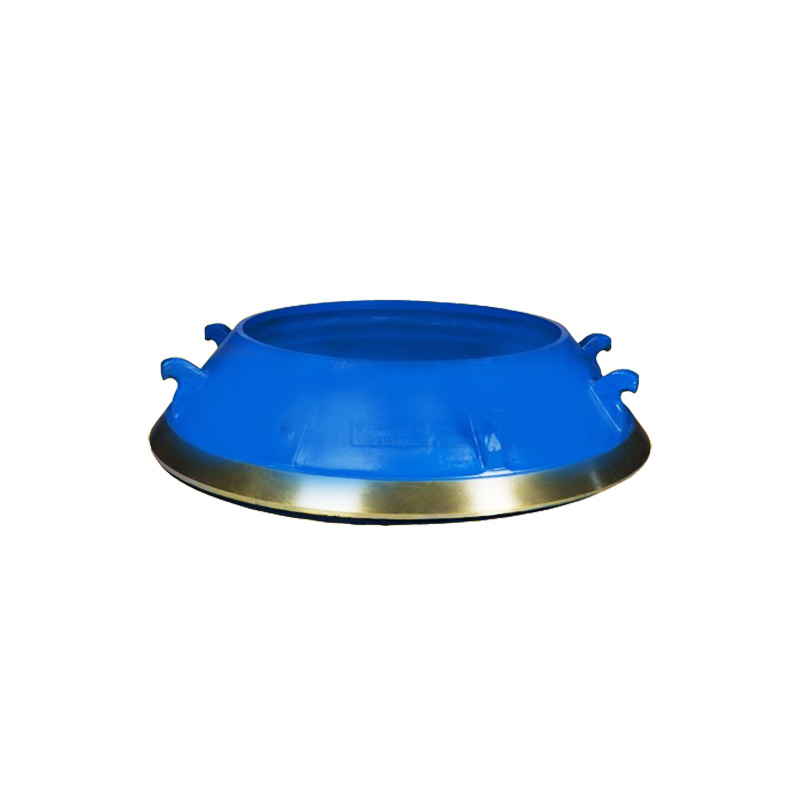

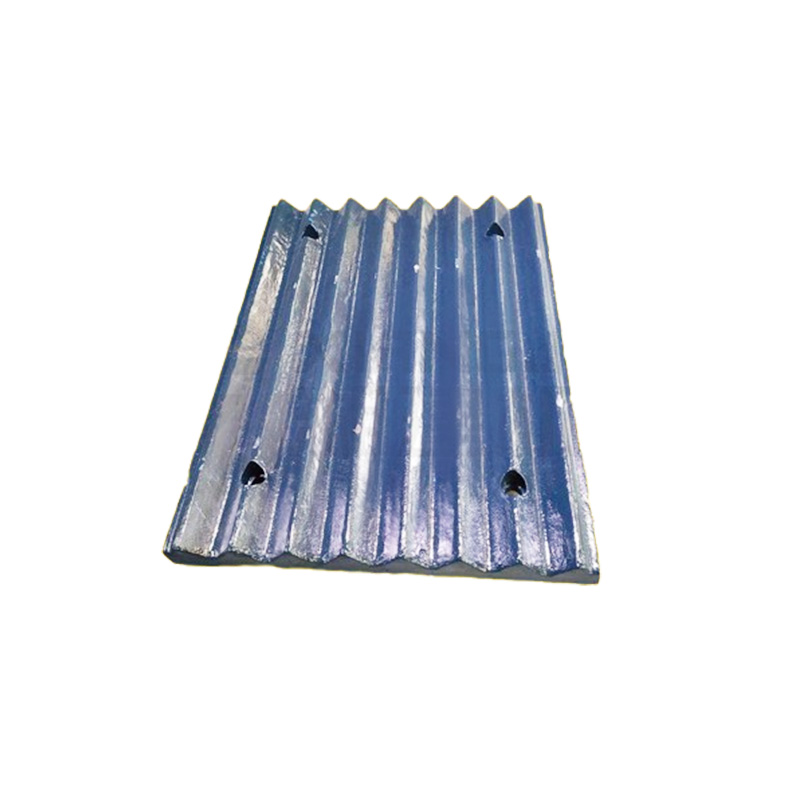

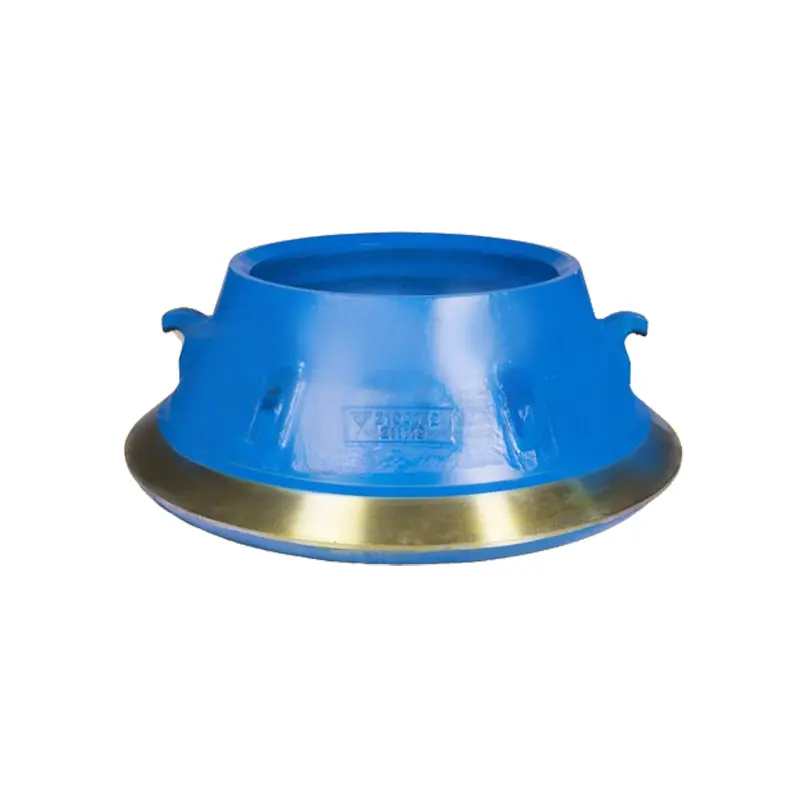

High manganese steel cone crushing wall is a key wear-resistant component in the cone crusher.

Features

● High wear resistance: Under large impact or contact stress, the surface layer is rapidly hardened, and the hardening index is 5-7 times higher than other materials, which greatly improves wear resistance.

● Good toughness: It has good plasticity and impact toughness, can withstand the strong impact force generated by the cone crusher when it is working, and is not prone to brittle fracture.

● Good processability: It is easy to cast and process, and can be made into various complex shapes and sizes to meet the needs of different types of cone crushers.

Product display

Working principle

When the cone crusher is working, the motor drives the eccentric sleeve to rotate, and the moving cone rotates and swings under the force of the eccentric sleeve. The high manganese steel crushing wall on the moving cone sometimes approaches and sometimes leaves the mortar wall fixed on the adjustment sleeve, so that the material in the crushing chamber is continuously impacted, squeezed and bent and crushed.

Application scenarios

● Mining industry: widely used in medium and fine crushing of various metal ores such as iron ore, copper ore, gold ore, etc.

● Building materials industry: used to crush limestone, granite, basalt and other stones, and produce sand and gravel for construction.

● Metallurgical industry: treat metallurgical waste slag, and recycle and reuse the useful metal components in the waste slag.

Maintenance and care

● Regular inspection: Regularly stop the machine to check the wear of the crushing wall, observe whether the wear is uniform, whether there is severe local wear or cracks, etc.

● Adjustment and installation: When installing the crushing wall, ensure that it is firmly installed and the gap between the moving cone and the mortar wall is uniform and consistent.

● Control materials: Strictly control the particle size of the material entering the cone crusher to avoid excessively large or hard materials from entering the crushing chamber to prevent excessive wear or damage to the crushing wall.

Material properties

