In the world of mining and aggregate production, optimizing equipment efficiency is crucial for maintaining competitiveness and profitability. One key component that significantly impacts the performance of a cone crusher is the cone crusher bowl liner. This essential part not only plays a vital role in the crushing process but also affects the overall wear and operational costs of the machinery.

By understanding the benefits of effectively optimizing your cone crusher bowl liner, operators can achieve maximum efficiency, leading to reduced downtime and improved output quality. This blog will delve into various strategies and best practices for enhancing the performance of your cone crusher bowl liner, exploring how proper selection, maintenance, and adjustment can lead to substantial benefits in productivity and cost-effectiveness.

By understanding the benefits of effectively optimizing your cone crusher bowl liner, operators can achieve maximum efficiency, leading to reduced downtime and improved output quality. This blog will delve into various strategies and best practices for enhancing the performance of your cone crusher bowl liner, exploring how proper selection, maintenance, and adjustment can lead to substantial benefits in productivity and cost-effectiveness.

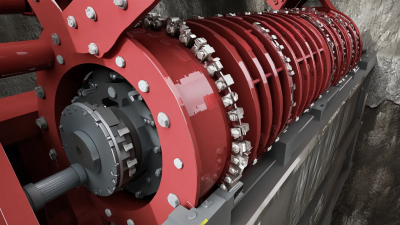

The bowl liner in a cone crusher plays a crucial role in optimizing the overall efficiency of the crushing process. These liners serve as a barrier that helps direct the materials through the crushing chamber. According to a report by the Mining Journal, properly maintained and optimized bowl liners can increase throughput by up to 20%. This optimization reduces the need for frequent maintenance and decreases operational costs, making it essential for quarry operators to understand the influence of bowl liners on performance.

Moreover, the material composition of the bowl liner significantly affects its durability and performance. Research from the Journal of Materials Science highlights that high-quality manganese steel liners can enhance wear resistance, leading to extended lifespans and reduced operational downtimes. A well-chosen liner profile not only helps to maximize the reduction ratio but also ensures that the crusher operates within the desired power range. Detailed analysis indicates that an optimized liner profile can improve energy efficiency by up to 15%, translating into substantial cost savings for operators in the competitive mining sector.

The performance of bowl liners in cone crushers is significantly influenced by several key factors that determine both efficiency and longevity. One major factor is the material composition of the bowl liner itself. High-quality steel alloys with enhanced wear resistance are essential for maintaining structural integrity while minimizing wear over time. Additionally, the manufacturing process, which includes precision casting and heat treatment, plays a critical role in achieving the desired hardness and toughness, directly impacting the liner's performance in harsh crushing environments.

Another crucial factor is the design and geometry of the bowl liner. The shape and profile must be optimized to facilitate better material flow and to achieve a more effective crushing action. Variations in the liner’s profile can affect the size distribution of the crushed material, influencing the overall efficiency of the crushing process. Furthermore, regular monitoring and adjustment of the gap settings between the liner and the mantle can ensure optimal material throughput and prevent excessive wear, leading to increased productivity and reduced operational costs.

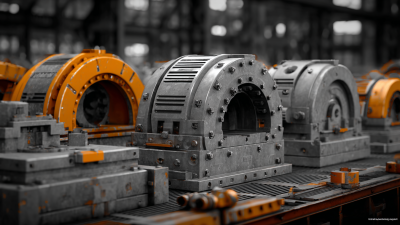

Optimizing your cone crusher's bowl liner design is crucial for enhancing operational efficiency and prolonging equipment life. A well-designed bowl liner not only improves the fragmentation of materials but also maximizes the throughput of your crushing system. According to a report by the Mining Industry Council, proper liner design can boost productivity by up to 25%, highlighting the importance of meticulous attention to detail when selecting materials and profiles.

One effective technique is to match the bowl liner profile with the type of material being processed. For instance, using a convex shape for hard rock can significantly increase efficiency. Additionally, consider implementing a manganese alloy that exhibits superior wear resistance. This approach ensures that your bowl liner maintains its integrity longer, reducing the frequency of replacements.

Tip: Regularly monitor the wear patterns of your bowl liner. By analyzing these patterns, you can make informed decisions on when to adjust or replace liners, ultimately leading to decreased downtime and optimal performance. Another key consideration is the selection of an appropriate backing material. A high-quality backing compound can mitigate vibrations and enhance the overall lifespan of the liner, allowing for smoother operations.

Maintaining the bowl liner of your cone crusher is essential for ensuring optimal performance and longevity. Regular inspections are crucial to identify wear and tear that might impact efficiency. High-priority violations in maintenance practices can severely hinder a crusher's operation, much like how failing restaurant inspections can affect public perception and safety. By implementing a robust inspection schedule, operators can detect early signs of wear and take corrective measures before the issues escalate.

Best practices for maintenance include thorough cleaning of the bowl liner and surrounding components to prevent buildup that could lead to premature wear. Additionally, ensuring that the liner is correctly installed and secured will contribute to better efficiency and safety. Just as restaurants rely on strict guidelines to pass health inspections, cone crusher operators should adhere to manufacturer recommendations and industry standards to maintain their equipment. This proactive approach not only maximizes production efficiency but also extends the life of the bowl liner, ultimately leading to a more profitable operation.

When it comes to optimizing your cone crusher's bowl liner, the choice of materials plays a critical role in enhancing both longevity and performance. Advanced materials such as high-alloy steel and specialized ceramics can provide superior wear resistance and structural integrity, allowing the liner to withstand extreme conditions and extend its operational life. Investing in these advanced materials not only boosts productivity but also minimizes downtime and maintenance costs.

Tip 1: Regularly evaluate the bowl liner's wear pattern to identify areas of high stress. This assessment can inform your decisions on when to replace or adjust the liner, ultimately leading to improved efficiency and reduced material waste.

Tip 2: Consider upgrading to a bowl liner with a unique profile or design that matches your specific crushing requirements. Tailored geometries can significantly enhance material flow and reduce the likelihood of blockages, maximizing throughput.

Incorporating these advanced materials and techniques not only optimizes the performance of your cone crusher but also ensures that your operations remain efficient and cost-effective in the long run.