Jaw Crushers are widely used in metallurgy, mining, construction, highway and other industries. They can crush river pebbles, basalt, diabase, construction waste and other materials into a particle size of 10-40mm. They have stable operation, high yield rate and uniform size, which can bring a larger market and higher profits to the company's production. The working principle of the jaw crusher is that the motor drives the belt and pulley to move the movable jaw plate up and down through the eccentric shaft. When the movable jaw plate rises, the angle between the toggle plate and the movable jaw plate becomes larger, thereby pushing the movable jaw plate closer to the fixed jaw plate. At the same time, the material is crushed or split to achieve the purpose of crushing. When the movable jaw plate descends, the angle between the toggle plate and the movable jaw plate becomes smaller, and the movable jaw plate leaves the fixed jaw plate under the action of the pull rod spring. At this time, the crushed material is discharged from the lower opening of the crushing chamber.

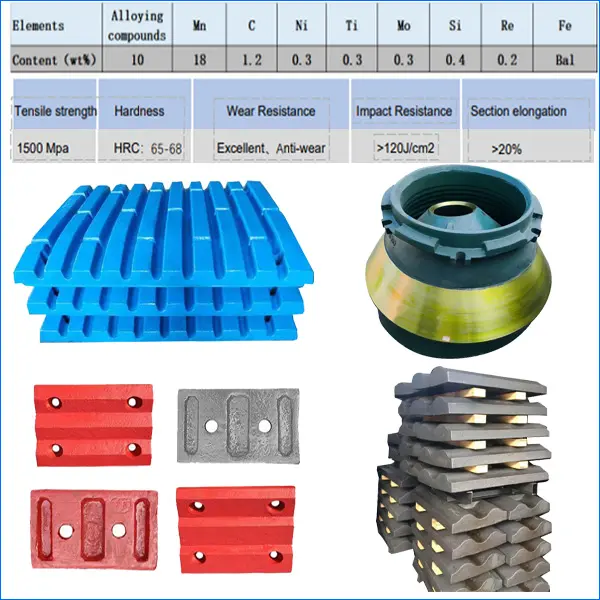

Jaw crushers can be used in conjunction with mineral processing equipment and sand and gravel equipment, or they can be used alone. They are widely used for coarse and medium crushing of ores, but many parts will be worn after long-term operation. After the installation and commissioning of the jaw crusher, many manufacturers only know how to produce it, but ignore the operation of the equipment, resulting in serious wear of the jaw plate. Therefore, if you want to increase the service life of the jaw plate, you can consider aspects such as material selection, design, assembly, and improvements during use. First of all, when selecting materials, choose a compound alloy material synthesized using a new process with high manganese steel as the base material. This material combines high hardness and high toughness, breaking the bottleneck of high hardness and low toughness, or high toughness and low hardness of traditional wear-resistant parts. The tensile strength of the base material is greater than 1500MPa, and the working hardness is greater than HRC65, so that the service life of the jaw plate can be effectively extended by two times. Secondly, when designing, the jaw plates of the fixed jaw and the movable jaw should have tooth peaks facing tooth valleys. In this way, in addition to the extrusion effect on the material during crushing, there is also a bending effect, and the material is easier to crush. At the same time, in order to extend the service life of the jaw plate, the jaw plate of small and medium-sized crushers should be designed to be symmetrical in shape, so that the lower part can be turned around for use after wear. The jaw plate of a large jaw crusher should be designed to be symmetrical to each other so that the jaw plates can be exchanged for use after wear. Furthermore, during assembly, the jaw plate needs to be firmly attached to the cast steel adjustment seat, and the two should be leveled. Soft metal should be used as a gasket between the jaw plate and the adjustment seat, and fastened with bolts. When the crusher is working, the jaw plate should not be loose, otherwise the jaw plate will be worn or easily broken, reducing the service life of the jaw plate. Therefore, the jaw plate must be installed well during assembly to extend the service life of the jaw plate. Finally, during production, the material directly acts on the jaw plate, and the crushing force is very large, especially when crushing materials with very high hardness, which causes the bolts for installing the jaw plate to vibrate and the nuts to loosen, causing the jaw plate to wear more and produce a lot of noise. In severe cases, the jaw plate falls off or breaks, causing the equipment to stop, affecting normal production. Therefore, it is necessary to carry out proper pretreatment of the materials, such as screening and crushing, to reduce the impact and wear of large pieces of materials on the jaw plate, thereby reducing costs and improving work efficiency.