Choosing the right Jaw Crusher Part is crucial for optimal performance. Many factors affect this decision, including material type and application. A well-selected part ensures longevity and efficiency, leading to cost savings.

The market offers various Jaw Crusher Parts, each with distinct features. It's vital to assess the specific needs of your operation. Factors such as size, hardness, and wear resistance come into play. You may find it challenging to identify the best options. Don't rush this process; take the time to research thoroughly.

While many resources suggest looking for the most popular parts, it’s essential to reflect on your unique requirements. Sometimes, the best choices aren't the most recognized ones. Evaluating your operational environment and demands is key to making informed decisions. Finding the right Jaw Crusher Part can be a daunting task, but with care, you can achieve the right balance for your needs.

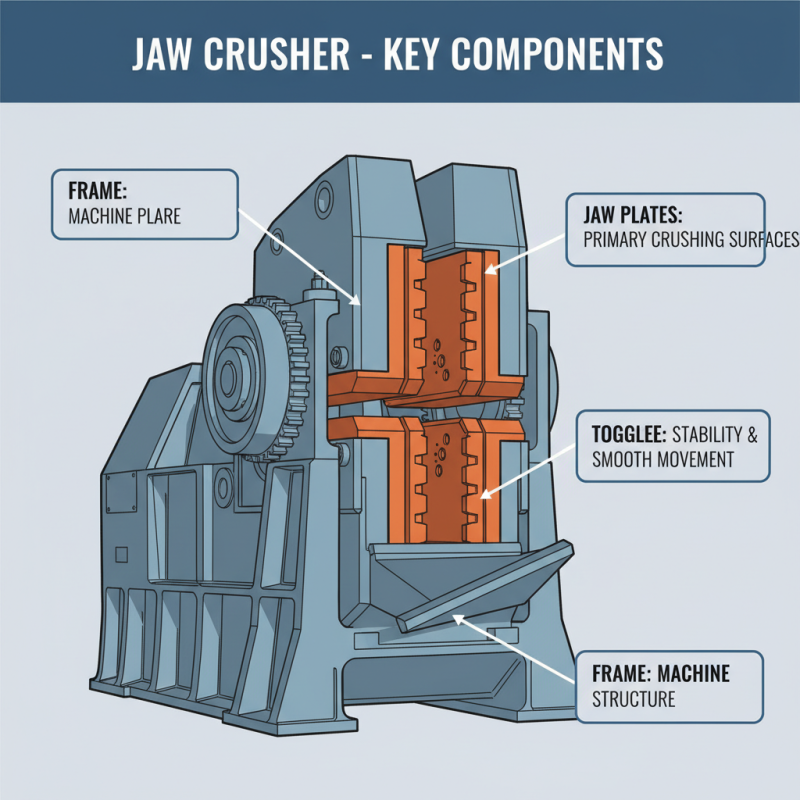

Jaw crushers are essential machines in various industries. Understanding their parts is crucial for effective operation. Key components include the jaw plates, toggle plate, and frame. Each part serves a unique function. The jaw plates are the primary crushing surfaces. They bear the brunt of the material being crushed. The toggle plate ensures stability and helps the jaws move smoothly.

Choosing the right parts can be daunting. Many users overlook wear patterns on jaw plates. This can lead to inefficiencies. You may find that different materials require different part selections. Some jaws work better with softer materials, while others handle hard rocks efficiently. Knowing the type of material you are working with influences your choice.

It’s also important to consider maintenance needs. Parts wear out at different rates. Ignoring this can lead to unexpected downtime. Regular inspections can be beneficial, but they often get neglected. Delaying maintenance can result in larger issues down the line. Investing time in understanding part functions can save costs in the long run.

When selecting jaw crusher parts, consider several critical factors to ensure optimal performance. Material quality is crucial. High-quality materials improve durability and reduce wear. It’s essential to examine the chemical composition of the steel used. Different grades can greatly affect the lifespan of the parts.

