In the world of mining machinery, the efficiency and durability of equipment play a crucial role in determining operational success. Among the various components that significantly impact performance, the Mining Machinery Jaw Plate stands out due to its fundamental role in the crushing process. These plates are essential for breaking down materials, and understanding their design, materials, and functionality can be a game-changer for operators aiming to maximize their equipment's potential. This blog will delve into a comparison of different types of Mining Machinery Jaw Plates, exploring their unique features, advantages, and disadvantages. By illuminating the secrets behind these vital components, we aim to equip professionals in the mining industry with the knowledge needed to make informed decisions and enhance their operational efficiency.

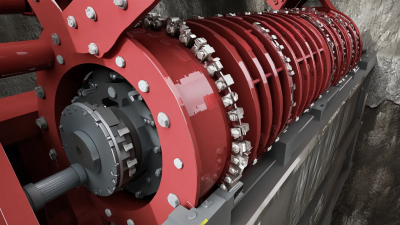

When it comes to mining machinery, understanding the different types of jaw plates is crucial for optimizing performance and prolonging equipment life. Jaw plates are vital components of jaw crushers, providing the necessary surface for breaking down rocks and ores. There are various materials and designs used in jaw plates, which can affect their durability and efficiency. Common types include fixed and swung jaw plates, each playing a unique role in the crushing process.

Choosing the right jaw plate material is essential for maximizing performance. High manganese steel jaw plates are popular for their excellent wear resistance and ability to withstand heavy crushing. For applications involving more abrasive materials, consider using jaw plates made from alloy steel, which can provide longer lifespan and better fracture resistance.

Tip: Regularly inspect your jaw plates for signs of wear or damage. Replacing worn jaw plates promptly can prevent excessive strain on machinery and maintain efficient operation. Moreover, keep an eye on the type of materials being crushed; selecting specific jaw plates based on material type can significantly impact the overall effectiveness of the mining process.

Understanding the material science behind jaw plate durability and performance is critical for optimizing mining machinery. Jaw plates, which are essential components of crushers, are subject to extreme wear due to their constant interaction with abrasive materials. Studies indicate that the choice of materials significantly influences the lifespan and functionality of these components. For instance, high manganese steel, often used for its excellent wear resistance and work-hardening properties, can increase jaw plate life by up to 50% compared to lower-grade materials.

Moreover, advancements in metallurgical processes have led to the development of composite jaw plates that integrate various alloying elements. Reports from the International Journal of Mining Science and Technology reveal that introducing elements like chromium can enhance toughness and improve impact resistance, allowing jaw plates to withstand harsher operating conditions. The combination of rigorous testing and tailored material composition is crucial, with some modern jaw plates achieving a wear resistance of over 800 Brinell hardness, making them ideal for heavy-duty applications in mining operations.

The design of jaw plates plays a critical role in optimizing crushing efficiency within the mining industry. According to a report published by the International Journal of Minerals Engineering, the performance of jaw crushers can be significantly influenced by the geometry and material properties of the jaw plates. For instance, a study revealed that a 10% increase in the surface area of jaw plates can lead to a 15% enhancement in throughput and a reduction in energy consumption by approximately 7%.

Moreover, advancements in materials technology have allowed manufacturers to produce jaw plates with superior wear resistance and strength. The use of high manganese steel, for example, has been shown to improve the longevity of jaw plates, resulting in lower replacement rates and reduced operational costs. Industry data indicates that modern jaw crushers with optimized jaw plate designs can achieve a crushing ratio exceeding 6:1, thus enhancing productivity while maintaining energy efficiency. As mining operations continue to focus on maximizing output and minimizing costs, the importance of effective jaw plate design cannot be overstated.

The replacement cycles of jaw plates in mining operations are significantly influenced by various economic factors. One of the primary considerations is the cost of raw materials and the fluctuating prices of metals. Higher market prices of ores can justify more frequent replacements, as companies aim to maximize productivity and maintain operational efficiency. Conversely, during periods of lower commodity prices, companies may opt to extend the life of their jaw plates, hoping to reduce operational costs until market conditions improve.

Additionally, the financial health of a mining operation directly impacts its maintenance scheduling. Firms facing budget constraints may delay necessary replacements, leading to increased wear and tear and potentially costing more in the long run. Conversely, well-capitalized operations might invest in high-quality jaw plates that offer better durability and performance, understanding that the initial expense can lead to significant savings and enhanced productivity over time. By carefully assessing these economic factors, mining companies can make informed decisions that balance cost with operational efficiency.

When it comes to mining machinery, jaw plates play a crucial role in the efficiency and productivity of operations. A statistical analysis of jaw plate wear rates across leading mining equipment brands reveals significant insights into their performance and longevity. By understanding these wear rates, operators can make informed choices about which equipment to invest in, ultimately enhancing their operational efficiencies.

**Tip 1:** Regularly monitor the wear rates of jaw plates used in your operations. Keeping detailed records can help identify trends and forecast maintenance needs, reducing unexpected downtime.

Different brands exhibit varying wear patterns influenced by factors such as material composition and design. This comparative analysis aids in selecting jaw plates that not only offer durability but are also cost-effective over time.

**Tip 2:** Consult with manufacturers to understand the specific wear characteristics of their jaw plates. This information can guide your procurement decisions, ensuring you choose the most suitable options for your specific mining conditions.

| Mining Equipment Type | Average Wear Rate (mm/month) | Material Type | Typical Lifespan (months) | Recommended Replacement Interval (months) |

|---|---|---|---|---|

| Excavator | 2.5 | High Manganese Steel | 12 | 10 |

| Crusher | 3.2 | Alloy Steel | 8 | 6 |

| Grizzly Feeder | 1.8 | Wear Resistant Steel | 14 | 12 |

| Jaw Crusher | 4.0 | High Manganese Steel | 10 | 8 |

| Screening Equipment | 2.0 | Carbon Steel | 16 | 14 |