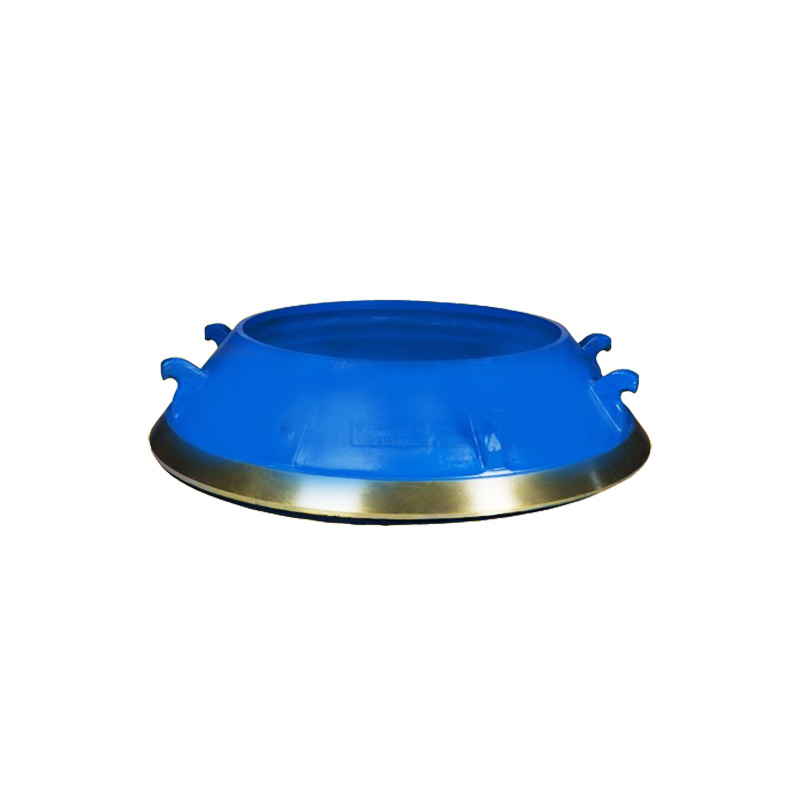

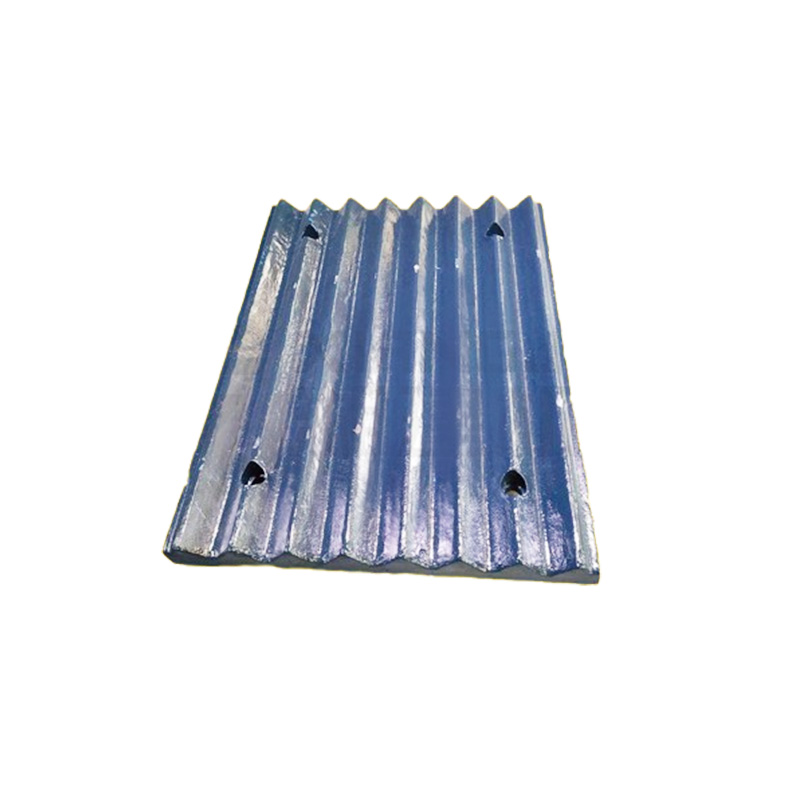

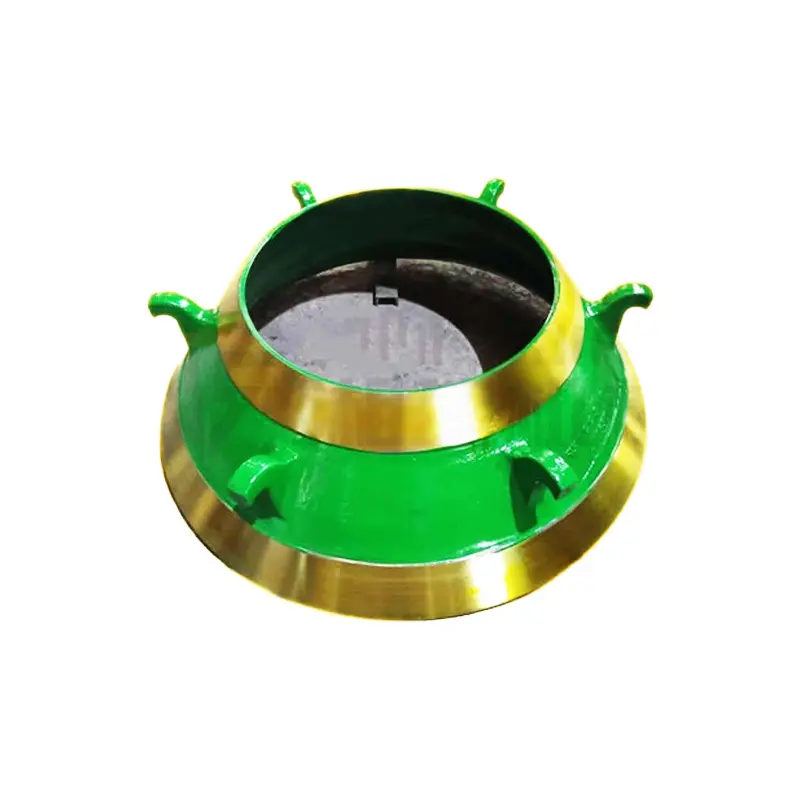

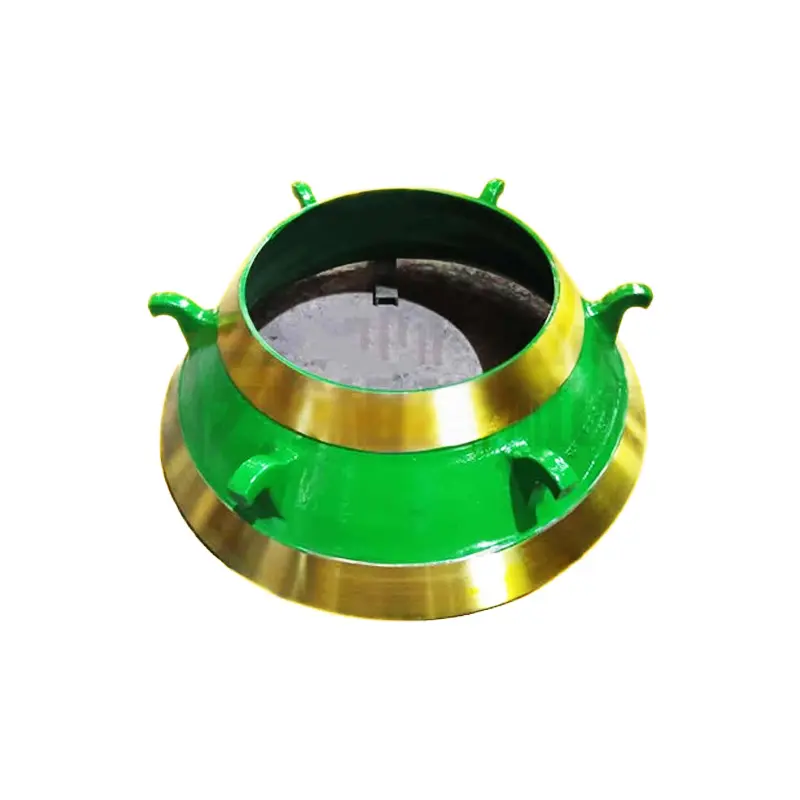

China Manufacturer cone crusher machine stone quarry movable cone crusher mantle concave

Working principle

The cone crusher moves in a swiveling motion under the driving action of the eccentric sleeve, driving the crushing wall to squeeze and grind the material between the mortar wall. According to the lamination theory, the material is subjected to forces in multiple directions, crushed and polished according to its own texture, forming stable stone particles. The material that meets the discharge requirements falls from the swing gap of the crushing wall, and the rest of the material continues to be crushed until the requirements are met.

The structure of the cone crusher includes a motor, a pulley or a coupling, a transmission shaft, a cone, etc. The motor drives the eccentric sleeve to rotate through the bevel gear, so that the crushing cone moves in a swiveling motion. The connection between the support sleeve and the frame is pressed by a spring. When an unbreakable object such as a metal block falls into the crusher, the spring is compressed and deformed, and foreign matter is discharged to prevent damage to the machine.

