Maintaining the Stone Crusher Moving Jaw is crucial for optimal performance. A well-maintained moving jaw ensures efficient crushing and reduces downtime. This component bears significant stress during operations, even with proper care. Failure to address its upkeep can lead to costly repairs and lost productivity.

Regular inspections are vital. Look for signs of wear, such as cracks or uneven surfaces. A worn moving jaw can compromise the entire system's efficiency. It’s important to establish a routine that addresses these issues before they escalate. Simple actions can greatly extend the lifespan of your equipment.

Lubrication is another key factor. Without proper grease, friction increases, leading to faster wear. Remember to use the right type and amount of lubricant. Overlooking this step can result in premature failure. Each component of the stone crusher must be considered to maintain overall operational success. Engaging in regular maintenance is not merely a recommendation; it's essential for longevity and performance.

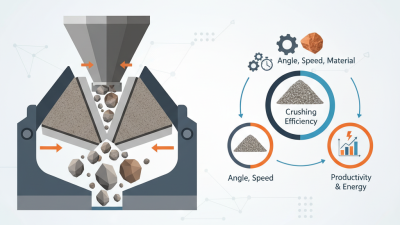

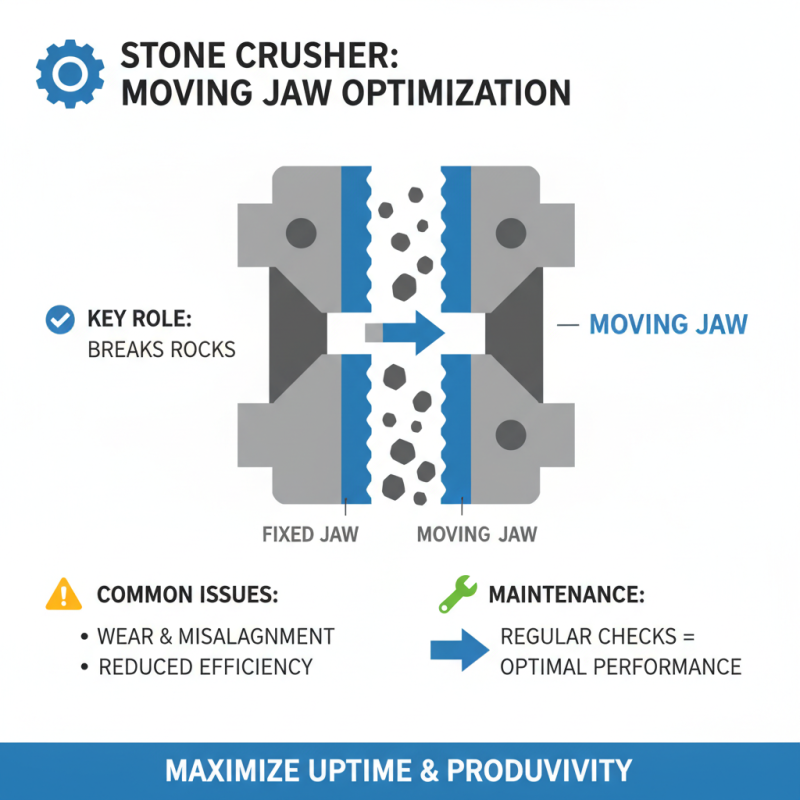

The moving jaw is a crucial component of stone crushers. It plays a vital role in the crushing process by applying force to break down rocks. With consistent operation, the moving jaw can wear out or become misaligned. This can lead to reduced efficiency and increased maintenance costs. Regularly checking the moving jaw ensures optimal performance.

Tips for maintaining your moving jaw include frequent inspections and lubrication. Keep the jaw and its components free of debris. Any buildup can cause wear or misalignment, negatively impacting the crushing process. Ensure that the moving jaw's alignment is correct. Misalignment can lead to uneven wear and potential failure.

Another key point is to monitor the jaw's wear pattern. Uneven wear indicates problems that need addressing. Consider using wear indicators to track the condition of the moving jaw. Don't overlook the importance of proper feeding. Overloading the machine can stress the moving jaw and create issues. Regular attention to these details can prolong the life of your stone crusher.

