Working principle and practical application of cone crusher

2025-01-15

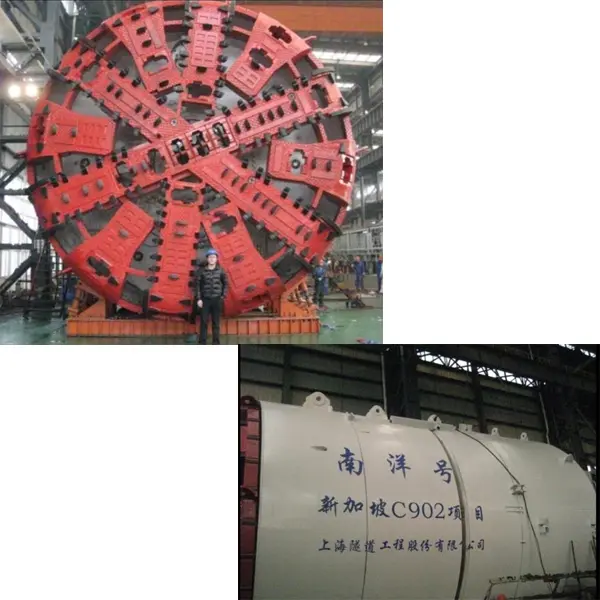

Cone Crusher is a kind of crushing equipment widely used in mining, construction, chemical industry and other industries. Its working principle is mainly based on lamination crushing.

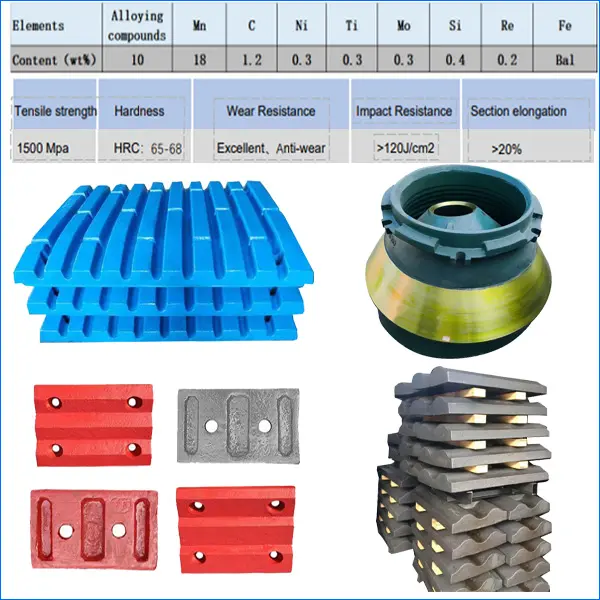

Cone crusher mainly consists of two parts: Cone Mantle and concave. Moving cone is the main working part of cone crusher, which is driven to rotate by motor. Fixed cone is a fixed part, which works with moving cone. When the material enters the crushing chamber, the rotation of moving cone drives the material to be crushed between fixed cone and moving cone. The material is first impacted by moving cone, and then squeezed between moving cone and fixed cone, and crushed by lamination. By adjusting the gap between moving cone and fixed cone, the particle size of the discharged material can be controlled. The smaller the gap, the finer the particle size of the crushed material. The crushed material is discharged through the discharge port. The size of the discharge port can be adjusted as needed to meet different particle size requirements. Modern cone crushers are usually equipped with hydraulic systems for adjusting the gap of crushing chamber, and automatic clearing of blockages when encountering unbreakable objects to protect the equipment from damage. The cone crusher also has a good lubrication system to ensure that the friction between the moving cone and the fixed cone is minimized and the equipment life is extended.

Cone crushers mainly rely on the relative movement of the inner cone and the outer cone to crush the material into small pieces through extrusion. The following are some characteristics and application scenarios of cone crushers in actual use:

1. Technical characteristics: Hydraulic cone crushers have the characteristics of high production capacity, small product particle size, stable operation and reliable performance.

2. Multi-cylinder structure: Multi-cylinder hydraulic cone crushers adopt large eccentricity, which can achieve a large crushing ratio and have the advantages of a high proportion of finished products at one time.

3. Application field: Multi-cylinder hydraulic cone crushers are widely used in construction engineering, metallurgical industry, sand and gravel industry, highway construction, mine and airport construction, nuclear power construction and cement industry.

4. Factors affecting output: The output of cone crushers is related to factors such as feeding method, feeding block size, discharge block size, physical and mechanical properties of ore, temperature, etc.

5. Maintenance and replacement: The maintenance of cone crushers includes regular inspection of the tightness of the mortar wall and the cone crushing wall, and timely replacement of worn gears, bushings and other parts.

6. Hydraulic system: The hydraulic cone crusher is equipped with a hydraulic system to adjust the size of the discharge port, ensure the safe operation of the equipment, and automatically retract the cone when there is a foreign object in the crushing chamber.

7. Market demand: With the expansion of domestic demand and infrastructure construction in the country, the demand for sand and gravel and related crushing machinery has increased dramatically, and the market prospects for cone crushers are broad. The actual application of cone crushers is very extensive, and their high efficiency, stability and reliability make them an indispensable equipment in many industries.