The efficiency and performance of a stone crusher heavily rely on its key components, one of the most critical being the Stone Crusher Moving Jaw. This integral part plays a pivotal role in the crushing operation, facilitating the size reduction of materials fed into the crusher. The moving jaw's design and mechanics directly influence the overall capability of the crusher; hence, a thorough understanding of its functionality and impact on performance is essential for optimizing operations in construction and mining industries.

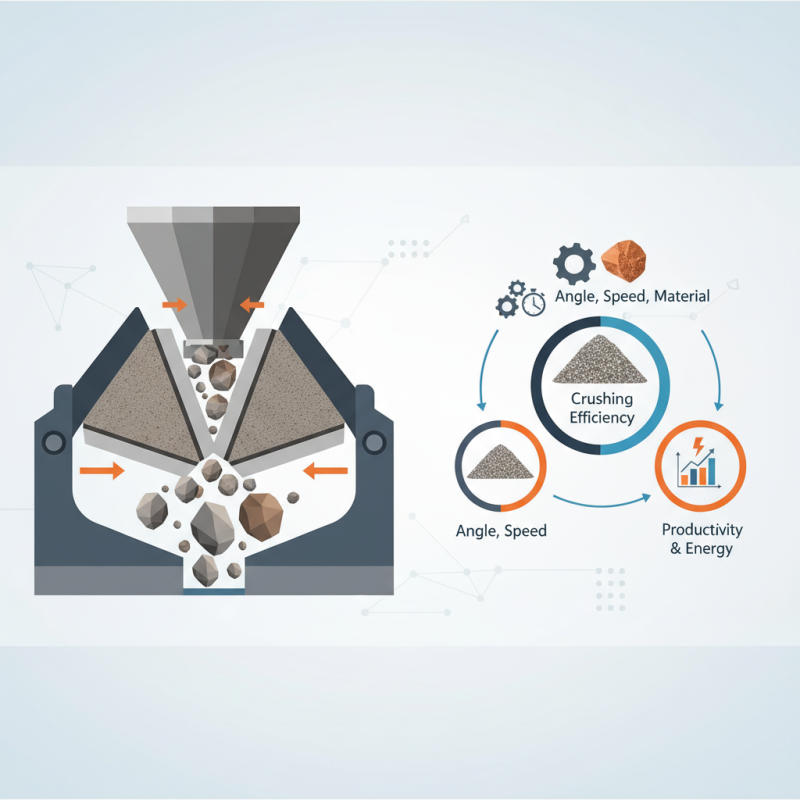

In essence, the Stone Crusher Moving Jaw operates through a reciprocating motion that compresses the material against a fixed jaw, breaking it down into smaller fragments. The efficiency of this process is determined by several factors, including the angle of the jaw, the speed of operation, and the material characteristics. As the industry evolves, innovations in moving jaw design are continuously being explored to enhance the crushing process, leading to improvements in productivity and energy consumption.

Understanding the Stone Crusher Moving Jaw is therefore crucial for professionals engaged in material processing. By focusing on the mechanics and performance implications of this component, operators can make informed decisions regarding maintenance, upgrades, and operational strategies, ultimately leading to improved output and reduced operational costs in their stone crushing endeavors.

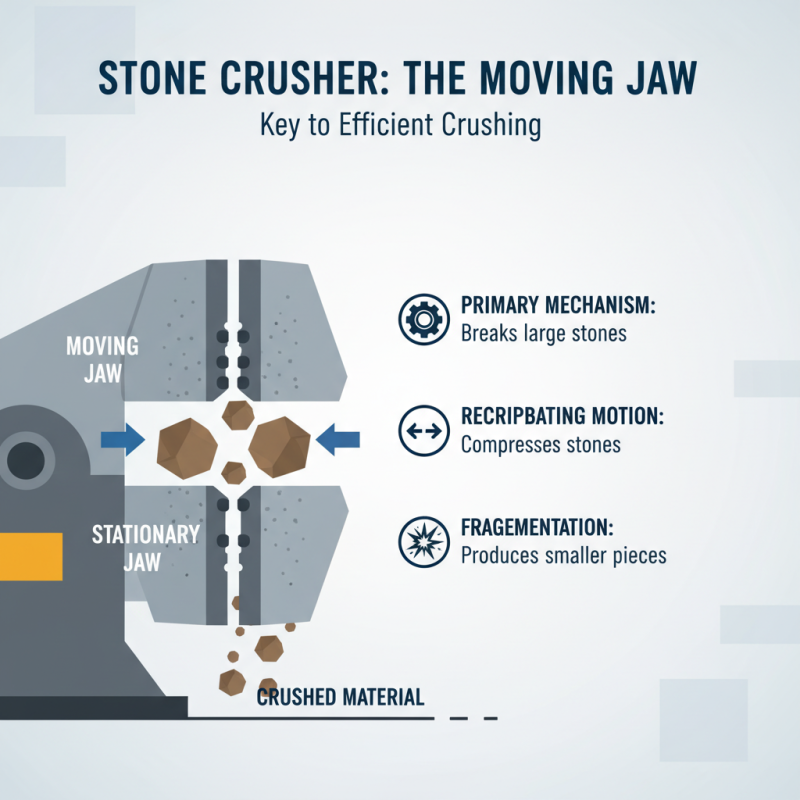

The moving jaw of a stone crusher is a critical component that plays a vital role in the crushing process. It is part of the primary mechanism that facilitates the breakdown of large stones into smaller, manageable pieces. The design and movement of the moving jaw contribute significantly to the efficiency of the crushing operation. As the moving jaw reciprocates, it creates a space for stones to enter and be compressed against the stationary jaw. This compression is what ultimately results in the fragmentation of the material.