Another vital aspect is the compatibility with existing machinery. Not all jaw crushers are the same. Proper sizing and fitting are necessary to prevent issues during operation. Misalignments can lead to unexpected downtime. Additionally, reviewing the design and engineering of the parts may provide insights into their effectiveness.

Maintenance requirements should not be overlooked. Some parts might require frequent inspections and replacements. This can significantly affect operational costs in the long run. Keep in mind that selecting the right part is not always straightforward. It involves trial and error, and sometimes, the cheapest option can lead to more expenses later.

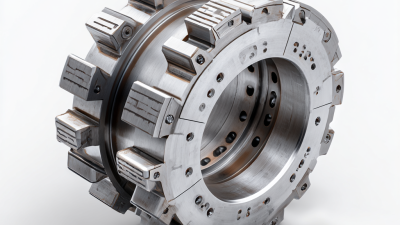

Selecting the right material for jaw crusher components is crucial for improving uptime and efficiency. The materials used can significantly affect durability and performance. Common options include manganese steel, high-carbon steel, and ceramic composites.

Manganese steel, for example, is known for its high impact strength and resistance to deformation. Reports indicate that using manganese steel can increase component lifespan by up to 30%. This makes it a popular choice in many applications.

High-carbon steel, while cost-effective, may not withstand extreme conditions. In contrast, ceramic composites offer exceptional wear resistance. They are lightweight and can minimize the load on the machine. However, their brittle nature can lead to unexpected failures. A study found that 15% of users experienced premature cracking in ceramic parts when used improperly. This highlights the importance of understanding material properties thoroughly.

When selecting materials, it's vital to consider the specific operational environment. Factors such as temperature, load, and material type being crushed should guide your choice. Using the wrong material can lead to increased maintenance costs and unscheduled downtime. Though economical options are tempting, the long-term implications can outweigh initial savings. It’s essential to strike a balance between cost and performance to achieve optimal results.

Selecting the right jaw crusher part starts with understanding your existing model. Each jaw crusher is unique, with specific measurements and designs. It's vital to check compatibility before making any purchase. Whether you're replacing wear parts or the entire assembly, dimensions matter a lot.

Knowing the specifications of your current jaw crusher can save time and money. Parts that don’t fit can lead to operational issues. Misalignment can cause premature wear or even complete failure. A precise match ensures optimal performance. Consider the manufacture date; older models may require specialized parts.

Also, be cautious with online purchases. Some sellers may not provide accurate information. Requesting additional details can clarify any doubts. Always cross-reference with your machine's manual. It's better to double-check than to deal with costly mistakes. The right choice can enhance efficiency and extend the life of your equipment.

| Jaw Crusher Model | Part Type | Material | Compatibility | Warranty |

|---|---|---|---|---|

| Model A | Fixed Jaw Plate | Manganese Steel | Yes | 1 Year |

| Model B | Swing Jaw Plate | High Carbon Steel | Yes | 6 Months |

| Model C | Side Liners | Chrome Manganese | Yes | 2 Years |

| Model D | Toggle Plate | Steel Alloy | No | 1 Year |

| Model E | Bearings | Bronze | Yes | 6 Months |

When maintaining jaw crushers, the right parts are crucial. A report by the International Journal of Engineering and Technology suggests that 60% of operational downtime is due to part failures. Choosing the correct wear parts significantly impacts productivity. Quality is vital, but so is compatibility with existing machinery.

Regular inspections are necessary. Inspect the wear parts every few weeks. Look for cracks or severe wear that may indicate replacement needs. Experts recommend keeping a log of parts performance. It can help identify patterns over time. This can prevent unexpected failures.

Additionally, consider the materials used in parts. Using high-quality materials can enhance durability. Yet, some companies cut costs by using subpar materials. This may result in frequent breakdowns. The trade-off may seem appealing initially. In the long run, it increases maintenance efforts. Ultimately, a thorough understanding of your specific needs can guide you in selecting the right parts for your jaw crusher.