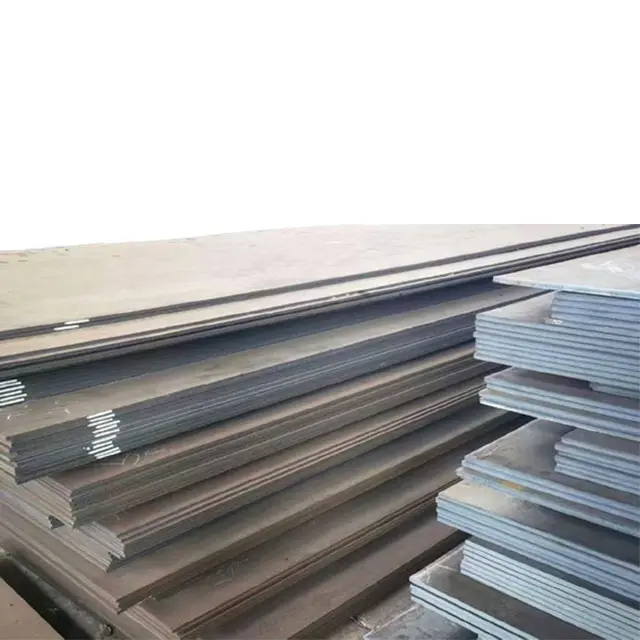

Various product specifications to meet different needs

The company provides a variety of thickness specifications, including **4+4mm, 6+4mm, 6+6mm, 8+8mm, 10+10mm**, etc., which can be customized according to customer needs to ensure that they are suitable for wear-resistant protection needs under different working conditions.

Widely used, excellent performance

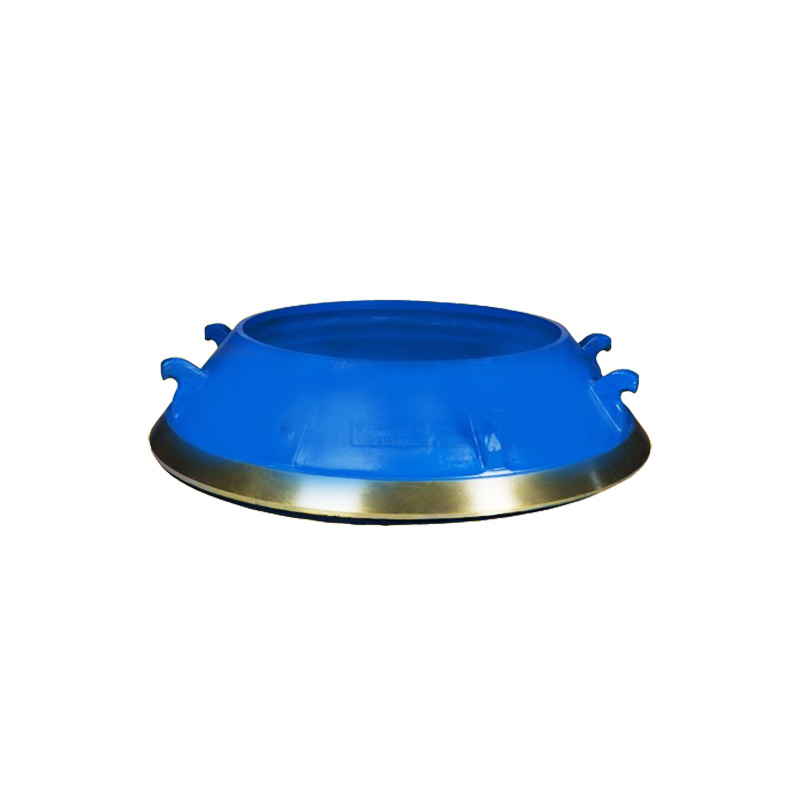

Our wear-resistant steel plates are widely used in:

- Cement production equipment (such as powder selection machine lining, chute, mill lining)

- Mining equipment (crusher, vibrating screen, conveyor lining)

- Tunnel engineering (shield machine cutter head, slag conveying system)

- Coal industry (hopper, chute, pipeline lining)

- Steel (silo lining, inclined sliding surface, screen, blower cover, material car, barrel, pipeline, dump truck, hopper)

This product has the characteristics of high hardness, impact resistance, corrosion resistance, easy welding, etc., which greatly extends the service life of equipment and reduces maintenance costs. It is an ideal choice in the field of industrial wear resistance. It has received good feedback from customers.

Chengdu Zhixin Refractory takes technological innovation as its core and is committed to providing customers with cost-effective, high-durability** wear-resistant solutions to help enterprises improve production efficiency and reduce operating costs!

This product has the characteristics of high hardness, impact resistance, corrosion resistance, easy welding, etc., which greatly extends the service life of equipment and reduces maintenance costs. It is an ideal choice in the field of industrial wear resistance. It has received good feedback from customers.

Chengdu Zhixin Refractory takes technological innovation as its core and is committed to providing customers with cost-effective, high-durability** wear-resistant solutions to help enterprises improve production efficiency and reduce operating costs!