0102030405

The wear parts industry is moving towards sustainability

2025-01-15

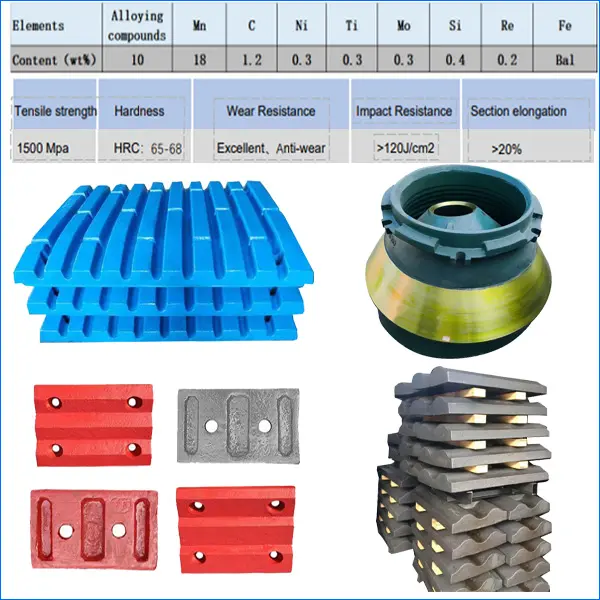

The development of the wear-resistant parts industry has gone through the process from ancient stone tools and bone tools to bronze and iron in the metal age, and then to high manganese steel and high chromium cast iron in the industrial revolution, as well as new materials in the modern science and technology era such as ceramic materials, polymer composite materials, coating technology, etc. These advances have not only improved the wear resistance of materials, but also promoted the innovation and development of the industry. In recent years, with the enhancement of environmental awareness, the wear-resistant materials industry has begun to focus on the research and development of environmentally friendly wear-resistant materials, and promoting the recycling of resources and reducing pollution to the environment has become an important direction for the development of the industry.

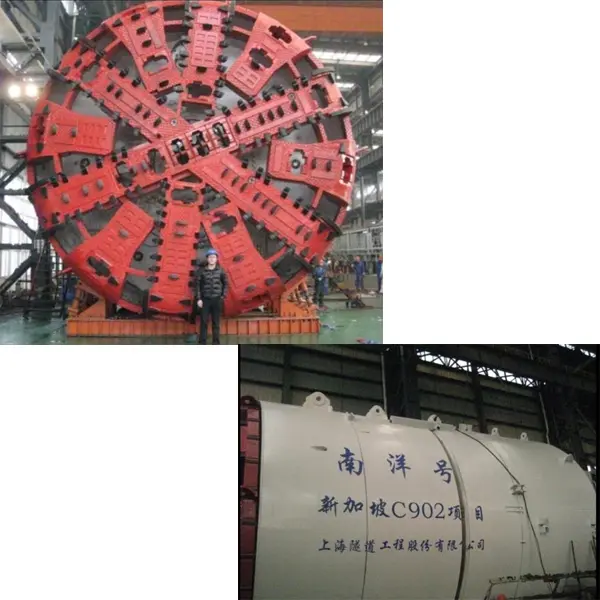

The industrial chain of the wear-resistant and heat-resistant casting industry covers the complete process from raw material supply, casting production to the final application market. Raw material supply includes metal raw materials such as scrap steel and pig iron, as well as special materials such as rare earth and alloy. In the casting production process, enterprises ensure the quality and performance of castings through advanced production equipment, process technology and strict quality control system. Wear-resistant and heat-resistant castings are widely used in metallurgy, electric power, building materials, mining, machinery and other fields, such as rolling mill roller rings, blast furnace tuyere, mining crusher hammer, excavator bucket teeth, etc. These castings can maintain stable performance in extreme working environments, extend the service life of equipment and improve production efficiency.

Current situation of wear-resistant materials industry

Market scale expansion: With the development of industrial production and the increase in demand, the market scale of wear-resistant materials has gradually expanded. Wear-resistant materials have a wide range of applications, including mining, metallurgy, construction, chemical industry, electricity, rail transportation and other fields.

Continuous technological innovation: The wear-resistant materials industry continues to innovate in material research and development and process technology. The current situation analysis of the wear-resistant materials industry points out that the development and application of new wear-resistant materials are constantly emerging, such as polymer composite materials, ceramic materials, metal coatings, etc. These new materials have better wear resistance and service life, and can meet the needs of different industries for wear-resistant materials.

Enhanced environmental awareness: With the strengthening of environmental awareness, the wear-resistant materials industry is also moving towards a green and sustainable direction. Enterprises have begun to focus on the research and development of environmentally friendly wear-resistant materials, reduce the impact on the environment, and promote the recycling of resources.

Intensified international competition: With the development of globalization, the wear-resistant materials industry faces fierce competition from home and abroad. Domestic enterprises need to improve their technical level and product quality, continuously enhance their competitiveness, and actively explore the international market.

Improved industrial chain: The industrial chain of the wear-resistant materials industry has gradually improved, covering raw material supply, production and manufacturing, sales and after-sales service. At the same time, some large enterprises have strengthened industrial chain integration and brand building through mergers and acquisitions, cooperation and other means.