Application fields of wear-resistant steel plates

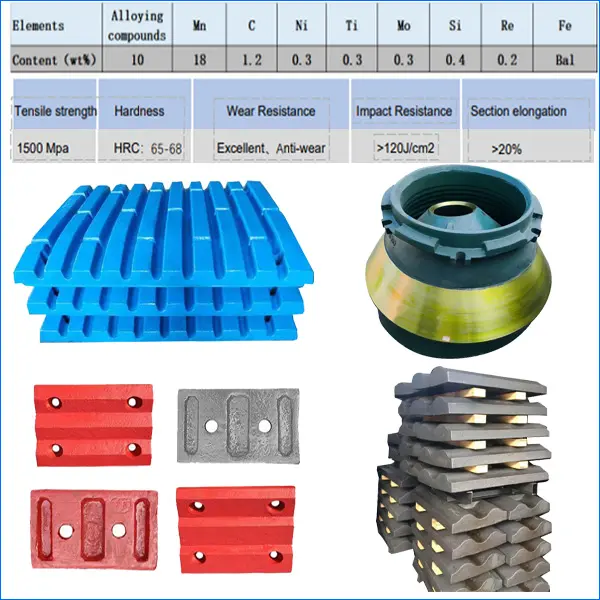

Wear resistant steel plates are mainly made of low-carbon steel or low-alloy steel with good toughness and plasticity, and the surface is composited with a layer of alloy wear-resistant layer with high hardness and excellent wear resistance by surfacing welding. This composite layer not only provides higher wear resistance, but also the substrate can provide comprehensive properties such as strength, toughness and plasticity to reduce external forces.

Wear-resistant steel plates are widely used in the following fields and equipment due to their high hardness, impact resistance and wear resistance:

- Engineering machinery

Application equipment: excavators, loaders, bulldozers, buckets, excavator teeth, crusher liners, etc.

Use: protect easily worn parts (such as shovel blades, bucket walls) and extend equipment life.

- Mining

Application equipment: mining truck compartments, vibrating screen plates, conveyor liners, crusher rotors, chutes, etc.

Use: resist high-intensity wear and impact of ore and sand and gravel.

- Building materials and cement industry

Application equipment: ball mill lining, roller press roller surface, powder selector blade, silo lining, etc.

Purpose: reduce the wear of cement raw materials and clinker on equipment.

- Electricity and energy

Application equipment: coal mill blades, coal conveying pipelines, fan blades, boiler linings, etc.

Purpose: resist the erosion and wear of coal and ash.

- Metallurgical steel industry

Application equipment: blast furnace hopper, sintering machine lining, rolling mill guide plate, continuous casting machine roller, etc. Steel: silo lining, inclined sliding surface, screen, blower cover, material car, barrel, pipeline, dump truck, hopper, etc.

Purpose: resistant to high temperature wear and metal particle impact.

- Agricultural machinery

Application equipment: harvester blades, plowshares, feed mixer linings, etc.

Purpose: reduce the wear of soil and crop straw.

- Material conveying and handling

Application equipment: screw conveyor, discharge hopper, garbage treatment equipment, etc.

Purpose: protect equipment from long-term friction of particulate matter or waste.

- Chemical and environmental protection

Application equipment: dust collector housing, sludge conveying equipment, chemical reactor lining, etc.

Purpose: dual role of corrosion resistance and wear resistance.

- Transportation

Application equipment: dump truck compartment, container floor, railway truck lining, etc.

Purpose: withstand the impact and wear of heavy-loaded goods such as sand, gravel, and ore.

- Other special fields

Military equipment: armored vehicle protective plate.

Shipbuilding: cargo hold lining, dredging equipment.

The wear-resistant steel plates produced by Zhixin Refractory Technology are widely used in many of the above fields and have received good feedback from customers over the years.

The tensile strength test of the wear-resistant layer and substrate (A36) of Zhixin wear-resistant composite lining has a maximum tensile strength of 345MPa.

Practical application cases:

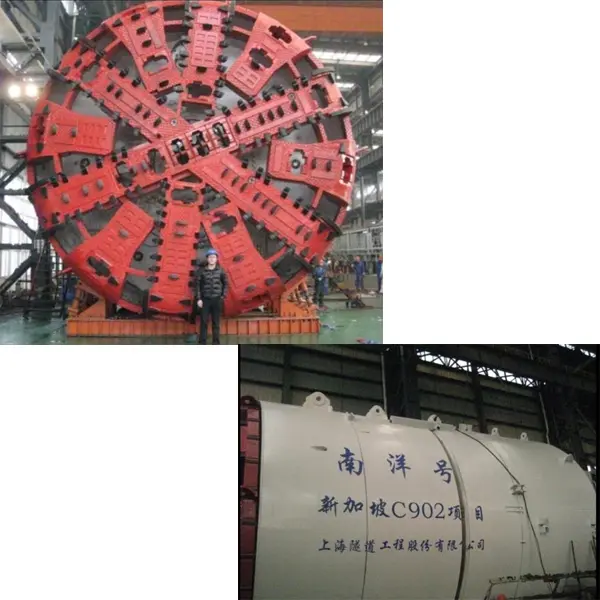

- The wear-resistant plates provided by our company for the Nanyang TBM of Singapore C902 project have been fully recognized by the project party.

- The company produces a large number of wear-resistant steel plates for large coal mining companies, which are mainly used in the grinding roller head linings, guide device support plates, impeller devices, scraper devices, grinding bowl linings, etc. of customers' coal mills.

If your equipment needs wear-resistant steel plates, you are welcome to consult and negotiate at any time. We can provide you with a whole wear-resistant steel plate, or we can customize it according to your size requirements.