In the ever-evolving field of mining and construction, the role of fixed jaw plates is critical. As one of the essential components in crushing machinery, their efficiency directly influences production rates. According to industry expert John Smith, a renowned engineer in the sector, “The quality of fixed jaw plates can make or break a crushing operation.”

Today, several fixed jaw plate manufacturers are leading the pack. They are focused not only on durability but also on innovative designs that enhance performance. Companies like X-Tech and Crusher Co. have made a name for themselves by prioritizing quality and precision. However, the market is not without its challenges. Some manufacturers struggle to maintain consistency, leading to concerns among buyers.

Additionally, as demand increases, manufacturers must adapt to changing technologies. This can sometimes lead to shortcuts, raising questions about the long-term reliability of their products. It's crucial for stakeholders to reflect on these issues. The landscape is competitive, but it also calls for quality assurance and continuous improvement among fixed jaw plate manufacturers.

In the world of heavy machinery, fixed jaw plates are essential for optimal performance. These components play a vital role in crushing and breaking down materials. Selecting a top manufacturer can significantly impact the quality and durability of your machinery. Many companies are pushing boundaries, yet not all provide consistent quality. This inconsistency can lead to unexpected downtime and increased costs.

Leading manufacturers focus on using premium materials. They understand that the right alloy can make a difference in performance. Casting processes vary widely, and some techniques yield better results than others. A few are even experimenting with innovative designs. However, these advancements might not always translate to immediate benefits. Companies must carefully evaluate the real-world implications of new designs before adopting them widely.

Customer feedback is crucial in this industry. Manufacturers must listen to what users say about wear and tear. Some designs might look promising on paper, but fail in practice. Constant communication with end-users ensures improvements are practical and effective. Striking a balance between innovation and reliability remains a challenge for many. The journey to optimizing fixed jaw plates is ongoing, with much room for learning and refinement.

Fixed jaw plates are essential components in several heavy machinery, especially in the mining and construction sectors. High-quality plates are critical for optimizing performance and reducing downtime. One key feature of these plates is their material composition. Most premium plates use high manganese steel, which provides better wear resistance and durability.

Wear resistance alone isn’t enough. The design of the jaw plate plays a significant role in its effectiveness. A well-engineered fixed jaw plate should have the proper geometry to maximize crushing efficiency. Studies show that companies using advanced design features experience a 15-20% increase in productivity. This impact emphasizes the importance of investing in quality manufacturing processes and innovative technology.

It’s also important to consider the fit and compatibility with existing machinery. Misaligned or inadequately fitted plates lead to increased wear and tear. A study revealed that nearly 30% of maintenance issues stem from poor installation of fixed jaw plates. Regular assessments and adjustments can mitigate these issues. While many manufacturers offer high-quality options, the selection process can be challenging. Balancing cost and performance often requires careful consideration.

When exploring the landscape of fixed jaw plate manufacturers, several factors come into play. Material quality is crucial; it directly impacts durability. Leading manufacturers often use advanced alloys to enhance strength. Their designs also focus on reducing wear, which is a common pain point for many users. However, not all manufacturers prioritize these elements equally. This inconsistency can lead to variable performance across different brands.

Another aspect to consider is the manufacturing process itself. Some companies emphasize precision engineering, ensuring that every piece fits perfectly. Others may cut corners, yielding subpar products. Users have reported mixed experiences with these variations. This highlights the necessity for thorough research before making a purchase. Moreover, customer service varies widely among manufacturers. Prompt support can make a significant difference, especially when maintenance issues arise.

