A complete guide to the use and maintenance of jaw crusher tooth plate

In the mining, building materials, metallurgy, aggregate, glass and other industries, jaw crusher is the core equipment for primary crushing, and its performance directly affects production efficiency and cost. The jaw crusher jaw plate is a key component directly involved in rock crushing in the jaw crusher. Its use status directly determines the working efficiency, energy consumption and maintenance cost of the equipment. How to use and maintain the jaw plate scientifically has become the focus of users. This article will provide you with practical suggestions to help you maximize the value of the jaw plate.

1. Scientific use: key details from installation to operation

**Precise installation to ensure fit**

Before installing the new jaw plate, the contact surface of the bearing seat and the frame must be thoroughly cleaned to avoid impurities affecting stability. It is recommended to use a torque wrench during installation and tighten the bolts symmetrically in stages (it is recommended to tighten to 30%, 70% and 100% of the rated torque in three times) to ensure uniform force. After installation, it is necessary to manually turn the wheel to check the parallelism of the movable jaw and the fixed jaw, and the deviation should be controlled within 2mm.

**Step-by-step running-in to extend initial life**

Before the new jaw plate is put into use, it needs to be run-in at no load for 16-24 hours, followed by a three-day step-by-step load run-in (30% load on the first day, 60% on the second day, and 80% on the third day). This process can form a hardened layer on the surface of the manganese steel jaw plate, and the wear resistance is improved by about 40%.

**Feeding control to reduce abnormal wear**

Strictly control the feed particle size (it is recommended not to exceed 80% of the feed port width), and use an electromagnetic iron remover to remove metal impurities. For materials with high quartz content (SiO2>60%), it is recommended to add a pre-screening process before crushing, which can reduce the jaw plate wear rate by more than 35%.

2. Intelligent maintenance: from daily inspection to periodic maintenance

**Three-dimensional detection method**

After daily shutdown, use the "look, measure, and record" three-in-one inspection method: visually check whether there are cracks or abnormal protrusions on the surface of the jaw plate, use a caliper to measure the wear of the tooth height (if it exceeds 20% of the original height, consider replacing it). Record the daily crushing amount and current fluctuation data, and establish a wear curve model.

**Lubrication system gold standard**

Use lithium-based grease (NLGI grade 2) to replenish once every 8 hours, and control the bearing seat temperature at ≤75℃. Special reminder: Synthetic hydrocarbon grease should be used instead during the high temperature period in summer, which can reduce the friction coefficient by 15%.

**Innovative surfacing repair technology**

When the jaw plate is partially worn, JYD-616 welding rods can be used for multi-layer surfacing repair. It needs to be preheated to 300-350℃ before repair, and keep warm and cool slowly after welding. According to tests, the scientifically repaired jaw plate can restore more than 90% of the original performance, and the cost of a single repair is only 18% of that of a new part.

3. Upgrade plan: material selection and structural optimization

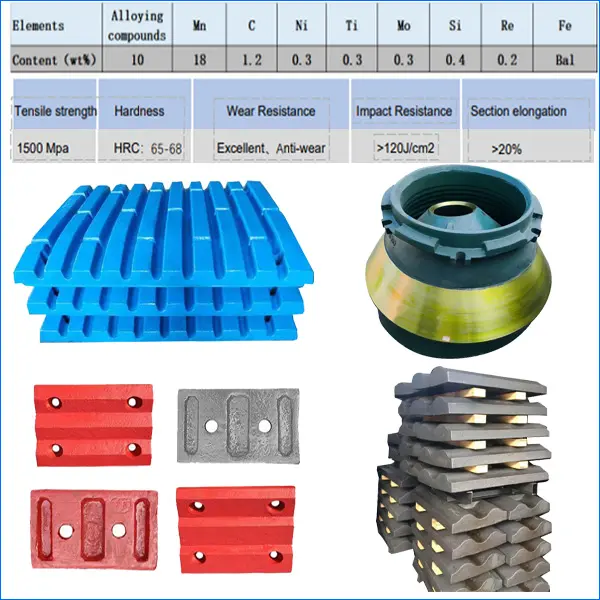

**Gradient material application**

For crushing hard rock conditions such as basalt and granite, it is recommended to use the ultra-wear-resistant alloy jaw plate (surface hardness HRC62-68, tensile strength 1500MPa) cast by Zhixin Refractory Materials, which has a service life 2-3 times longer than traditional high manganese steel.

**Intelligent monitoring system**

Install wireless vibration sensors and temperature monitoring modules to analyze the jaw plate working conditions in real time through the cloud platform. When an abnormal vibration spectrum is detected (such as a sudden increase in high-frequency components of 5-8kHz), an automatic warning is issued, and the risk of cracks can be predicted 48 hours in advance.

According to statistics, scientific maintenance can extend the service life of the jaw crusher jaw plate by 50%-80%, and the crushing cost per ton can be reduced by 0.15-0.3 yuan. Choosing Zhixin jaw plate and wear-resistant parts can greatly increase the service life and reduce production costs.