● High wear resistance: Under the impact and friction, the surface is quickly hardened, the hardness is greatly improved, and the wear resistance is significantly enhanced, which can effectively resist the wear of the ore.

● Good toughness: With excellent toughness and impact resistance, it can withstand the huge impact force generated by the mining machinery at work, is not easy to break, and ensures the stable operation of the equipment.

● Machinability: Easy to cast and process, it can be made into crushing walls of various complex shapes and sizes to meet the needs of different mining machinery models.

Production process

● Model making: According to the design drawings, use wood, metal or plastic and other materials to make a model with the same shape and size as the crushing wall for modeling in the casting process.

● Modeling and core making: Fill the modeling materials such as molding sand around the model, take out the model after compaction, and form a casting cavity. For the crushing wall with complex structure, it is also necessary to make a core to form an internal cavity or hole.

● Melting and pouring: Put the high manganese steel raw materials into an electric furnace or other melting furnace for melting. After reaching the appropriate temperature and composition, pour the molten steel into the casting cavity, and cool and solidify to form a high manganese steel crushing wall blank.

● Heat treatment: The crushing wall blank after casting is subjected to heat treatment processes such as water toughening to eliminate casting stress and improve the strength, toughness and wear resistance of the material.

Quality control

● Chemical composition detection: The chemical composition of high manganese steel materials is strictly tested by means such as spectral analysis to ensure that the content of each element meets the standard requirements, such as manganese content is generally 10%-15%, and carbon content is 0.90%-1.50%.

● Hardness test: Use a hardness tester to test the hardness of the crushing wall surface and key parts to ensure that the hardness value is within a reasonable range to meet the wear resistance requirements.

● Flaw detection: Use ultrasonic flaw detection, magnetic particle flaw detection or radiographic flaw detection to detect whether there are cracks, pores, sand holes and other defects inside the crushing wall to ensure product quality.