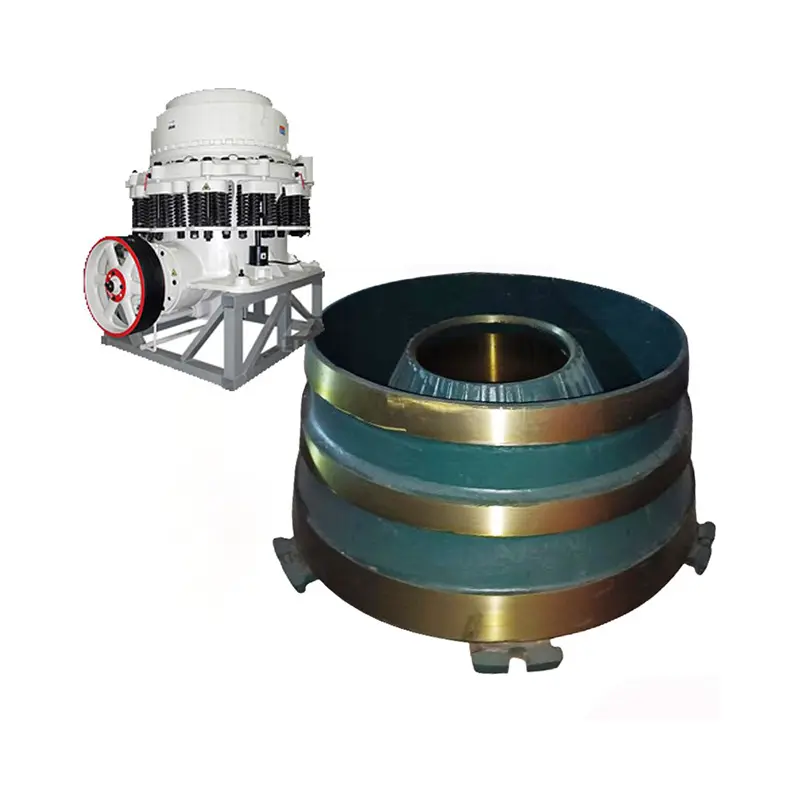

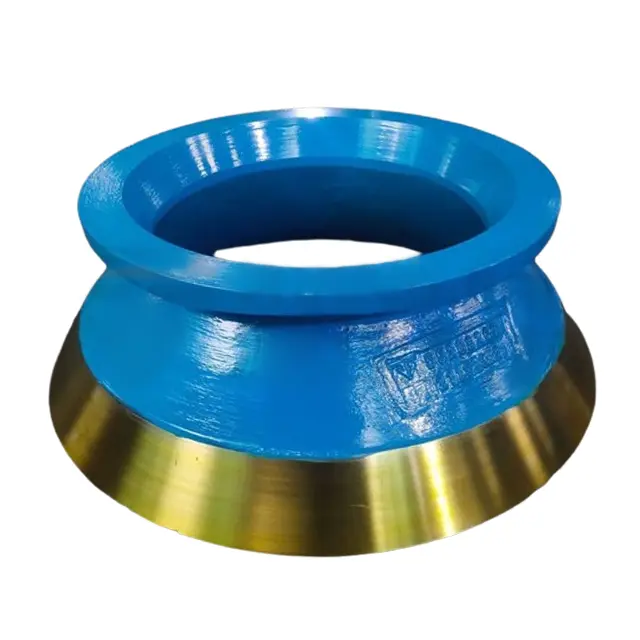

Cone crusher mantle and concave

Product technology

With our phD team unique technology, made the products service life time more durable than normal,extension double. If not live up our promise, you may refund without return.

