How to prolong the service life of the cone mantle and concave of the cone crusher

2025-01-15

The cone mantle and the concave are the main components that crush materials together in the Cone Crusher, and are also the main wear-resistant parts in the cone crusher. When the cone crusher is in operation, the cone mantle will move in a trajectory, and the distance from the concave will sometimes be close and sometimes far away. The material is crushed by the repeated squeezing and impact of the cone mantle and the concave. At this time, part of the material will be discharged from the open-edge discharge port. In the cone crusher, the cone mantle and the concave will inevitably wear out after being used for a period of time. Due to different degrees of wear, when the thickness of the cone mantle and the concave of the cone crusher is worn to two-thirds, or cracks occur, and the discharge port is enlarged to the point where it cannot be adjusted, it needs to be replaced. In general, the factors that affect the crushing effect and service life of the cone mantle and the concave are mainly the following: stone powder content and stone moisture, stone hardness and particle size, feeding method, and material selection of the cone mantle and the concave itself.

1. Stone powder content and stone humidity

When the cone crusher is working, if the stone powder content and humidity of the material are relatively high, it will cause the material to adhere to the cone mantle and the concave during crushing. Over time, it will not only reduce production efficiency, but also corrode the cone mantle and the concave, reducing their service life.

For materials with a relatively high stone powder content, they should be sieved once before crushing, so that too much fine powder can be avoided during crushing. For materials with high humidity, certain measures should be taken to reduce the moisture content before crushing, such as natural drying or mechanical drying.

2. Hardness and particle size of stone

Depending on the hardness of the crushed material of the cone crusher, the degree of wear of the cone mantle and the concave is also different. The higher the hardness of the material, the more difficult it is to crush, the greater the impact load that the cone mantle and the concave bear in production, and the service life will be shortened accordingly; in addition, when the hardness of the ore is the same, the larger the particle size of the ore entering the crushing chamber, the more serious the wear of the liner and the service life will be shortened.

3. Feeding method The feeding method of the cone crusher also has a certain impact on the service life of the cone mantle and the concave. If the feeding device of the cone crusher is improperly installed, or too much material is put into the crushing chamber, it will cause uneven feeding, material blockage in the crushing chamber and other faults, which will cause the cone mantle and the concave to be subjected to excessive force on one side, increase the cutting wear of the ore, cause serious damage to the liner, and ultimately reduce the service life.

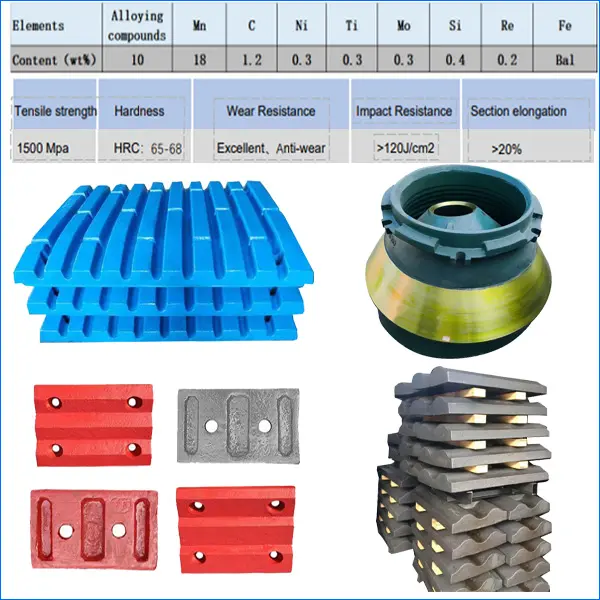

4. Material selection for the cone mantle and the concave When selecting materials, choose a compound alloy material synthesized by a new process with high manganese steel as the base material. The compound alloy material produced by Chengdu Zhixin Refractory Technology Co., Ltd. combines high hardness and high toughness, breaking the bottleneck of high hardness and low toughness, and high toughness and low hardness of traditional wear-resistant parts. The tensile strength of the base material is greater than 1500MPa, and the working hardness is greater than HRC65, which can effectively extend the service life of the cone mantle and the concave of the cone crusher by two times.