Understanding cone crusher parts is vital for efficient operations in various industries. These crucial components play significant roles in the crusher's performance. From liners to mantles, each part affects productivity and longevity.

Cone crusher parts are designed to withstand high pressures and abrasive materials. Proper maintenance is essential for their optimal functioning. However, users often overlook the need for regular checks on wear parts. This negligence can lead to decreased output and increased costs.

When you understand these components better, you can make informed decisions. Investing in quality cone crusher parts can improve reliability. Awareness of their significance can prevent common pitfalls. Ultimately, knowledge is a key advantage in maximizing crusher efficiency.

Cone crushers are vital for mining, quarrying, and recycling industries. Understanding the essential parts can boost performance. One key component is the mantle. It crushes rocks against the concave. A worn mantle can lead to less efficient crushing.

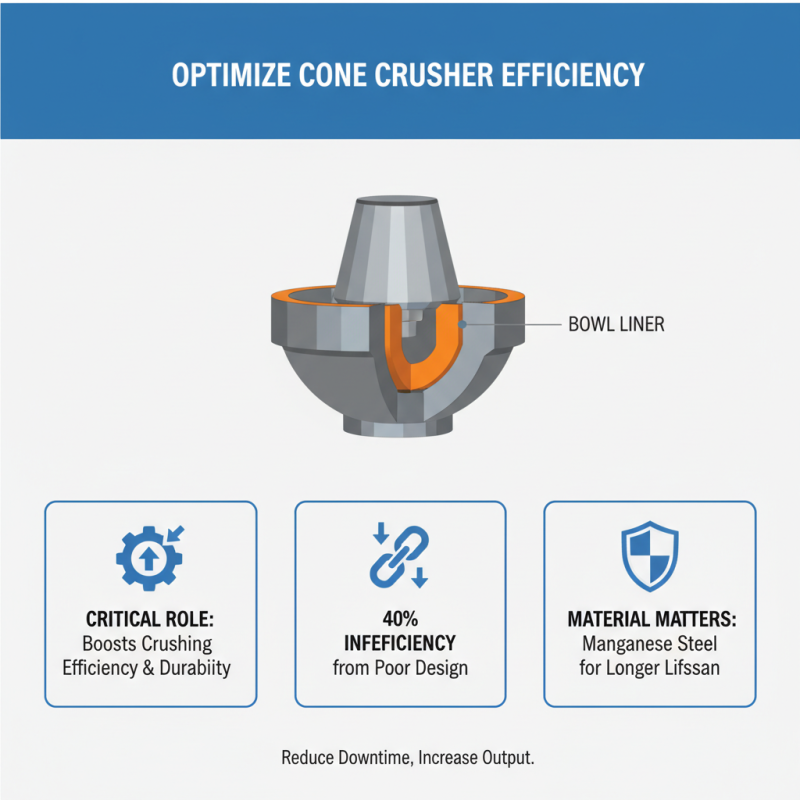

Another important part is the bowl liner. It protects the body from wear and tear. Regularly checking both the mantle and bowl liner helps maintain optimal crushing. The adjusting ring allows for precise adjustments. It affects how close the mantle gets to the bowl liner. If it’s off, it can lead to uneven product size.

Hydraulic systems play a huge role, too. They control the crusher’s settings and provide safety during operation. Regular maintenance of hydraulic cylinders is crucial. Ignoring it can lead to costly failures. Lastly, the frame supports all components. A weakened frame raises concerns for stability and operation. Regular inspections and repairs are vital for longevity.

Understanding these parts will help you operate your machine more effectively.

The mantle in a cone crusher plays a pivotal role in its functionality. It is the main component that crushes materials. The mantle moves in a circular pattern, compressing the material against the concave surface. This action drives the crushing process forward, enabling efficient reduction in size.

Maintaining the mantle's integrity is crucial. Over time, wear occurs due to the constant abrasion from hard materials. Operators must monitor the mantle for signs of wear. Replacing a worn mantle prevents suboptimal crushing efficiency. Neglecting this could lead to increased machine stress and lower production rates.

