In the quarry application of mining machinery, cone crusher is a key equipment

Working principle

● Cone crusher is mainly composed of moving cone and fixed cone. The motor drives the eccentric sleeve to rotate through the pulley or coupling, and then makes the moving cone do pendulum motion. When the ore enters the crushing chamber from the feed port, the distance between the moving cone and the fixed cone changes continuously. When approaching, the ore is crushed by extrusion, bending and impact; when the moving cone leaves, the crushed ore moves downward under the action of gravity and is continuously crushed until the particle size meets the requirements and is discharged from the discharge port.

Product display

Structural features

● Crushing chamber design: There are many types of crushing chambers, such as standard, medium, and short head. The standard type is suitable for two-stage and medium crushing; the short head type is used for three-stage and fine crushing. The shape of the crushing chamber can make the ore more reasonably crushed in it, effectively improving the crushing efficiency.

● Adjustable discharge port: The size of the discharge port can be easily changed through the adjustment device to control the particle size of the product to meet different production needs.

● Good sealing: The overall sealing of the equipment is good, which can effectively reduce dust spillage, which is very important in the quarry environment, can improve the working environment and reduce equipment wear.

Advantages in the quarry

● Efficient crushing: With a high crushing ratio, it can crush larger-sized stones into a smaller particle size range at one time, with high production efficiency, suitable for large-scale quarrying operations.

● Good product quality: The product particle size can be accurately controlled, and the produced stones are relatively regular in shape, mostly cubic, which can meet the high requirements of stone quality in the construction and other industries.

● Strong adaptability: It can handle stones of various hardness, such as granite, limestone, basalt, etc., and can work stably under different working conditions.

