In the world of mineral processing and construction, the importance of high-quality crushing equipment cannot be overstated. Among these essential components, the Stone Crusher Fixed Jaw plays a pivotal role in optimizing performance and ensuring operational efficiency. According to a report by industry analysts, the global stone crushing equipment market is projected to reach nearly $8 billion by 2025, driven by the increasing demand for aggregates in construction and road development. However, issues such as wear and tear, misalignment, and inadequate maintenance can severely impact the effectiveness of the fixed jaw, leading to operational disruptions and increased costs. Understanding the significance of the Stone Crusher Fixed Jaw and addressing potential problems can greatly enhance productivity and longevity, making it a crucial focus for any crushing operation.

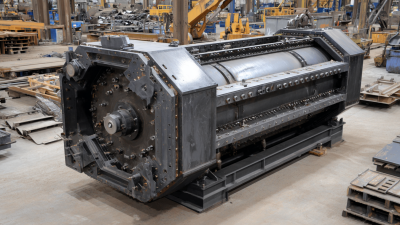

The fixed jaw is a fundamental component in stone crushing operations, playing a vital role in the efficiency of the process. It serves as a stable base that ensures the material being crushed stays in place while exerting an upward force against the moving jaw. This stability is essential for achieving consistent results, reducing wear and tear on other machine parts, and ultimately increasing the lifespan of the equipment.

Moreover, the design and hardness of the fixed jaw significantly impact the crushing efficiency. A well-structured fixed jaw can handle the rigors of crushing various materials, allowing for a more substantial and uniform output. In addition, it aids in reducing the energy consumption of the crushing operation—when the fixed jaw performs its role effectively, the overall power required per ton of material processed can be diminished, leading to cost savings and enhanced productivity for operators.

The fixed jaw is a crucial component in stone crushing operations, serving as the backbone for the crushing process. However, it is not without its common issues that can significantly affect performance. One prevalent problem is wear and tear due to the constant high-stress environment in which the fixed jaw operates. Studies indicate that improper alignment or significant wear can lead to uneven pressure distribution, which may compromise the efficiency of the crushing chamber. For optimal design, it is essential to evaluate the materials used and their stress tolerance, as seen in recent research highlighting the finite element analysis of components in engineering applications.

The fixed jaw is a crucial component in stone crushing operations, serving as the backbone for the crushing process. However, it is not without its common issues that can significantly affect performance. One prevalent problem is wear and tear due to the constant high-stress environment in which the fixed jaw operates. Studies indicate that improper alignment or significant wear can lead to uneven pressure distribution, which may compromise the efficiency of the crushing chamber. For optimal design, it is essential to evaluate the materials used and their stress tolerance, as seen in recent research highlighting the finite element analysis of components in engineering applications.

Moreover, the stress distribution analysis, similar to techniques used in evaluating dental prosthetics, can provide insights into the structural integrity of the fixed jaw under operational loads. Innovative designs focusing on optimizing the frame and jaw plates can greatly enhance durability and performance. By proactively addressing these issues, operators can reduce downtime and maintenance costs, thereby ensuring a more efficient and reliable crushing operation. As the industry evolves, employing advanced analytical techniques will be key to overcoming the challenges associated with fixed jaw components.

The performance of a stone crusher is heavily influenced by the condition of its fixed jaw. Over time, wear and tear can significantly impact the crushing efficiency and output quality. When the fixed jaw suffers from abrasion or deformation, it can lead to an inconsistent crushing process. This not only affects the size reduction of aggregates but also increases the likelihood of producing fines, which can degrade the overall quality of the material being processed.

Additionally, a compromised fixed jaw can strain other components of the crushing system, leading to increased maintenance costs and downtime. Regular inspection and timely replacement of the fixed jaw are essential to mitigate these issues. By ensuring that the fixed jaw is in optimal condition, operators can maintain high throughput rates and reduce the risk of costly breakdowns. In essence, investing in the longevity of the fixed jaw directly correlates with enhanced operational efficiency and resource management in crushing operations.

Maintenance of the fixed jaw is crucial for ensuring the longevity and efficiency of stone crushing operations. One effective strategy is to implement a regular inspection schedule. Frequent examinations help identify wear and tear before it escalates into significant issues. During inspections, operators should check for signs of cracks, misalignment, or excessive wear on the jaw surface. Early detection enables timely repairs or replacements, thereby minimizing downtime and enhancing productivity.

Another key maintenance strategy involves proper lubrication. Ensuring that the fixed jaw and its associated components are adequately lubricated can significantly reduce friction and wear, prolonging service life. Operators should use the manufacturer-recommended lubricants and adhere to specified lubrication intervals. Additionally, maintaining a clean operational environment helps prevent contaminants from entering the system, which can lead to premature failure of the fixed jaw. By combining regular inspections with proper lubrication and cleanliness, crushing operations can effectively mitigate potential fixed jaw problems, ensuring smooth and efficient performance.

| Reason | Description | Maintenance Strategy | Frequency |

|---|---|---|---|

| Durability | Fixed jaws are crucial for withstanding high pressures during crushing. | Regular inspection for wear | Monthly |

| Efficiency | Ensures optimal performance and reduces downtime. | Lubricate moving parts | Weekly |

| Alignment | Proper alignment leads to effective material processing. | Check and recalibrate as needed | Quarterly |

| Safety | Fixed jaws contribute to overall equipment safety during operations. | Conduct safety audits | Biannually |

| Cost-Effectiveness | Reduces replacement costs by maintaining fixed jaws. | Implement a wear-monitoring program | As needed |

| Material Quality | Essential for achieving desired product size and quality. | Regularly evaluate output material | Monthly |

| Technological Advancements | Keeping up with new jaw designs can improve performance. | Stay updated on industry trends | Annually |

When it comes to optimizing crushing operations, selecting the right fixed jaw is critical for maximizing efficiency and reducing operational costs. According to a report by the Mining Industry Association, the crusher's jaw configuration can significantly impact the material's flow and output quality, with studies showing that a well-designed fixed jaw can improve the reduction ratio by up to 30%. This not only enhances performance but also minimizes wear and tear on other components, ultimately extending the lifespan of the equipment and reducing maintenance expenses.

Moreover, the material composition of the fixed jaw plays a vital role in its durability and effectiveness. Professional benchmarking studies indicate that using high-quality alloy steel for fixed jaws can increase their lifespan by more than 50% compared to standard materials. Such longevity is crucial in high-stress environments, where downtime translates into significant loss of productivity. Therefore, investing in the right fixed jaw design and material is not merely a choice; it is an essential strategy for any crushing operation aiming for optimal performance and long-term success.