The choice of material for the mantle also matters. It must balance toughness and wear resistance. Some materials perform well, while others do not. Analyzing the performance of different options can provide insights for better choices. Operators should reflect on their selections. Continuous improvement in this area can lead to enhanced productivity and equipment longevity.

| Part Name | Material | Role in Functionality | Typical Failure Modes |

|---|---|---|---|

| Mantle | Manganese Steel | Crushes rock material with the help of the concave. | Wearing down, cracking, or excessive wear. |

| Concave | Manganese Steel | Works with mantle to crush materials. | Chipping, deformation, and wear. |

| Bowl Liner | Manganese Steel | Provides another crushing surface. | Wear and cracking. |

| Spider Cap | Cast Steel | Supports the mantle and distributes the load. | Cracking or wear at joints. |

| Eccentric Shaft | Forged Steel | Enables cone movement for crushing. | Bending, breaking, or excessive wear. |

| Drive Shaft | Steel | Transmits power from the motor to the eccentric. | Failure due to overload or misalignment. |

| Hydraulic Cylinder | Steel | Provides automatic adjustment to the crushing gap. | Leakage or failure to adjust. |

| Dust Seal | Rubber | Prevents dust and debris from entering. | Wearing out or tearing. |

| Frame | Welded Steel | Provides structural support for all components. | Deformation or cracking due to stress. |

| Pinion Gear | Steel | Transfers power from motor to gear shaft. | Wearing or breaking due to wear and tear. |

The bowl liner plays a critical role in the overall efficiency and durability of a cone crusher. A well-designed bowl liner can significantly optimize the crushing process. Reports show that up to 40% of crushing inefficiencies stem from poor liner design. The material composition of the bowl liner also affects wear rates. High-quality manganese steel liners typically last longer, reducing the need for frequent replacements.

In real-world applications, operators often notice a drop in performance when the bowl liner is worn. This can lead to increased operational costs. One study found that maintaining an optimal gap between the bowl liner and the mantle can enhance production rates by 20%. Additionally, a misaligned bowl liner can cause uneven wear, leading to premature failure. Regular inspections are essential to address these issues early.

Investing in the right bowl liner not only boosts efficiency but also minimizes downtime. A proactive approach involves keeping track of liner wear patterns. Implementing a monitoring system can provide insights into when to replace or adjust the liners. Ultimately, understanding the importance of the bowl liner can lead to smarter management of resources and extended equipment life.

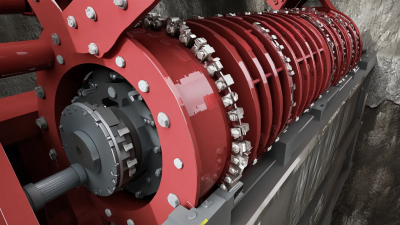

The shaft assembly is a critical component in cone crushers. It connects the drive mechanism to the crushing tools. A well-functioning shaft ensures consistent performance. Without it, efficiency drops significantly. This assembly bears substantial weight and stress during operation. Issues such as misalignment or wear can lead to catastrophic failures. Regular inspection of the shaft is essential.

Maintenance of the shaft assembly is often overlooked. Operators usually focus on more visible components. However, a neglected shaft can cause increased downtime. It's crucial to lubricate the shaft regularly. Proper lubrication minimizes friction and prolongs service life. Additionally, monitoring vibration levels can indicate potential problems early. This proactive approach saves time and resources.

Understanding the shaft assembly's function helps in operations. It transforms rotary motion into crushing force. This process requires precise engineering. Inadequate attention to this detail can result in poor output. Regular maintenance checks and proper handling are vital for long-term performance. Reflecting on these practices can lead to better insights into operational efficiency.

The drive system of a cone crusher plays a crucial role in its operational effectiveness. Efficient drive systems lead to better performance. According to a recent industry report, over 80% of production delays are linked to mechanical failures in these systems. These failures often arise from inadequate maintenance or suboptimal design choices.

Different types of drive systems, such as direct and belt-driven, impact power consumption and efficiency. Direct drive systems often provide a more compact design. They can reduce energy losses by up to 15% compared to belt-driven systems. However, they may involve higher upfront costs and require careful monitoring. Poorly aligned belts can lead to increased wear and tear.

Operational analytics indicate that proper training and awareness can mitigate many drive system issues. Implementing predictive maintenance strategies helps in identifying potential failures before they disrupt operations. Data shows that proactive maintenance can reduce downtime by up to 30%. These insights emphasize the need for a balanced approach to managing the drive system for optimal cone crusher performance.