The functioning of the moving jaw directly impacts the performance of the stone crusher. A well-designed moving jaw can enhance throughput, ensuring that the crusher operates at optimal levels. Furthermore, the angle at which the moving jaw pivots influences the size and shape of the crushed material, as well as the force applied during the crushing cycle. Different configurations can lead to variations in wear and tear, maintenance requirements, and overall productivity. Understanding the role of the moving jaw allows operators to optimize their equipment for better performance and longevity.

The stone crusher moving jaw assembly is a crucial component in the operation of a stone crusher. This assembly is primarily responsible for crushing the stones fed into the machine. It consists of several essential parts, including the moving jaw itself, a toggle plate, and a crank mechanism. The moving jaw is typically constructed from high-strength materials to withstand the pressure generated during crushing. The toggle plate serves as a pivot point, allowing the jaw to swing and create the necessary force to break down the material.

In addition to these core components, the moving jaw assembly may also feature various enhancements such as wear plates and hydraulic systems. Wear plates protect the surfaces of the moving jaw from excessive wear and tear, prolonging the assembly's lifespan and maintaining efficiency. The integration of hydraulic systems can improve the control over the crushing process by enabling adjustments in the jaw's movement and pressure applied during operation. All these components work in unison to ensure that the stone crusher operates at optimal performance, emphasizing the significance of a well-engineered moving jaw assembly in the overall functionality of the machinery.

| Component | Function | Impact on Performance | Material Used |

|---|---|---|---|

| Moving Jaw | Crushes the stone by squeezing it | Crucial for the primary crushing efficiency | High-strength manganese steel |

| Toggle Plate | Transmits the power to the moving jaw | Affects the crushing stroke and angle | Cast iron or steel |

| Jaw Plate | Forms the crushing surface | Directly influences the size of crushed products | Wear-resistant material |

| Bearing | Supports the moving jaw assembly | Reduces friction and ensures smooth operation | High-quality steel |

| Frame | Houses the entire assembly | Ensures stability during operation | Welded steel structure |

The moving jaw plays a crucial role in the stone crushing process, significantly impacting the overall performance of a crusher. Its primary functionality involves generating compressive force to fragment rock materials, which ultimately reduces them to smaller, manageable sizes. According to a report by the National Stone, Sand & Gravel Association, the efficiency of a stone crusher can be enhanced by optimizing the dynamics of the moving jaw, which directly affects throughput and energy consumption. A well-designed moving jaw can increase the material's crushing ratio and improve the machine's operational life.

In addition to its role in size reduction, the moving jaw also influences the size of the output particles. When the angle and motion of the jaw are well-calibrated, the crusher can produce a more uniform particle size distribution, which is essential for various construction applications. Increased precision in the movement translates to better processing and reduced waste, thereby maximizing productivity. Notably, industry studies indicate that improving the design and movement of the jaw can result in efficiency gains of up to 25%, affirming the significance of the moving jaw in driving the performance of stone crushers.

The design of the moving jaw in a stone crusher is a critical factor that significantly influences its overall performance and efficiency. The configuration of the moving jaw determines the size and shape of the crushing chamber, which directly affects how materials are processed. An optimized moving jaw design allows for better material flow, reduces jam occurrences, and enhances the uniformity of the crushed product. By adjusting the angle and length of the moving jaw, engineers can fine-tune the crushing action, resulting in improved throughput and reduced energy consumption.

Additionally, the material used for the moving jaw plays a vital role in its durability and effectiveness. High-quality, wear-resistant materials can extend the lifespan of the jaw, maintaining consistent performance over time. The mechanism by which the moving jaw operates—whether through hydraulic or mechanical means— also impacts the speed and force applied during the crushing process. Consequently, advancements in moving jaw technology can lead to substantial gains in efficiency, enabling crushers to handle varying types of material more effectively while minimizing downtime and maintenance efforts.

The moving jaw is a critical component of a stone crusher, responsible for the crushing action that reduces materials to desired sizes. However, this mechanism can face common issues that may affect its performance. One significant problem is wear and tear due to the constant motion and friction against other components. As the moving jaw operates, it can develop cracks or become misaligned, leading to inefficient crushing and increased energy consumption. Regular visual inspections are essential to identify these issues early on.

To maintain the moving jaw and extend its service life, lubrication is vital. Proper lubrication minimizes friction, reducing wear on the moving parts. Moreover, operators should regularly check the alignment of the moving jaw, ensuring it operates within the specified limits.

Tightening loose bolts and replacing worn-out components promptly can help prevent further damage. Additionally, monitoring the crushing chamber for blockages and ensuring that the material fed into the crusher is within the recommended size can mitigate unnecessary stress on the moving jaw, ultimately enhancing overall performance.