Products

Zhixin compound super wear-...

Cone crusher is mainly composed of moving cone and fixed cone. The motor drives the eccentric sleeve to rotate through the pulley or coupling, and then makes the moving cone do pendulum motion. When the ore enters the crushing chamber from the feed port, the distance between the moving cone and the fixed cone changes continuously. When approaching, the ore is crushed by extrusion, bending and impact; when the moving cone leaves, the crushed ore moves downward under the action of gravity and is continuously crushed until the particle size meets the requirements and is discharged from the discharge port.

In the quarry application o...

Cone crusher is mainly composed of moving cone and fixed cone. The motor drives the eccentric sleeve to rotate through the pulley or coupling, and then makes the moving cone do pendulum motion. When the ore enters the crushing chamber from the feed port, the distance between the moving cone and the fixed cone changes continuously. When approaching, the ore is crushed by extrusion, bending and impact; when the moving cone leaves, the crushed ore moves downward under the action of gravity and is continuously crushed until the particle size meets the requirements and is discharged from the discharge port.

High manganese steel cone c...

High wear resistance: Under large impact or contact stress, the surface layer is rapidly hardened, and the hardening index is 5-7 times higher than other materials, which greatly improves wear resistance.

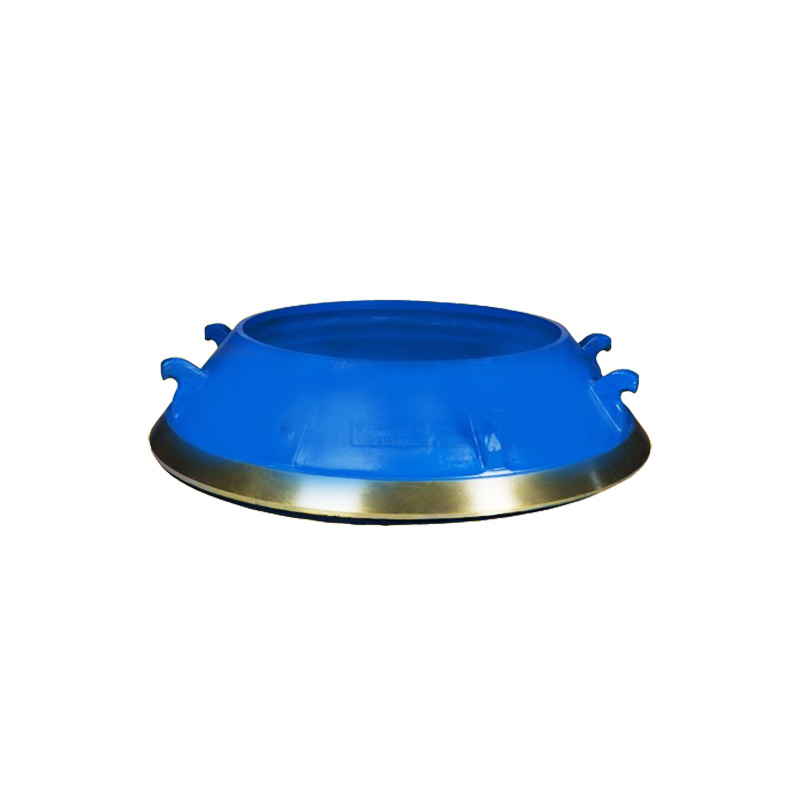

Cone crusher mantle and con...

The cone crushing wall is the key component in the cone crusher that directly contacts the material.

Bowl liner rock cone crushe...

The mantle concave is connected by casting zinc alloy. Its firmness should be checked after the cone crusher has been running for a period of time. The connection between the mortar wall and the adjustment ring is fixed by U-shaped fixing screws. Zinc alloy is cast between the mortar wall and the adjustment ring to make them tightly combined.

China Manufacturer cone cru...

Cone crusher: Cone crusher is the best choice for aggregate production and mining, featuring its unique combination of crusher speed, eccentricity and cavity type.

Cone crusher alloy manganes...

During the working process of cone crusher, the motor drives the eccentric sleeve to rotate through the transmission device, and the moving cone rotates and swings under the force of the eccentric sleeve. The section where the moving cone is close to the static cone becomes the crushing chamber, and the material is crushed by multiple squeezing and impact of the moving cone and the static cone. When the moving cone leaves this section, the material that has been crushed to the required particle size falls under its own gravity and is discharged from the bottom of the cone. The material to be crushed is loaded from the feed port of the cone crusher.

Factory Direct Sale New Min...

