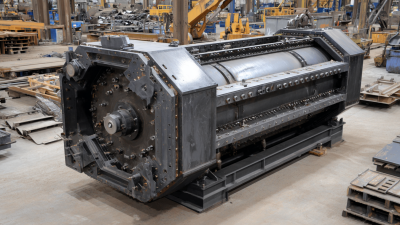

In the realm of manufacturing, optimizing the performance of critical components is essential for enhancing efficiency and product quality. One such pivotal part is the Moving Jaw, a key element in various machinery, particularly in jaw crushers and similar equipment. The performance of the Moving Jaw directly influences operational productivity, energy consumption, and overall equipment lifespan.

As manufacturers strive to enhance their processes and reduce costs, implementing strategies for optimizing Moving Jaw performance has become increasingly important. This blog will explore the seven best strategies for maximizing the effectiveness of the Moving Jaw, delving into the benefits of each approach and how they can lead to significant improvements in manufacturing operations. From material selection to design enhancements, understanding these strategies will empower manufacturers to achieve superior results in their production efforts.

When it comes to manufacturing moving jaws, selecting high-quality materials is crucial for ensuring optimal performance and longevity. The right materials can significantly impact factors such as durability, weight, and overall efficiency. High-strength alloys, for example, provide the necessary resilience to withstand the stresses of operation while minimizing wear and tear over time.

**Tip:** Always evaluate the mechanical properties of the materials you are considering, such as tensile strength and fatigue resistance. This will help you choose the right material that meets your operational demands.

Another important aspect is compatibility with manufacturing processes. Some materials may be more suitable for specific machining techniques, which can affect production costs and time. For instance, materials that are easier to weld or machine can lead to faster production cycles and reduced scrap rates.

**Tip:** Consider the full lifecycle of the material, including its availability and cost-effectiveness in the long run. An initial investment in a higher-quality material can result in lower maintenance and replacement costs over the lifespan of the moving jaw.

Enhancing the performance efficiency of moving jaws in manufacturing processes is crucial for optimizing productivity and reducing operational costs.

Advanced simulation techniques play a significant role in achieving this goal. According to a study by the International Journal of Advanced Manufacturing Technology,

simulation can improve production efficiency by up to 30% by enabling manufacturers to analyze and adjust mechanical systems before actual implementation.

This proactive approach minimizes downtime and material waste, leading to substantial cost savings.

Tip: Incorporating finite element analysis (FEA) during the design phase allows manufacturers to identify potential points of failure in jaw mechanisms.

By simulating various stress conditions, adjustments can be made to improve durability and performance reliability.

Furthermore, real-time simulations during the production process can help fine-tune jaw specifications, ensuring optimal results with minimal disruptions.

Moreover, computational fluid dynamics (CFD) can be utilized to enhance the cooling and lubrication systems of moving jaws.

As highlighted in a report by the Manufacturing Industry Report, effective fluid management can lead to a 20% increase in jaw performance due to reduced friction and wear.

Implementing CFD alongside advanced simulation techniques ensures a comprehensive approach to performance optimization.

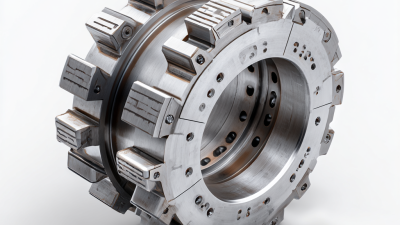

In the manufacturing industry, the longevity and performance of moving jaws are pivotal for ensuring operational efficiency and reducing maintenance costs. Precision engineering plays a critical role in minimizing wear and tear on these components. According to a report from the National Institute of Standards and Technology, effective machining and material selection can reduce the wear rate of jaws by up to 30%, significantly prolonging their lifespan and reliability. Techniques such as advanced surface treatments and the use of high-performance alloys have shown a marked decrease in friction and wear, directly impacting productivity levels.

In the manufacturing industry, the longevity and performance of moving jaws are pivotal for ensuring operational efficiency and reducing maintenance costs. Precision engineering plays a critical role in minimizing wear and tear on these components. According to a report from the National Institute of Standards and Technology, effective machining and material selection can reduce the wear rate of jaws by up to 30%, significantly prolonging their lifespan and reliability. Techniques such as advanced surface treatments and the use of high-performance alloys have shown a marked decrease in friction and wear, directly impacting productivity levels.

Moreover, integrating precision engineering methodologies like Computer Numerical Control (CNC) machining allows for tighter tolerances and higher-quality finishes on moving jaws. Research from the Society of Manufacturing Engineers indicates that implementing CNC systems can enhance part accuracy by 50%, leading to a marked reduction in misalignments and subsequent wear. This precision not only optimizes the mechanical performance of the jaws but also aids in maintaining their structural integrity under varying operational stresses, further reinforcing the importance of meticulous engineering practices in enhancing manufacturing outcomes.

The alignment of moving jaws plays a crucial role in manufacturing productivity, directly influencing cycle times, product quality, and overall operational efficiency. According to a report by the National Institute of Standards and Technology (NIST), misalignment in jaw configurations can lead to production inefficiencies of up to 15%. This inefficiency not only affects the throughput but also increases the wear and tear on machinery, leading to higher maintenance costs—which can be as much as 20% of a facility's operating expenses, as noted by the Manufacturing Maintenance Council.

Moreover, ensuring optimal jaw alignment can significantly enhance product consistency and reduce defects. A study published in the Journal of Manufacturing Science and Engineering found that aligning moving jaws to within 0.01 mm of the specified tolerance resulted in a 25% reduction in scrap rates. This level of precision is essential in sectors like aerospace and automotive manufacturing, where the cost of defects can lead to rework costs exceeding $1 million annually. Implementing rigorous alignment checks and adopting advanced alignment tools can thus not only streamline operations but also contribute to substantial cost savings and improved product reliability.

Implementing predictive maintenance strategies is crucial for enhancing the lifespan and reliability of moving jaws in manufacturing. By leveraging advanced technologies to anticipate potential failures, manufacturers can minimize downtime and reduce repair costs. This proactive approach not only extends the life of the equipment but also ensures consistent operational performance.

One effective tip for implementing predictive maintenance is to utilize IoT sensors to monitor the condition of moving jaws in real-time. These sensors can collect data on operational parameters such as temperature, vibration, and alignment. By analyzing this data, manufacturers can identify unusual patterns or anomalies that signal the need for maintenance before a major breakdown occurs.

Another strategy is to establish a regular maintenance schedule based on the insights gained from predictive analytics. This should include routine inspections, lubrication, and alignment adjustments as necessary. Creating a detailed maintenance log can help track the performance of the jaws and facilitate timely interventions, ensuring that each component operates at its best and preventing unexpected failures.