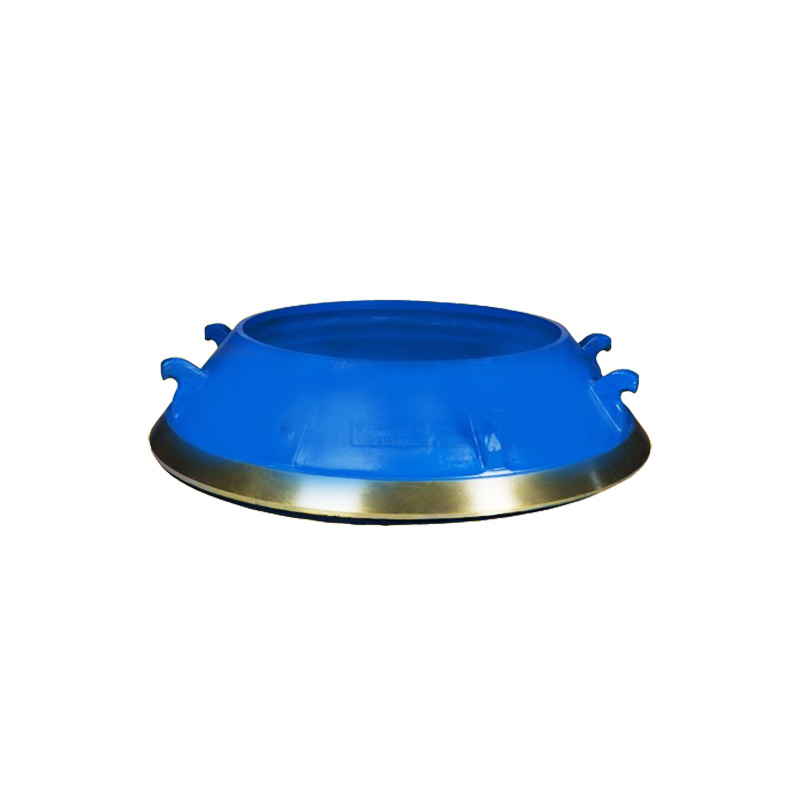

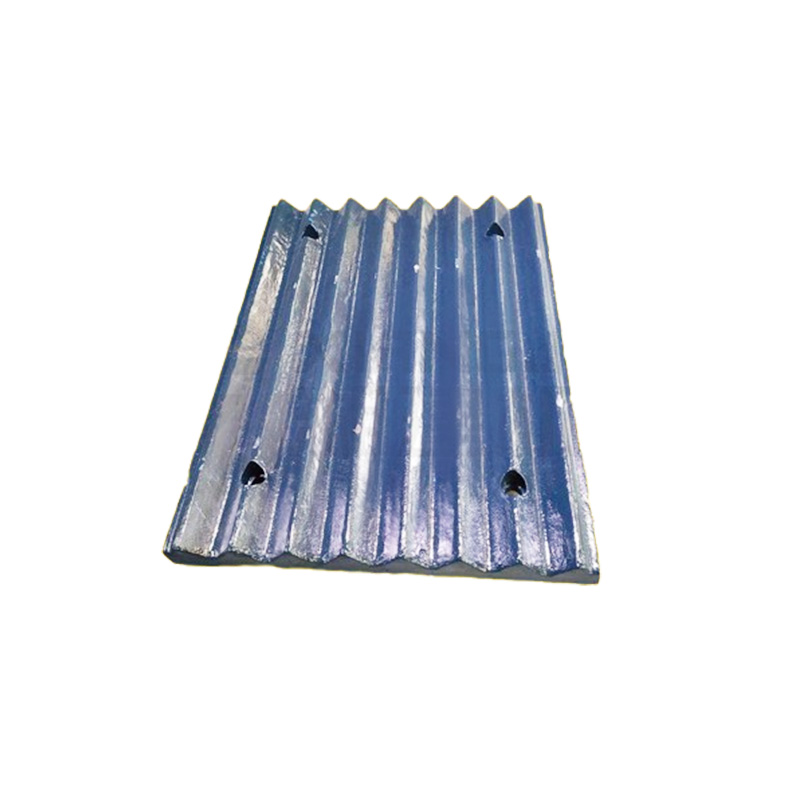

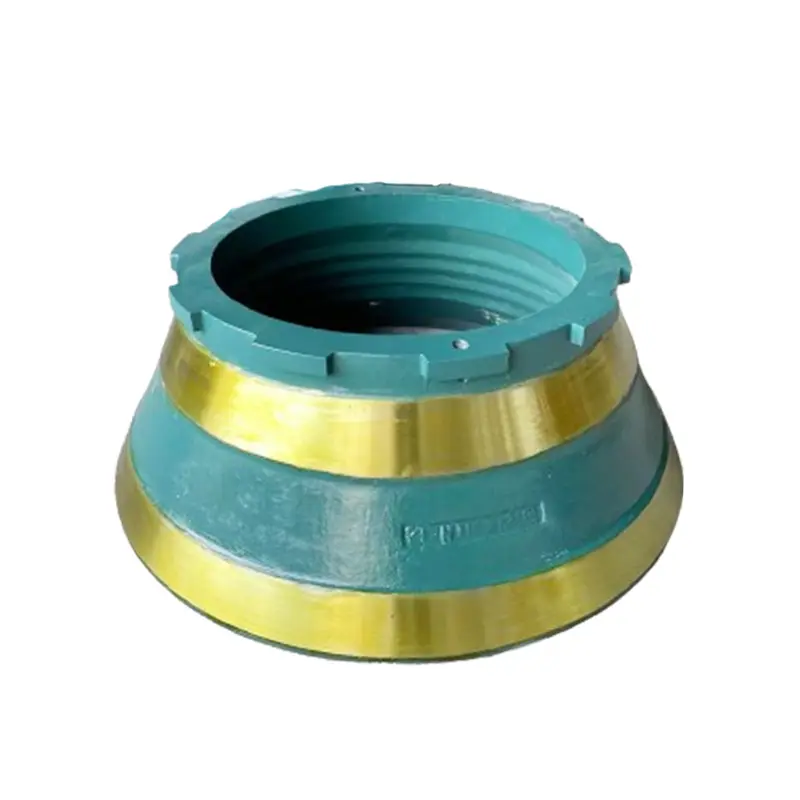

● Cone crushing wall is the key component of cone crusher.

Main function

● Cone crushing wall is used in conjunction with mortar wall. When cone crusher is working, through the swinging motion of moving cone, crushing wall squeezes and grinds the stone entering the crushing chamber, so that the stone is crushed into the required particle size.

Material characteristics

● High manganese steel: the most widely used. This material has good toughness. When it is impacted and rubbed by ore, the surface will produce work hardening, and the hardness can be improved to a certain extent, so it has good wear resistance.

● New composite materials: Crushing walls made of materials such as high chromium cast iron are also gradually emerging. High chromium cast iron has high hardness and excellent wear resistance. It is suitable for crushing operations of some high-hardness ores and can effectively extend the service life of the crushing wall.

● Ore characteristics: The higher the hardness of the ore and the stronger the abrasiveness, the faster the wear rate of the crushing wall. For example, the wear of the crushing wall when crushing granite will be much faster than when crushing limestone.

● Equipment operating parameters: If the feeding speed of the cone crusher is too fast and the feeding particle size is uneven, the load on the crushing wall will be unstable, resulting in increased local wear and shortening of the service life.

● Equipment maintenance: Regular maintenance of the crusher, including timely cleaning of the crushing chamber and lubrication of related parts, can reduce abnormal wear of the crushing wall and extend its service life.

Installation and replacement

● Installation: During installation, ensure that the crushing wall fits tightly with the moving cone. Generally, special bolts and other connectors are used for tightening, and the installation accuracy must be ensured to avoid installation deviation and other situations that affect the normal operation of the crusher.

● Replacement: When the crushing wall is worn to a certain extent, affecting the crushing effect (such as the product particle size does not meet the requirements) or when it is damaged, it needs to be replaced in time. The replacement process must be carried out strictly in accordance with the equipment's operating manual to ensure that the new crushing wall is installed correctly.