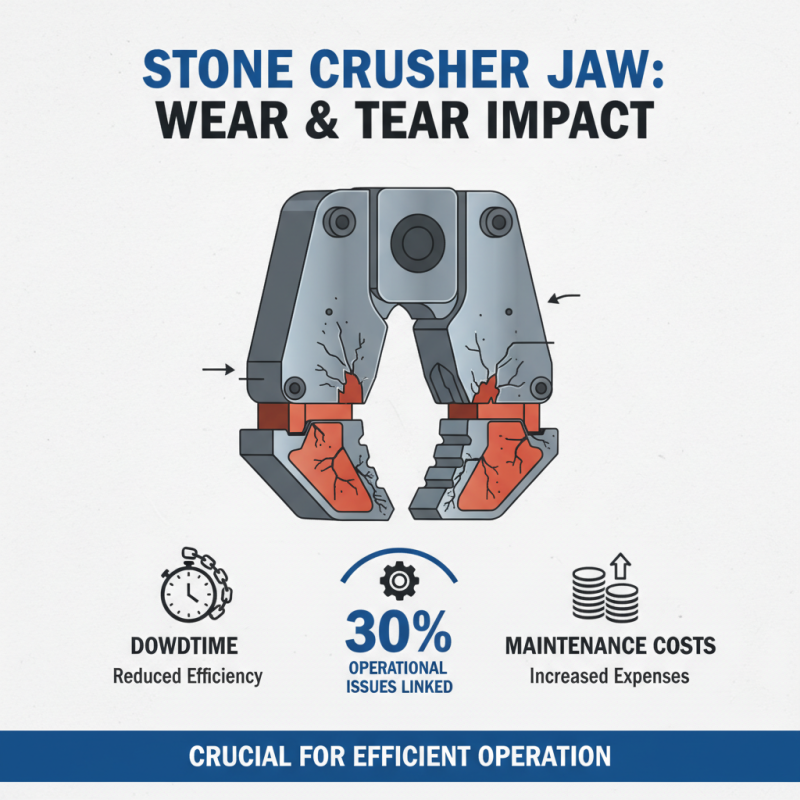

The moving jaw of a stone crusher is crucial for efficient operation. However, it often faces significant wear and tear. This wear can lead to unwanted downtimes and increased maintenance costs. According to industry reports, up to 30% of operational issues are linked to the moving jaw.

Common causes include misalignment and excessive load. When the jaw is misaligned, it can create uneven wear. This results in reduced crushing efficiency. A survey indicated that more than 40% of operators noted alignment issues as a primary concern. Additionally, overloading the jaw can cause fractures. A study showed that nearly 25% of moving jaws fail due to overload scenarios.

Regular inspections are essential. Look for cracks and unusual wear patterns. Implementing a strict maintenance schedule can help reduce these issues. Inadequate lubrication is another factor. It can lead to increased friction and accelerated wear. It's vital to monitor lubrication levels consistently to prevent premature failure. Regularly addressing these areas can vastly improve the lifespan of the moving jaw.

Maintenance of the moving jaw in a stone crusher is crucial for efficiency. Regular checks can prevent unexpected failures. Industry reports indicate that neglecting maintenance can lead to a 30% reduction in operational lifespan. This statistic highlights the need for proactive measures.

Daily inspections are key to identifying wear and tear. Look for cracks or unusual vibrations. These signs can indicate more serious issues. Lubrication is essential. The right lubricant minimizes friction and wear. Using subpar products may lead to premature failure. Remember, a well-lubricated system can reduce energy consumption by up to 15%.

Additionally, consider the importance of timely replacements. Changing worn-out parts can prevent larger problems. Many operators fail to schedule these replacements adequately. A study revealed that 40% of breakdowns are due to overlooked maintenance. Keeping a maintenance log can help track these changes systematically. It's crucial to acknowledge mistakes and learn from them, ensuring the moving jaw operates smoothly for years to come.

Regular inspection techniques are crucial for ensuring the longevity of stone crusher moving jaws. One effective approach is to conduct visual inspections at regular intervals. Observing wear patterns can reveal underlying issues. Cracks or unusual wear can indicate misalignment or improper lubrication. Keeping a log of these findings helps track changes over time.

Another inspection method involves measuring the wear parts. Studies indicate that measuring the gap between moving jaws can lead to significant production efficiency. Small gaps may reduce performance, while large gaps can be detrimental. A report from industry experts shows that proper measurement can increase operational efficiency by 15%.

Additionally, utilizing vibration analysis can provide insights into the health of the moving jaw. Unusual vibration patterns often signal mechanical issues. Ideally, regular monitoring should become a habit. Yet, it’s not uncommon to overlook inspections due to busy schedules. This can lead to unexpected failures and costly downtime. Investing time in these inspections pays off in the long run, ensuring consistent performance.

| Inspection Technique | Frequency | Purpose | Notes |

|---|---|---|---|

| Visual Inspection | Daily | Identify visible wear and cracks | Look for any unusual signs of wear |

| Performance Monitoring | Weekly | Assess operational efficiency | Check for variations in output |

| Lubrication Check | Monthly | Ensure all moving parts are lubricated | Use recommended lubricants only |

| Alignment Inspection | Quarterly | Verify correct positioning of components | Misalignment can cause excess wear |

| Wear Part Replacement | As needed | Maintain effective crushing performance | Monitor wear regularly to anticipate replacements |

Maintaining a stone crusher's moving jaw is crucial for optimal performance. Regularly inspecting for signs of damage can save time and resources. Look for cracks or excessive wear on the jaw's surface. Even minor fractures can lead to bigger problems. If you notice unusual noises during operation, that's a red flag. The moving jaw may not function correctly, impacting productivity.

Another indication of wear is inconsistent material output. If the crushed stones vary in size too much, the moving jaw may be losing its effectiveness. Additionally, monitor the alignment. Misalignment might cause premature wear. Inspect the jaw for any signs of distortion. When these issues arise, consider replacement.

Deciding when to replace the moving jaw can be tricky. A good rule is to evaluate the wear every few months. If the wear exceeds 30% of the original thickness, it's time for a change. Waiting too long can result in costly repairs. Keep an eye on the health of your equipment. Early detection can prevent larger issues down the line.