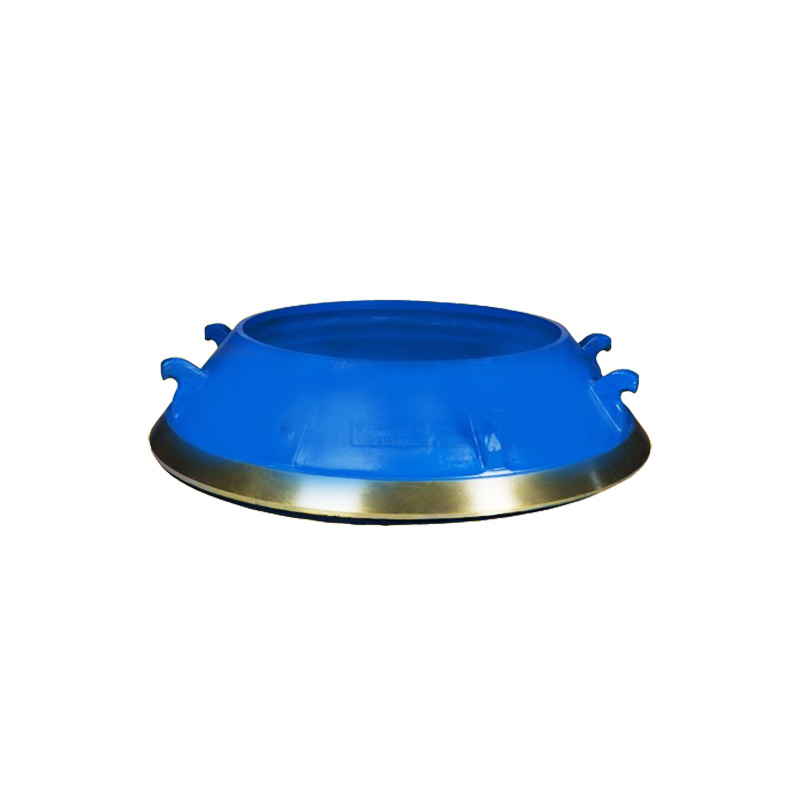

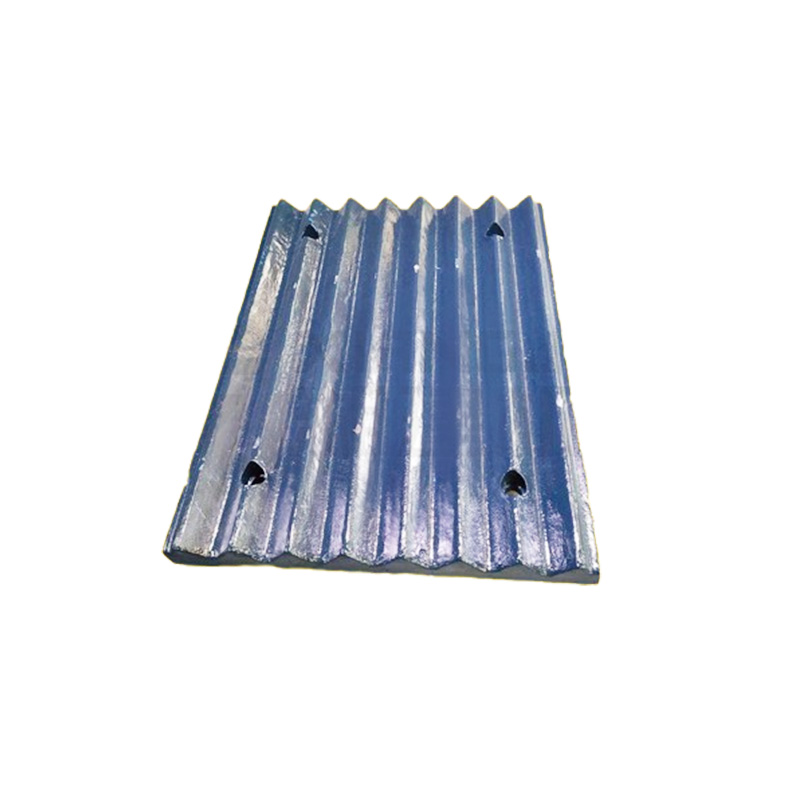

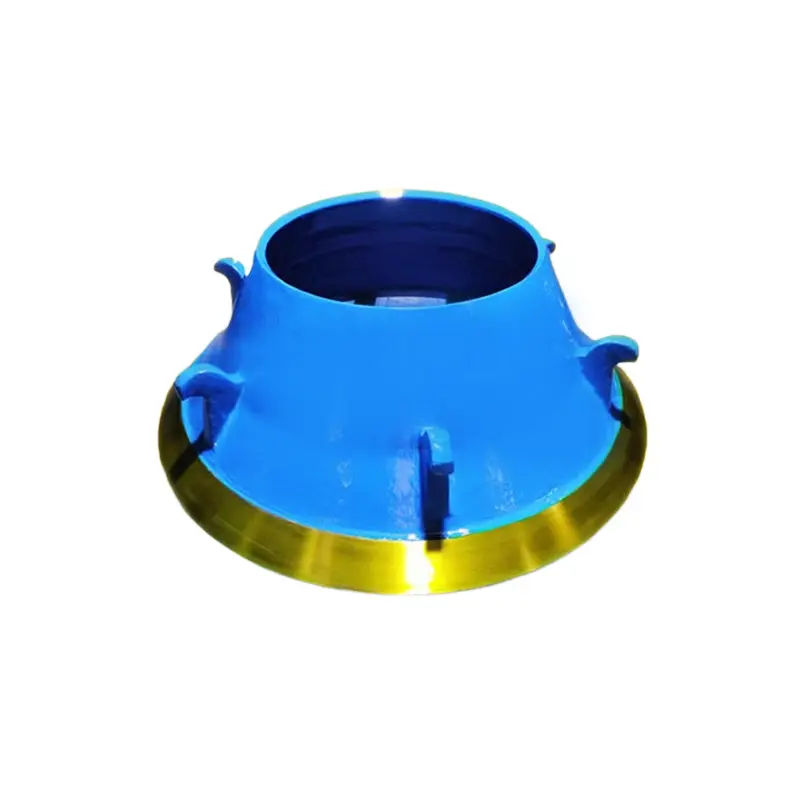

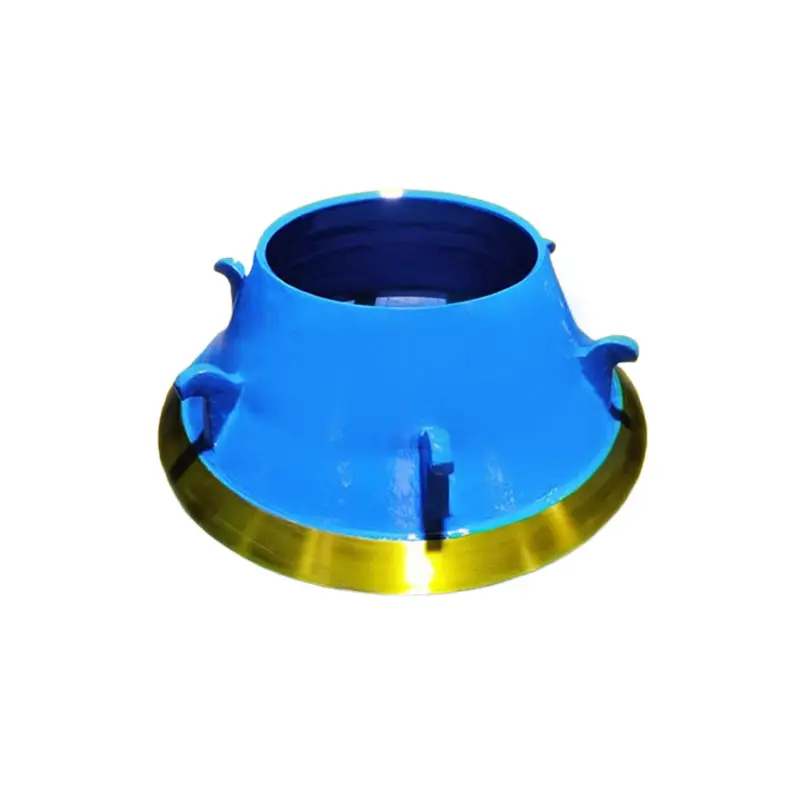

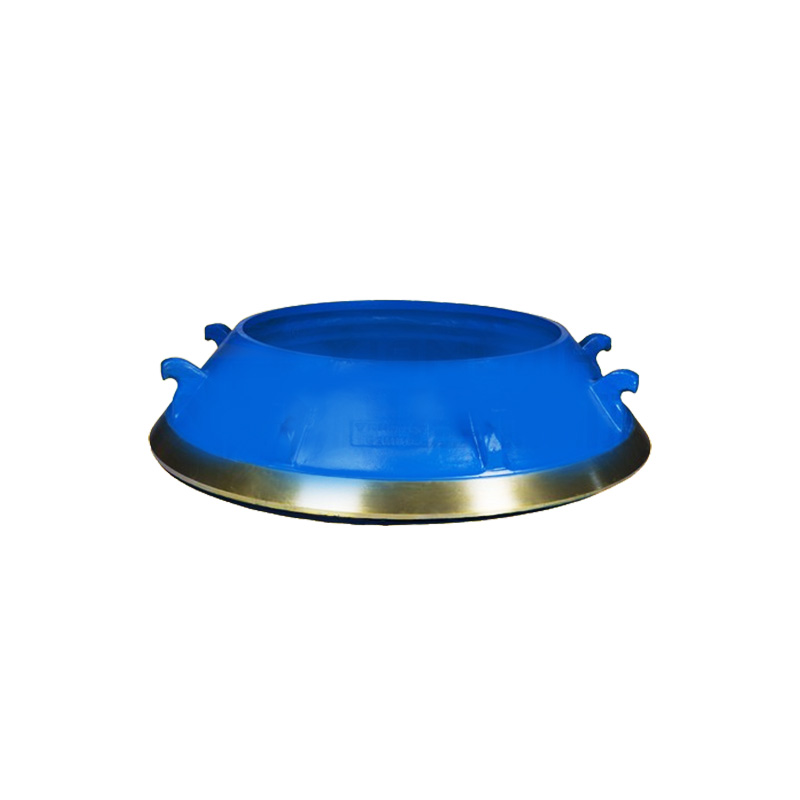

Bowl liner rock cone crusher parts hydraulic spring type cone crusher wear parts concave and mantle

Product introduction

The mantle concave is connected by casting zinc alloy. Its firmness should be checked after the cone crusher has been running for a period of time. The connection between the mortar wall and the adjustment ring is fixed by U-shaped fixing screws. Zinc alloy is cast between the mortar wall and the adjustment ring to make them tightly combined.

The mantle can be replaced on site. Unscrew the adjusting screw sleeve installed on the upper frame (note that it should be rotated counterclockwise), remove the upper chamber hopper assembly, lift the adjusting screw sleeve with a lifting device, remove the adjusting screw sleeve support plate bolts, and then remove the mortar wall for replacement. When assembling, clean the outer surface, apply butter on the thread surface of the adjusting screw sleeve, and install it in reverse order.

Cone crusher, also known as cone crusher (cone crusher), is a machine equipment, divided into three types: coarse crushing cone crusher, medium crushing cone crusher and fine crushing cone crusher.