The application field of the cone crusher is very wide, and it is suitable for raw material crushing in industries such as metallurgy, construction, road construction, chemistry and silicate. It has a large crushing ratio, high efficiency, low energy consumption, and uniform product particle size. It is suitable for medium and fine crushing of various ores and rocks.

Product display

Main Features

1) Quality: 100% original factory standard, which is the most important reason why we can get so many customers all over the world.

2) Wide range of products: We provide a full range of common parts for these crusher brands.

3) High-quality materials: original, standard materials of parts.

4)Wide range of types: jaw crusher, cone crusher, horizontal shaft impact crusher, vertical shaft impact crusher, etc.

Both production capacity and efficiency are improved

The structure with the main shaft fixed and the eccentric sleeve rotating around the main shaft can withstand greater crushing power. Reasonable eccentricity, cavity type and motion parameters are matched to greatly improve production capacity and work efficiency.

Adopting layer compression crushing mechanism

The design adopts the layer compression crushing principle, so that crushing occurs between materials, with high crushing efficiency and excellent particle shape. It is a partner for producing high-quality aggregates. Fully automatic intelligent control is realized.

The electrical system adopts Siemens PLC and touch screen control system, ABB low-voltage control components, Siemens high-voltage motor; dual lubricating oil pumps, dual electric heaters, dual air coolers, and fully automatic intelligent control is realized.

Enhanced control system function

Adopting visual sensor values, visual freely configurable alarm solutions, and more flexible Internet measurement and control docking solutions.

Stable and intelligent operation capability

Convenient operation and maintenance, adding automation functions such as lubrication return oil flow monitoring, horizontal shaft speed monitoring, vibration monitoring, and automatic feeding control, extending the service life of the equipment, and making the crushing system have more stable and intelligent operation capabilities.

The working principle of cone crusher is that the moving cone is driven by the eccentric shaft through the motor to make the moving cone do eccentric rotation on the inner surface of the fixed cone, sometimes close to the fixed cone, sometimes away from the fixed cone. When the surface of the moving cone is close to the inner surface of the fixed cone, the ore is crushed by squeezing, bending and grinding; when the moving cone leaves, the crushed ore is discharged from the discharge port at the bottom of the cone, and the ore above falls down and continues to be crushed.