Advantages and challenges of impact crusher in practical application

2025-01-15

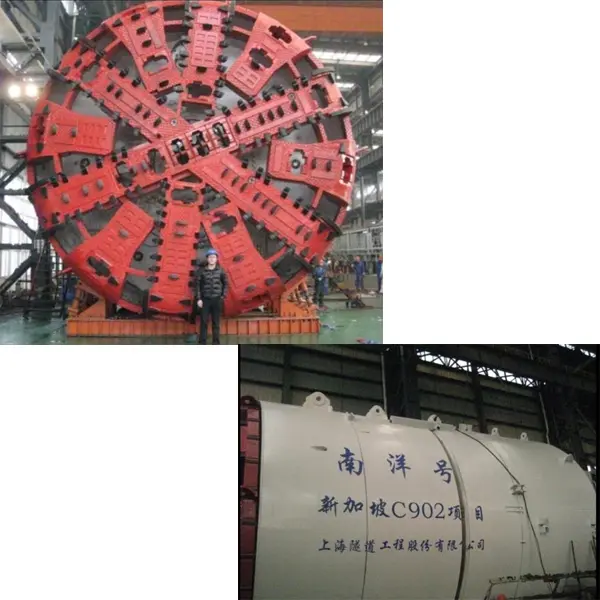

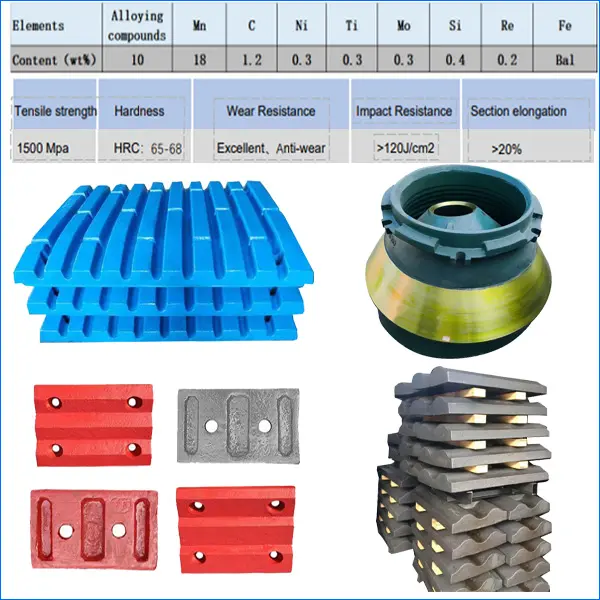

Impact crusher is a machine that uses impact energy to crush materials. Its working principle is that the material falls directly from the machine's material inlet into the high-speed rotating turntable, and under the action of high-speed centrifugal force, it collides and crushes with the flying stones around the turntable at high speed. The material forms an eddy current motion between the turntable and the casing, causing multiple mutual impacts, friction, and crushing, and finally discharged directly from the bottom. The main components of the impact crusher include springs, railings, front and rear impact frames, impact plate, square steel, impact liner bolts, flip cover device, main shaft, plate hammer, rotor frame, etc. Among them, the function of the impact plate is to withstand the impact of the material knocked out by the plate hammer, crush the material, and bounce the crushed material back to the impact area for impact crushing again. The impact plate is generally welded with steel plates and equipped with a wear-resistant liner.

Impact crushers are widely used in many industries due to their advantages such as high efficiency, low energy consumption, easy adjustment and maintenance, but they also need to face challenges such as wear, noise and humidity control.

Advantages of impact crushers:

1. Wide range of material adaptability: impact crushers can handle hard materials with a compressive strength of no more than 350 MPa, including granite, limestone, river pebbles, etc., suitable for building materials, metallurgy, chemical industry, hydropower and other industries.

2. Diversity of discharging particle size adjustment: impact crushers can adjust the discharging particle size by adjusting the rotor speed, distributor and grinding chamber gap, which provides flexibility for production with different needs.

3. Convenient replacement of wearing parts: the wear of the hammer mainly occurs on the side facing the material, with high metal utilization and easy replacement, reducing maintenance time and cost.

4. High crushing efficiency and low energy consumption: the impact crusher has a high crushing efficiency and low energy consumption, generally 0.5~1.3kw.h/t, which is more energy-efficient than Jaw Crushers and roller crushers.

5. Simple equipment structure and easy maintenance: The impact crusher has a simple structure and light weight, and is relatively easy to maintain and overhaul.

Challenges of impact crushers:

1. Wear of wearing parts: Although the hammer and impact plate of the impact crusher are designed to have a long service life, the wear of these parts is still a huge test when handling hard or abrasive materials.

2. Noise problem: The impact crusher may produce a lot of noise during operation, which may be a challenge in some applications that require a low-noise environment.

3. Rotor dynamic balancing requirements: The dynamic balance of the rotor is crucial to the normal operation of the impact crusher. Imbalance may cause vibration and equipment damage.

4. Material moisture and particle size restrictions: Although the impact crusher is suitable for handling materials with a large amount of moisture, excessive humidity may still cause clogging problems, and there are also certain restrictions on the feed particle size.

5. Equipment investment cost: For some small and medium-sized enterprises, the initial investment cost of the impact crusher may be relatively high, especially when multiple equipment or high-specification equipment is required.