Product display

Use

PYY series single cylinder hydraulic cone crusher is suitable for large and medium-sized sandstone and ore processing enterprises, for secondary, tertiary or quaternary crushing of ore, rock or rock-based materials. Wide range of applications: It can crush relatively hard rocks. The same main machine can obtain a variety of cavity types by replacing the liner, so as to adapt to various applications. The medium crushing type has a stable and large feed port, which is used for secondary crushing (even coarse crushing) of materials.

Working principle

The crushing process is completed by the eccentrically rotating crushing wall and mortar wall driven by the eccentric sleeve. The material enters the crushing wall through the upper feed hopper, is discharged from the lower part after crushing, and is collected and discharged by the inlet and outlet hoppers. It has the advantages of high output, low use cost, exquisite structure, simple operation, less maintenance, wide application range and high utilization rate.

Product Features

1. Wide range of applications

It can crush relatively hard rocks. The same main machine can obtain multiple cavity types by replacing the liner, so as to adapt to various applications. The medium crushing type has a stable and large feed port, which is used for secondary crushing (even coarse crushing) of materials.

2. Good product particle shape

The optimized combination of crushing frequency and eccentricity. And lamination crushing, so that the crushed material of the discharge port size maintains a good product particle shape.

3. Structural upgrade, higher safety

The transmission parts use imported bearings with longer life, positive pressure dust removal to ensure the cleanliness of the hydraulic system, and the thin oil lubrication system can achieve double protection for the bearings; effectively reduce the failure rate and maintenance costs.

4. Lower production cost

The optimized liner design makes the unit steel consumption lower; lamination crushing and full feeding make the equipment operation rate higher.

5. Simple operation and maintenance

The discharge port can be adjusted steplessly by hydraulic pressure with just button control, and it can be carried out during the production process, making the operation more intuitive. After fine processing, the wear parts do not require fillers during assembly.

6. High degree of automation

The PYY series cone crusher adopts a PLC control system, which can easily operate and control the crusher and reduce labor costs.