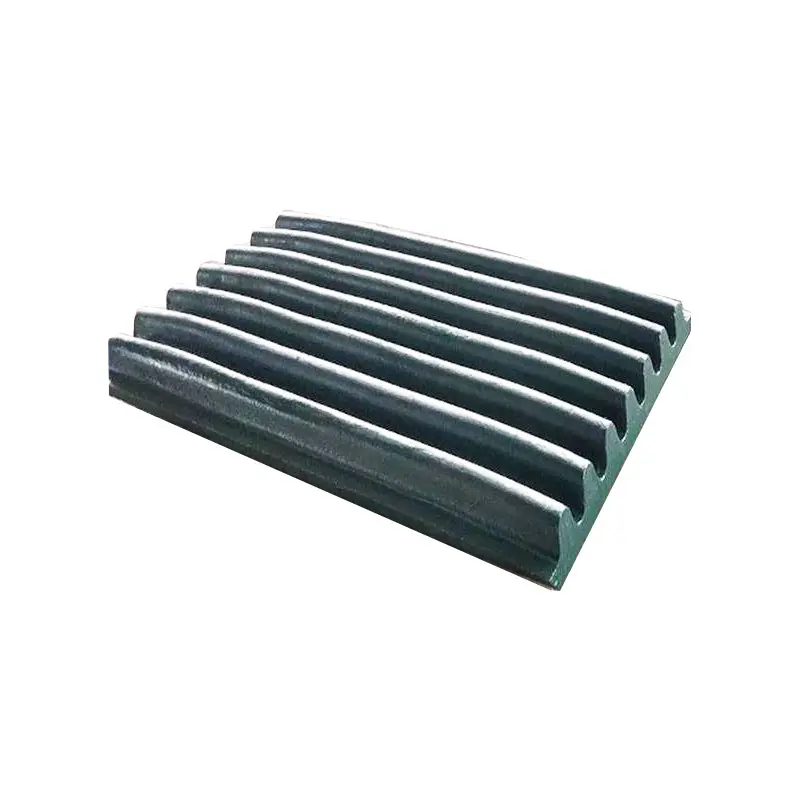

Good Selling Coal Mining Mining Machinery Crusher Jaw Plate

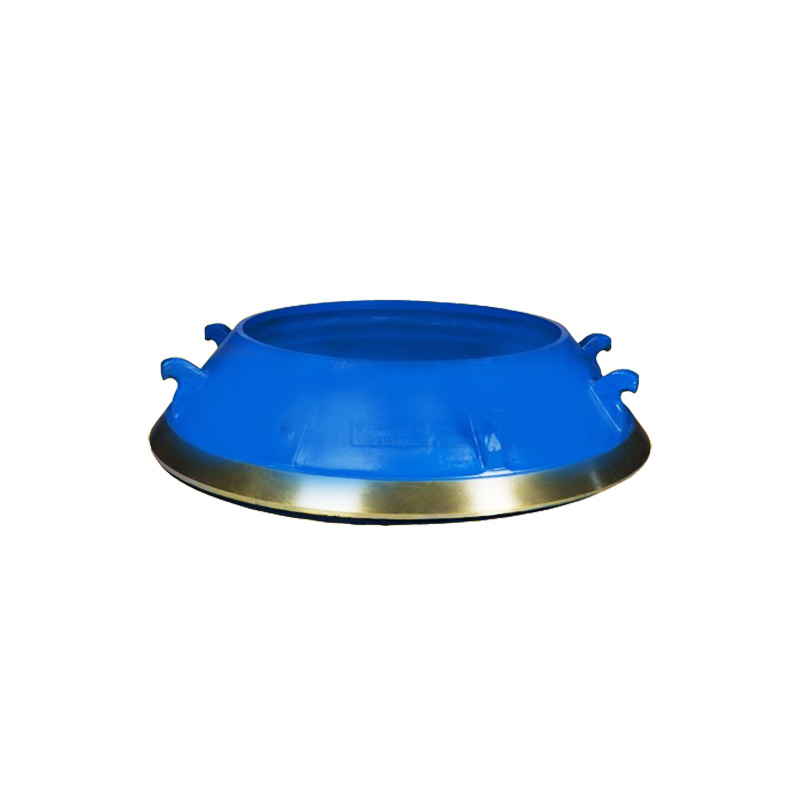

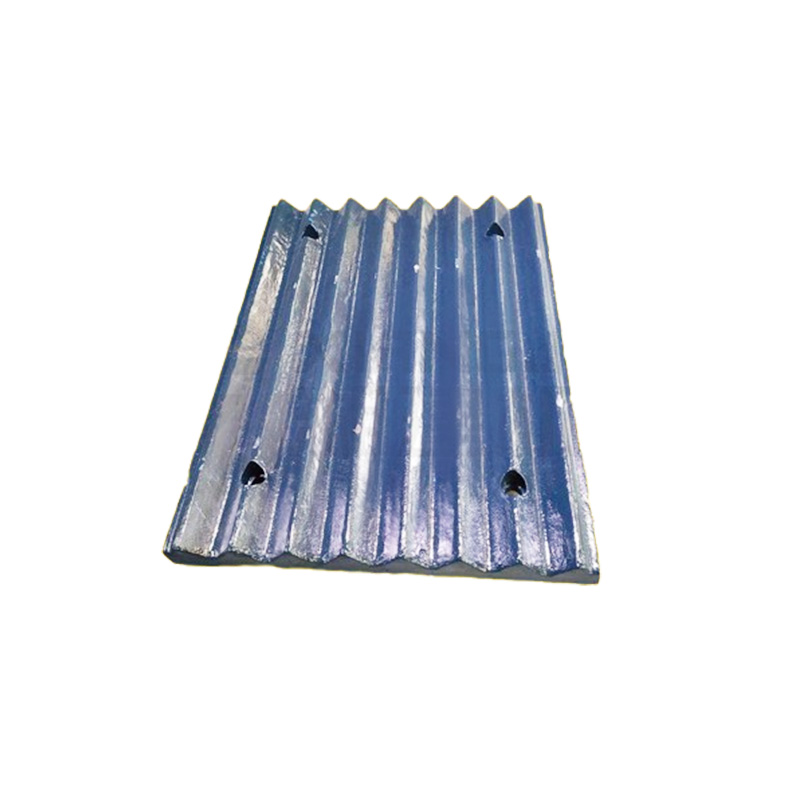

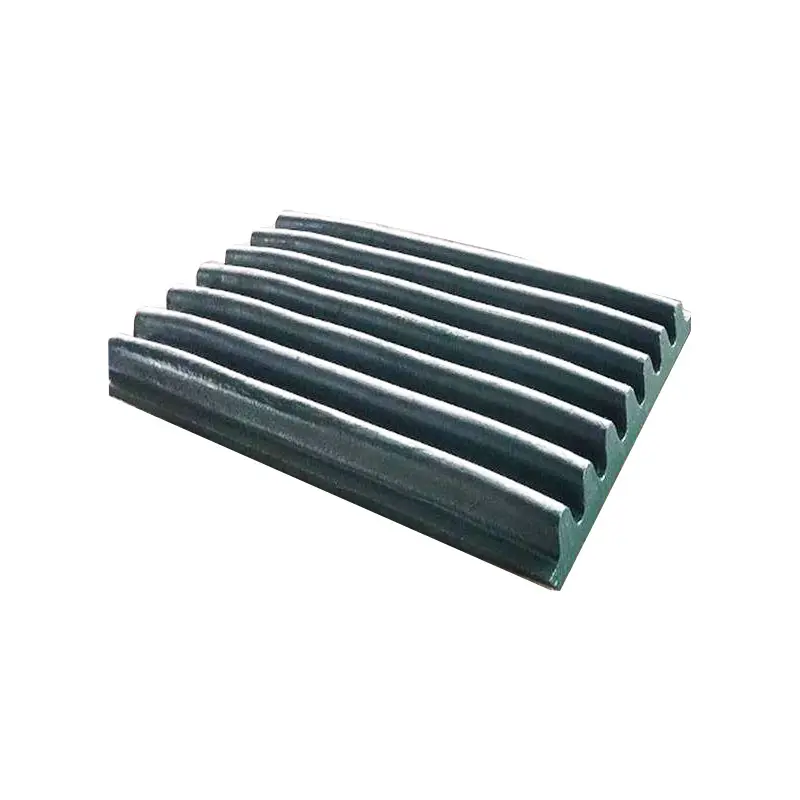

Jaw Crusher Spare Parts

We also can offer the OEM/ODM services of jaw crusher plates. The product can be customized according to your personalized requirements, including the brand, label, painting colors, and packing box. Please offer your design documents or tell us your ideas and our R&D team will do the rest.

1. Materials: High manganese and customized materials.

2. Application: Wear parts for crushers in the quarry, mining, cement aggregate, recycling, shredding and demolition fields etc.

3. Certifications: ISO9001:2005.

4. Production quality testing: Hardness testing, metallographic structure, machinery performance testing, ultrasonic inspection, high frequency infrared carbon and surface analysis etc.

5. Strong wear resistance and long life span, can be used in harsh environment and serious abrasion.

6. Professional: Zhixin has over 10 years working experience in casting and forging process and manufacture.

As we all know, as the crushing time increases, the tooth plate of the crusher will continue to wear and the discharge opening will gradually become larger, which will cause certain difficulties for the next crushing operation.

Product display

What are the ways to adjust the discharge opening of jaw crusher?

1. Gasket adjustment

2. Hydraulic cylinder adjustment

3. Wedge adjustment

4. Double wedge adjustment

In summary, the gasket type has the lowest maintenance cost among several adjustment methods, but this adjustment method must be stopped for adjustment, which is inconvenient to operate and has limited space for personnel adjustment. At the same time, the gasket adjustment cannot achieve step-less adjustment because the gasket thickness is fixed, so this adjustment method is inefficient and will seriously affect production efficiency; the hydraulic cylinder adjustment method is the most convenient and efficient, which can not only reduce the labor intensity of the operator, but also realize functions such as iron removal and cavity cleaning, but the manufacturing cost, maintenance cost and operation and maintenance skills of the workers are high; the wedge adjustment method can achieve automatic adjustment, which is also convenient to operate, with low manufacturing process and cost requirements, and convenient later maintenance.

In fact, the adjustment of the discharge port of the jaw crusher does not need to be changed frequently. Under normal circumstances, the size of the discharge port needs to be adjusted once a month. In addition, in daily production, if the size of the discharge port is found to change greatly, it should be adjusted in time. Through the reasonable adjustment of the discharge port of the jaw crusher and daily maintenance work, unnecessary production losses in construction can be effectively reduced, and the service life of the jaw crusher can be improved, and the comprehensive profit margin of the enterprise can be increased.