Price is always an important consideration. While some users lean toward more economical options, the long-term costs may outweigh initial savings. Investing in quality often results in fewer replacements and repairs. Yet, it’s tempting to opt for lower prices when budgets are tight. Balancing affordability and quality remains a challenge for many in the industry.

| Manufacturer | Material Type | Hardness | Weight (kg) | Warranty Period | Customer Rating |

|---|---|---|---|---|---|

| Manufacturer A | High Carbon Steel | HRC 48-52 | 350 | 12 Months | 4.5/5 |

| Manufacturer B | Manganese Steel | HRC 50-55 | 400 | 18 Months | 4.7/5 |

| Manufacturer C | Cast Iron | HRC 45-50 | 300 | 10 Months | 4.2/5 |

| Manufacturer D | Composite Material | HRC 46-51 | 250 | 24 Months | 4.8/5 |

| Manufacturer E | Alloy Steel | HRC 52-55 | 380 | 15 Months | 4.6/5 |

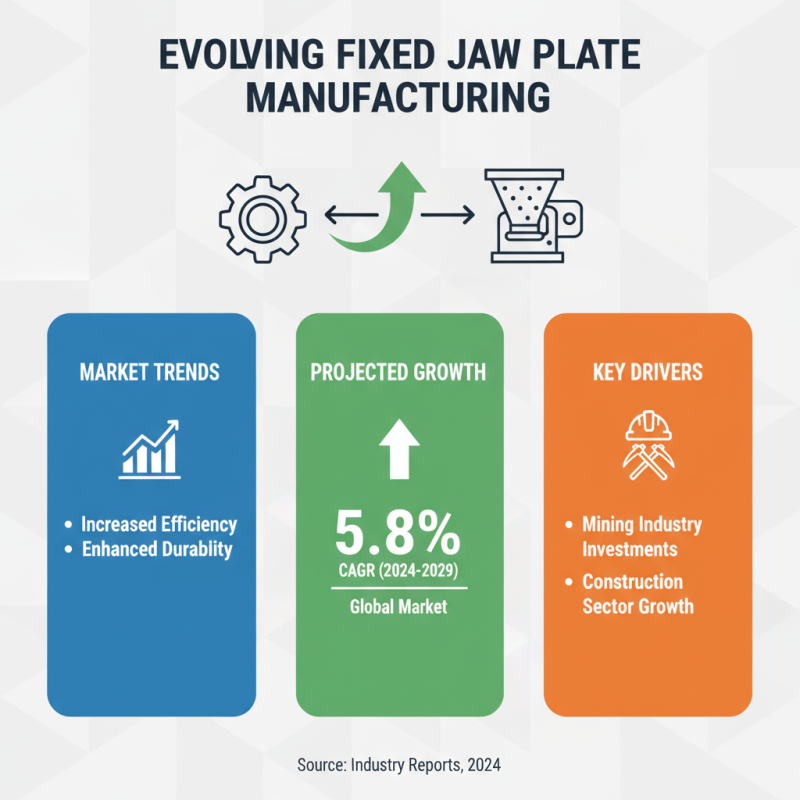

The manufacturing of fixed jaw plates is evolving rapidly. Market trends are shifting due to increased demand for efficiency and durability. Recent reports indicate a projected growth rate of 5.8% in the global market during the next five years. This trend is driven by rising investments in mining and construction industries.

Manufacturers are focusing on advanced materials. High-quality steel alloys are now preferred. This change improves the lifespan of fixed jaw plates. However, it's crucial to manage costs effectively. Many manufacturers struggle with balancing quality and expenses. The ongoing push for sustainability complicates this challenge.

Tips: Invest in research to understand material performance. Regularly update production techniques to incorporate new technologies. Staying informed on market dynamics fosters adaptability. Companies need to refine strategies to meet changing customer expectations. This reflection on past practices can lead to better decision-making in future production.

The design and materials of fixed jaw plates are evolving rapidly. Innovations are crucial for efficiency and durability in crushing equipment. New materials like high-strength alloys are increasingly used. These innovations lead to longer wear life and better performance.

Tips: Consider how material choice affects wear resistance. Sometimes, a cheaper option may lead to higher replacement costs. Analyze your specific application needs to avoid costly mistakes.

The geometry of fixed jaw plates is also improving. Designs are more ergonomic, enhancing the crushing process. Some manufacturers focus on optimizing the surface patterns for better material flow. This approach can reduce energy consumption.

Tips: Regularly inspect your equipment for signs of wear. Proper maintenance can extend the life of your fixed jaw plates. Be aware of how design changes can impact your operations.