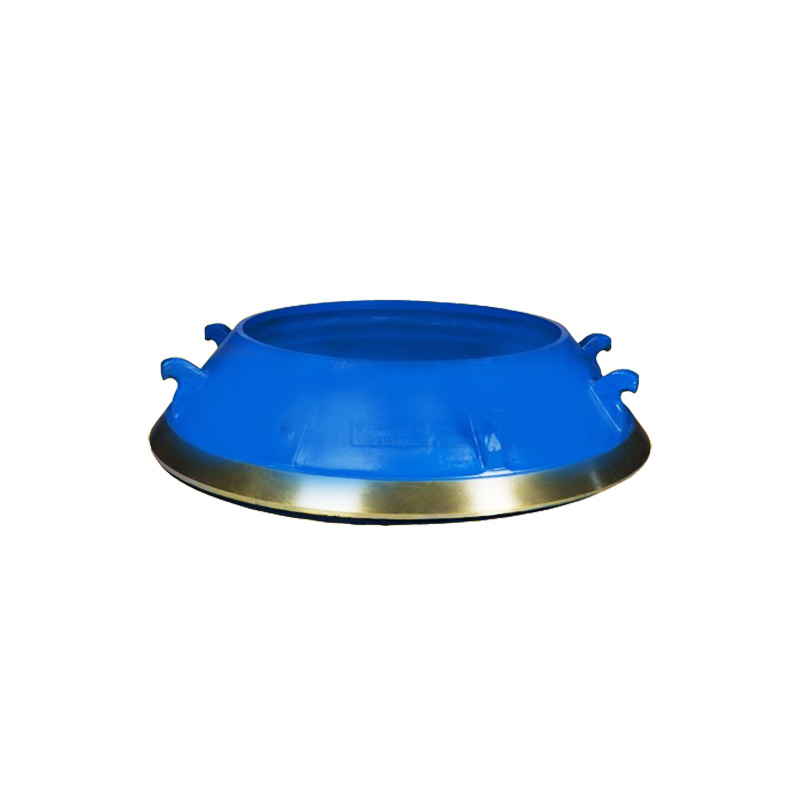

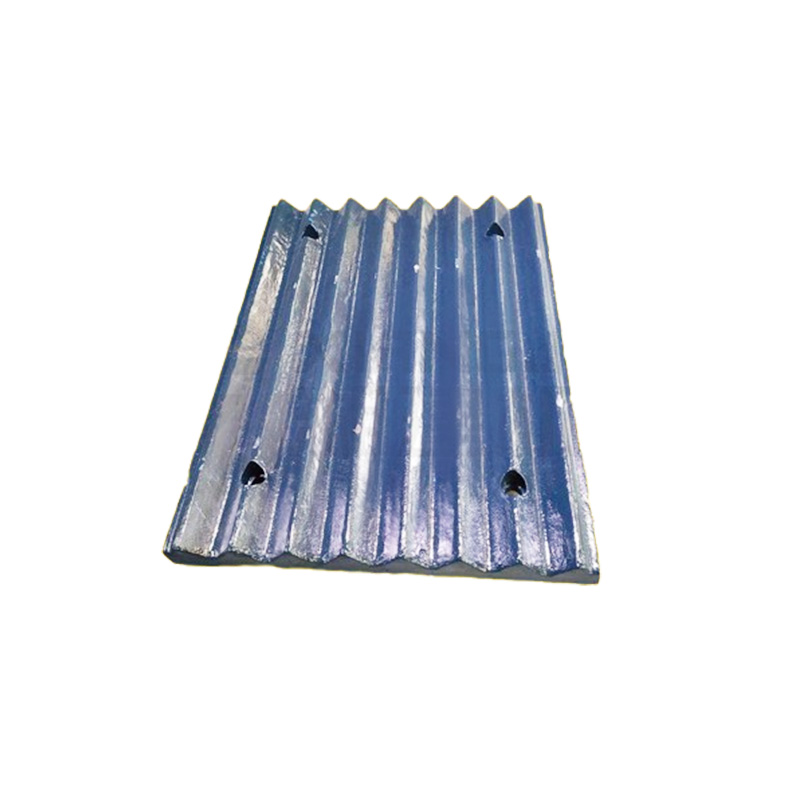

Concave and Mantle Liner Plate is quick wear part. Now we can make the Mn18 and Mn22 cone liner plate wear part , also can make the customized materials requirements. It is durable and robust, widely application to the quarry aggregate plant and the mine, metallurgy, construction materials, ceramic and refractory materials industry or filed. We are still focusing on the the best solution of the Mn steel Matrix ceramic composite jaw plate to the special requirement customer.

Product display

Product material

The main raw materials of high manganese steel casting include manganese, carbon, silicon and other elements .

Manganese(Mn): The main alloying element in high manganese steel, with a content generally above 11%. Manganese can improve the wear resistance, toughness and hardness of high manganese steel, while reducing low-temperature brittleness and hot work hardening tendency.

Carbon (C): The content is usually between 0.9%-1.3%. Carbon can improve the hardness and strength of high manganese steel, but will reduce its toughness and impact resistance.

Silicon (Si): The content is generally between 0.2%-0.5%. Silicon can improve the toughness and impact resistance of high manganese steel, while reducing its brittleness and porosity.

Manganese(Mn): The main alloying element in high manganese steel, with a content generally above 11%. Manganese can improve the wear resistance, toughness and hardness of high manganese steel, while reducing low-temperature brittleness and hot work hardening tendency.

Carbon (C): The content is usually between 0.9%-1.3%. Carbon can improve the hardness and strength of high manganese steel, but will reduce its toughness and impact resistance.

Silicon (Si): The content is generally between 0.2%-0.5%. Silicon can improve the toughness and impact resistance of high manganese steel, while reducing its brittleness and porosity.

Chromium (Cr): The content is usually between 0.5%-2.0%. Chromium can improve the hardness and wear resistance of high manganese steel, while enhancing its oxidation resistance and corrosion resistance.

Molybdenum (Mo): The content is generally not more than 0.3%. Molybdenum can improve the strength and wear resistance of high manganese steel, while enhancing its corrosion resistance.

Cobalt (Co): The content is usually no more than 1%. Cobalt can improve the wear resistance and toughness of high manganese steel, while reducing its hardness and brittleness.

The casting process of the product is usually:

drawing confirmation, mold making, modeling, painting, adding unique process technology, baking, testing, smelting, pouring, heat treatment, cutting, machining, etc.Each product will pass strict quality inspection before leaving the factory to ensure product quality. If now your type can use 60 days,then our high quality type can use 120 days more; if your type can use 120 days,then high quality model can use 240 days more. At same industrial and mining conditions, the service life of our products of conventional high manganese steel are more than double times of our counterparts. If you are not satisfied, you can return it for a refund.

Molybdenum (Mo): The content is generally not more than 0.3%. Molybdenum can improve the strength and wear resistance of high manganese steel, while enhancing its corrosion resistance.

Cobalt (Co): The content is usually no more than 1%. Cobalt can improve the wear resistance and toughness of high manganese steel, while reducing its hardness and brittleness.

The casting process of the product is usually:

drawing confirmation, mold making, modeling, painting, adding unique process technology, baking, testing, smelting, pouring, heat treatment, cutting, machining, etc.Each product will pass strict quality inspection before leaving the factory to ensure product quality. If now your type can use 60 days,then our high quality type can use 120 days more; if your type can use 120 days,then high quality model can use 240 days more. At same industrial and mining conditions, the service life of our products of conventional high manganese steel are more than double times of our counterparts. If you are not satisfied, you can return it for a refund.