Classification of wear-resistant materials and their application in the crushing industry - Advantages of Zhixin Refractory High Manganese Steel Alloy Wear-resistant Plate

Wear-resistant materials are key materials in the industrial field to resist wear and extend the life of equipment. They are widely used in mining, metallurgy, building materials, electricity, glass, aggregates, quarries and other industries. According to the composition and performance characteristics, wear-resistant materials are mainly divided into the following categories:

- Metal wear-resistant materials: such as high manganese steel, alloy steel, wear-resistant cast iron, etc., with high strength and high toughness, suitable for impact wear conditions.

- Ceramic wear-resistant materials: such as alumina, silicon carbide, etc., with high hardness but high brittleness, suitable for low impact and high wear environments.

- Composite materials: such as metal-ceramic composite plates, combining the toughness of metals and the hardness of ceramics, suitable for complex working conditions.

- Polymer wear-resistant materials: such as ultra-high molecular weight polyethylene, suitable for light load and corrosive environments.

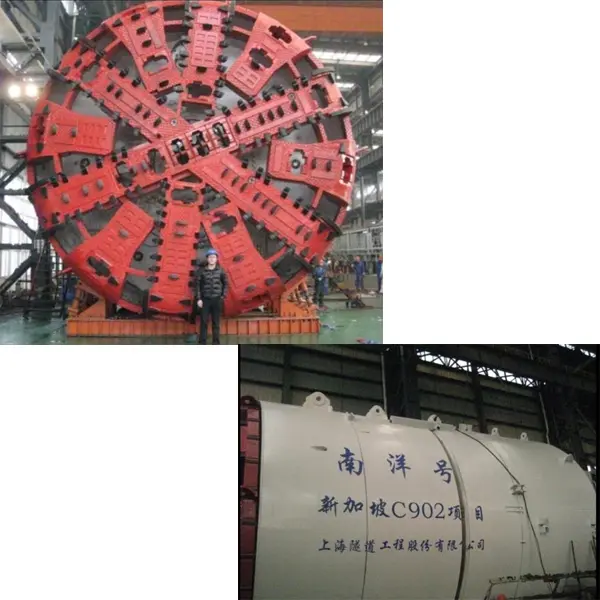

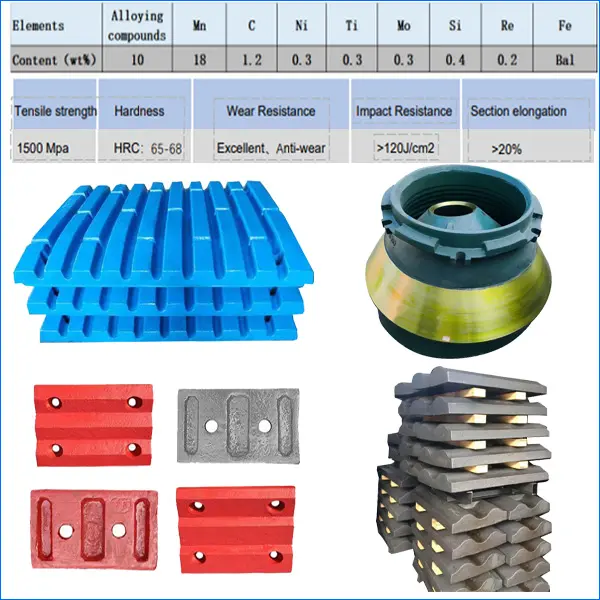

In the crushing industry, high impact and high wear conditions place extremely high demands on wear-resistant materials. The high manganese steel alloy developed by Zhixin Refractory Technology Co., Ltd. has become an ideal choice for key components such as jaw crusher jaw plates, cone crusher liners, ball mill liners, impact crusher liners, and wear-resistant steel plates due to its excellent performance.

**Ultra-high tensile strength and excellent impact resistance**

Zhixin Refractory's high manganese steel alloy wear-resistant plate has a tensile strength of up to 1500 MPa, which is much higher than ordinary high manganese steel (about 800-1000 MPa). It can withstand the huge impact force generated by the crusher when crushing hard ores, effectively prevent fracture and deformation, and extend the service life of the equipment.

**Ultra-high hardness, significantly improved wear resistance**

The hardness of this material reaches 65-68 HRC, which is much higher than traditional high manganese steel (usually 50-55 HRC), which can greatly reduce the loss caused by material wear. For example, in the application of jaw crusher jaw plates, its wear resistance is 2-3 times higher than that of ordinary materials, reducing the frequency of shutdown and replacement and improving production efficiency.

**Optimized alloy composition, strong fatigue resistance**

By adding alloy elements such as chromium, molybdenum, and nickel, Zhixin Refractory's high manganese steel wear-resistant plate not only improves hardness and strength, but also enhances fatigue resistance. It can still maintain stability under repeated impact loads, and is particularly suitable for parts such as ball mill liners that are subjected to long-term cyclic stress.

**Precision manufacturing process to ensure product consistency**

Adopting advanced heat treatment process and precision casting technology, Zhixin Refractory's wear-resistant plate has uniform structure and no internal defects, ensuring that each liner and jaw plate has stable performance and reducing early failure problems caused by uneven materials.

**Wide applicability to meet diverse needs**

This material can be widely used in various types of crushing equipment, such as:

* Jaw crusher jaw plate: impact resistance, wear resistance, suitable for crushing high-hardness ores such as granite and basalt.

* Cone crusher liner: high hardness reduces wear and extends replacement cycle.

* Ball mill liner: high strength fatigue resistance, reducing maintenance costs.

* Impact liner: ultra-high wear resistance, improve crushing efficiency.

* Welding steel plate: suitable for wear-resistant surfacing repair, economical and efficient.

With ultra-high strength, high hardness, excellent impact resistance and wear resistance, the high manganese steel and chemical alloy wear-resistant plate of Zhixin Refractory Technology Co., Ltd. has shown significant advantages in the crushing industry, helping customers reduce maintenance costs and improve production efficiency. In the future, with the continuous innovation of material technology, Zhixin Refractory will continue to promote the upgrading of wear-resistant materials and provide more reliable solutions for the global mining and crushing industries.