How to improve the service life of ball mill lining

2025-01-15

Ball mill is a kind of grinding equipment commonly used in industrial production, and is widely used in mineral processing, building materials and chemical products. As an important part of the ball mill, the performance of the ball mill liner directly affects the grinding efficiency and the service life of the ball mill. Therefore, improving the service life of the ball mill liner is of great significance to reducing production costs and improving production efficiency. The following are some effective measures to improve the service life of the ball mill liner.

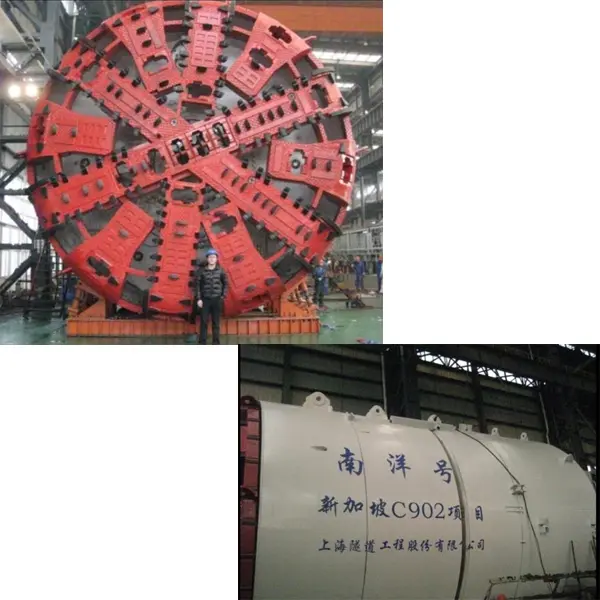

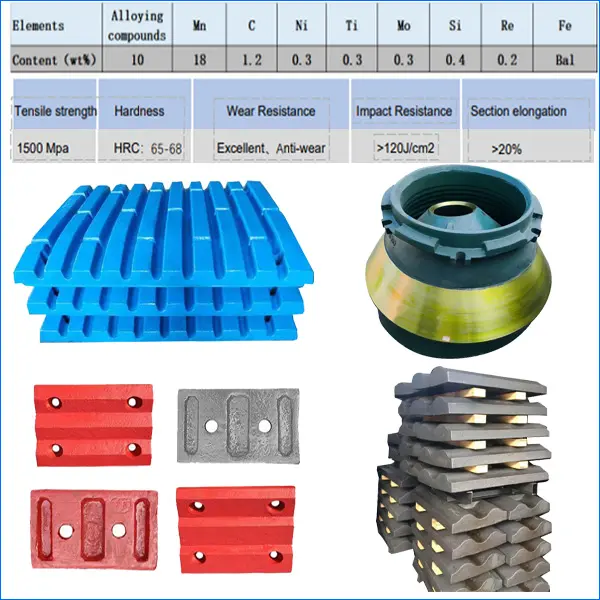

1. Choose the right ball mill liner material. The choice of liner material is one of the key factors affecting its service life. When selecting materials, choose a compound alloy material synthesized by a new process with high manganese steel as the base material. This material produced by Chengdu Zhixin Refractory Technology Co., Ltd. combines high hardness and high toughness, breaking the bottleneck of high hardness and low toughness, and high toughness and low hardness of traditional wear-resistant parts. The tensile strength of the base material is greater than 1500MPa, and the working hardness is greater than HRC65, so that the service life of the ball mill liner can be effectively extended by two times.

2. Optimize liner design The design of the liner includes shape, size and installation method. Reasonable liner design can improve grinding efficiency and reduce liner wear. For example, the use of corrugated or stepped liners can increase the fluidity of the material, reduce the residence time of the material on the liner, and thus reduce wear. At the same time, the installation method of the liner also has a certain impact on the grinding effect and liner wear. For example, floating installation can reduce local wear of the liner.

3. Strictly control grinding conditions Grinding conditions include the type, size, filling rate and grinding concentration of the grinding medium. Strictly controlling these conditions can reduce ball mill liner wear. For example, selecting appropriate grinding media and filling rate can ensure uniform distribution of media and materials during grinding and avoid local wear. At the same time, controlling the grinding concentration within a suitable range can reduce the impact and wear of the material on the liner.

4. Regular inspection and maintenance Regular inspection and maintenance of the ball mill and its liner is an important measure to extend the service life of the liner. The inspection content includes the wear of the liner and the looseness of the fasteners. Once a problem is found, it should be repaired or replaced in time to avoid small problems causing major failures. At the same time, regular lubrication and cleaning of the ball mill can reduce the wear of the liner caused by friction and corrosion.

5. Train operators The skills and experience of operators directly affect the operating efficiency of the ball mill and the service life of the liner. Therefore, regular training of operators to improve their understanding of ball mill operation and maintenance is an effective way to increase the service life of the liner.

6. Reasonable planning of grinding process Reasonable grinding process planning can reduce the wear of materials on the liner. For example, by optimizing the grinding process and reducing the residence time of materials in the ball mill, the wear of the liner can be reduced. At the same time, according to the nature of the material and the grinding requirements, selecting appropriate grinding process parameters, such as grinding fineness, grinding time, etc., can also help extend the service life of the ball mill liner.