Working principle and practical application of jaw crusher

2025-01-15

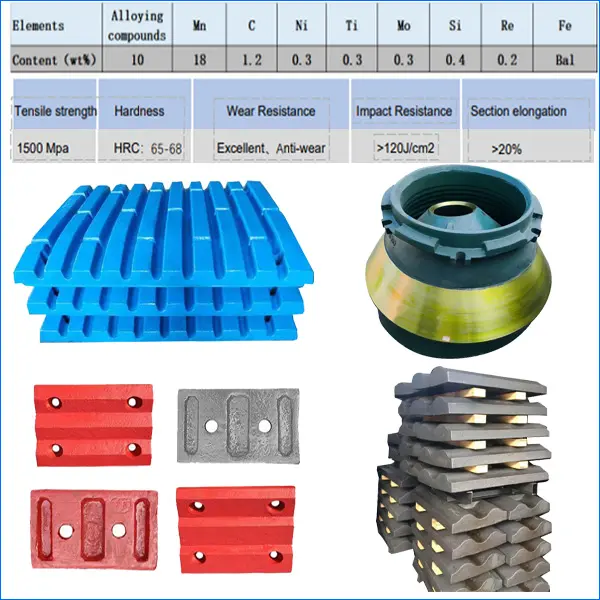

In actual use, Jaw Crushers have become indispensable crushing equipment in many industries due to their advantages such as high efficiency, energy saving and strong adaptability. The working principle of jaw crushers is relatively simple and effective. It mainly consists of the following parts: movable jaw plate, fixed jaw plate, eccentric shaft, large pulley, flywheel, toggle plate, gap adjustment screw, reset spring, etc.

The jaw crusher consists of two jaw plates, the movable jaw and the fixed jaw. The fixed jaw plate is stationary, while the movable jaw plate can swing within a certain range. The working power of the jaw crusher comes from the motor, which drives the eccentric shaft to rotate through the transmission device. The eccentric shaft is connected to the movable jaw, allowing the movable jaw to swing periodically. The space between the movable jaw and the fixed jaw constitutes the crushing chamber, and the material is placed in the crushing chamber. When the motor is started, the eccentric shaft drives the movable jaw to reciprocate. The movable jaw swings around the fixed jaw plate, and the material is crushed under the extrusion of the movable jaw and the fixed jaw. When the material is crushed to the required particle size, it will be discharged from the bottom of the crushing chamber under the action of its own gravity. The toggle plate acts as a safety device. When there are unbreakable objects in the crushing chamber, the toggle plate will break to protect the equipment. The gap adjustment screw is used to adjust the gap between the movable jaw and the fixed jaw to control the particle size of the discharged material. In the design of some jaw crushers, the return spring can help the movable jaw return to its original position quickly to continue the next crushing cycle.

Jaw crusher is a widely used crushing equipment with the characteristics of simple structure, reliable operation, easy maintenance, strong adaptability and low cost. The following are some key points of jaw crusher in practical application:

1. Crushing capacity: jaw crusher can handle minerals and rocks with compressive strength not higher than 320 MPa, the maximum feed size can reach 1020mm, the minimum discharge size can reach 10mm, and the production capacity can reach up to 800 tons per hour.

2. Application field: jaw crusher is widely used in many industries such as mining, metallurgy, building materials, highway, railway, water conservancy and chemical industry. It is often used in conjunction with Cone Crusher, impact crusher, sand making machine, etc. to form a sand and gravel production line.

3. Crushing process: jaw crusher is usually used in the first process of the crushing process, processing various minerals to medium particle size at one time.

4. Structural design: the new external jaw crusher changes the design of the traditional jaw crusher, separates the movable jaw from the connecting rod, improves the kinematic mechanical properties, makes the crushing chamber inclination larger and the cavity deeper, which is conducive to feeding and discharging, and achieves a large crushing ratio.

5. Performance advantages: The new jaw crusher has the characteristics of low profile, large crushing ratio, reasonable moving jaw movement trajectory, extended liner life and high production capacity.

6. Actual application effect: In the actual application case, the external moving jaw crusher has an hourly processing capacity of about 330 tons when the discharge particle size is 200mm, and the wear rate of equipment parts is low.