As the core equipment of mining, building materials and other industries, the operating status of jaw crusher is directly related to production efficiency and economic benefits. However, due to the harsh environment of crushing operation and long-term use, the jaw crusher is subjected to high-intensity impact and friction, and its wearing parts are prone to wear and breakage, which will not only affect the performance and efficiency of the equipment, but also may cause the shutdown of the production line. Therefore, it is necessary to check and replace them regularly in time to ensure the normal operation and production efficiency of the equipment. 1. Types and replacement cycles of jaw crusher wearing parts.

Good Selling Coal Mining Mi...

Zhixin is a professional manufacturer of crusher parts. Servicing the mining and construction industries for years, we have built up a scientific system of production, sales and services. We are offering products over 20 countries and enjoy good reputation among our customers for high-quality products, integrity and responsibility.Our products range from cone crushers and jaw crushers to bronze casting parts, high-manganese steel casting parts and steel parts, which meet OEM standard and produced basing on the original drawings. High-efficient and high-precision processing equipment is widely used in our production line. Our qualified engineers, skilful workers and office staff with rich exporting experience ensure us to present high-quality products to our customers.

Our goal is to provide overall cost-saving products and improve the productivity of equipment.

Factory Casting Ore Mining ...

Jaw crusher is a common coarse crushing equipment in sand and gravel production lines. It is named because it simulates the movement of the two jaws of animals to complete the material crushing operation. The output particle size is one of the important indicators of its production quality, and the size of the discharge port determines the particle size of the ore after crushing.

Factory Wholesale Energy & ...

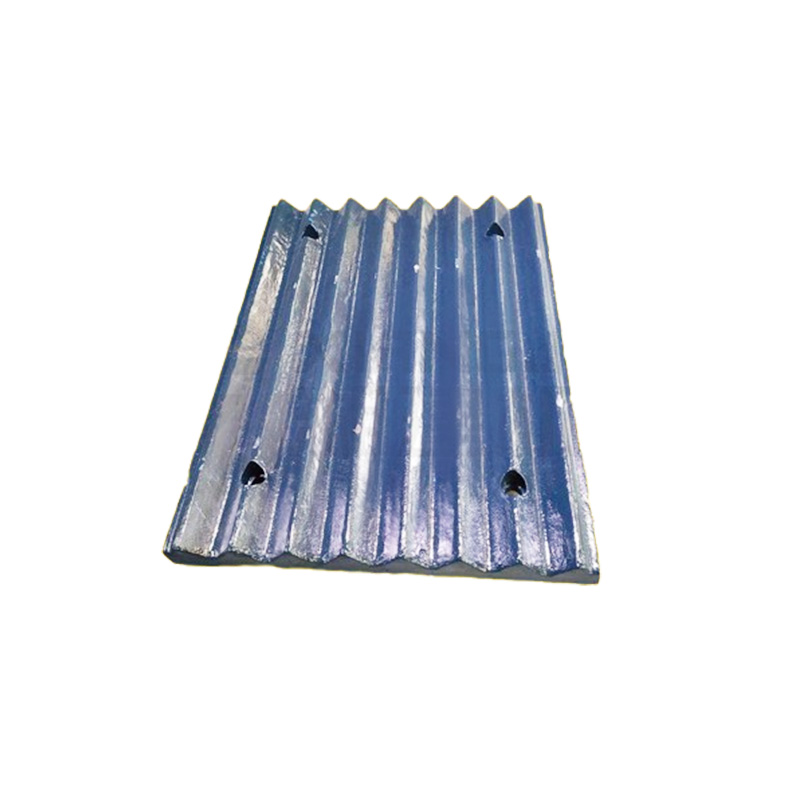

The jaw plate of jaw crusher is divided into fixed jaw plate and movable jaw plate, generally both of them are high-manganese steel castings. When working, the movable jaw is attached to the movable jaw plate to make a compound swing motion, forming an angle with the fixed jaw plate to squeeze the stone. Therefore, the jaw plate of jaw crusher is easy to wear and needs to be replaced within a certain period of time. In order to extend its service life, its shape is generally designed to be symmetrical up and down, that is, it can be turned around when one end is worn. The movable jaw plate and the fixed jaw plate are the main contact surfaces when crushing stones. The movable jaw plate is installed on the movable jaw to protect the movable jaw.

Factory Price Casting High ...

The jaw plate is one of the core components of the jaw crusher, including the movable jaw plate and the fixed jaw plate. When working, the jaw peaks of the movable jaw and the fixed jaw should face the jaw valleys. In this way, in addition to the squeezing effect on the material, there is also a bending effect during crushing, making it easier to crush the material.

The material of the jaw plate is usually manganese steel containing more than 13% manganese, and ZGMn13 and ZGMn18 are commonly used. Our high-performance jaw plates are added with specially developed alloys to further improve the wear resistance of the jaw plates and extend their service life.