In the ever-evolving world of mining, the importance of optimizing equipment performance cannot be overstated, especially when it comes to Mining Stone Crusher Parts. According to a recent report by the Global Mining Equipment Market Analysis, the efficient operation of crushing machinery can lead to productivity enhancements of up to 30%, directly impacting a mining company's bottom line. As the industry gears up for significant advancements in 2025, understanding the latest innovations in stone crusher components has become vital for stakeholders looking to stay competitive.

Renowned industry expert Dr. Michael T. Harris, an authority in mining technology, emphasizes the critical role of these components, stating, "Investing in high-quality Mining Stone Crusher Parts is not just about durability; it's about ensuring peak performance and efficiency throughout the mining process." With rising demands for raw materials and the strain on existing resources, the need for reliable and efficient crushing solutions will only intensify. Consequently, mining companies must prioritize the adoption of advanced parts and technologies to enhance their operational efficacy and sustainability in the forthcoming years.

As we look towards 2025, the focus on Mining Stone Crusher Parts will not only facilitate better performance but also contribute to the overall growth and innovation within the mining sector. By leveraging cutting-edge technologies and materials, organizations can ensure their machinery operates at peak capacity, reducing downtime and ultimately maximizing output in an increasingly competitive landscape.

In the highly competitive landscape of mining, efficiency is paramount. As we look towards 2025, the focus on optimizing stone crusher parts plays a crucial role in enhancing operational performance. Key components such as high-quality liners, durable hoppers, and efficient jaw plates are vital for minimizing downtime and increasing throughput. These parts are designed not only for longevity but also for better compatibility with various materials, ensuring the machines can handle the toughest crushing tasks with ease.

In addition to the mechanical aspects, advancements in technology are paving the way for smarter crushing solutions. Parts that integrate with monitoring systems enable predictive maintenance, helping operators identify wear and tear before it becomes a critical issue. Furthermore, investing in upgraded components with improved design can lead to more efficient energy consumption, providing a sustainable advantage. As we prepare for the future, selecting the right stone crusher parts is essential for achieving enhanced efficiency and profitability in mining operations.

When selecting high-performance crusher parts for mining operations in 2025, several key specifications must be considered to maximize crushing efficiency. One of the most critical attributes is the material composition of the parts. Utilizing high-alloy steels or premium-grade manganese can significantly improve wear resistance and extend the lifespan of the components. This is particularly important in mining environments where durability is essential to withstand heavy impacts and abrasive materials.

Another vital specification is the design and geometry of the crusher parts. Parts that feature optimized shapes, such as concaves and mantles with enhanced profiles, can facilitate better material flow, reduce blockages, and improve overall throughput. Additionally, attention should be given to the fit and tolerances of the components to ensure seamless integration within the crushing system, which can lead to reduced maintenance downtime and lower operational costs.

By focusing on these specifications, mining operations can enhance their crushing efficiency and ensure sustained productivity in the competitive landscape of 2025.

The efficiency of crushing operations in mining relies heavily on the wear resistance of crusher components. A comparative analysis of materials used in mining crusher parts reveals significant differences in their longevity and performance under harsh conditions. According to a recent industry report, components made from high manganese steel can offer a wear life that is 30% longer than those made from standard steel under similar operating conditions. This enhanced durability not only reduces downtime for replacements but also increases overall productivity in mining operations.

When evaluating materials for mining crusher parts, it's essential to consider factors such as hardness and impact resistance. Advanced alloys, which incorporate elements like chromium and molybdenum, show superior wear resistance and can withstand the abrasive nature of rock crushing. Studies indicate that using parts made from these advanced materials can lead to a reduction in operational costs by up to 20% over a year, primarily due to decreased maintenance needs and increased operational efficiency.

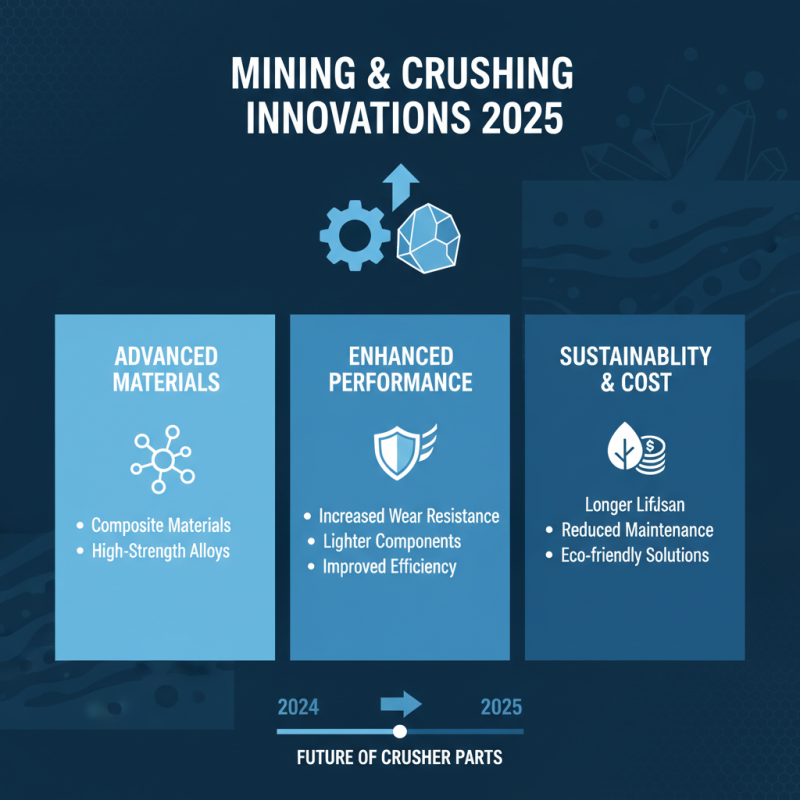

The landscape of mining and stone crushing is continuously evolving, with innovative materials leading the charge in enhancing the efficiency and durability of crusher parts. As we look to 2025, the integration of advanced composite materials and high-strength alloys is set to redefine the performance metrics of stone crushers. These innovations not only promise increased resistance to wear and tear but also allow for lighter components that can bolster operational efficiency. With the demand for more sustainable and cost-effective mining solutions growing, manufacturers are shifting towards materials that offer longer lifespans and reduced maintenance needs.

Moreover, the use of smart materials, which can adapt to various operational stresses, is becoming more prevalent in the industry. These materials are engineered to respond dynamically to changes in load and temperature, ensuring optimal performance under challenging conditions. As the industry embraces these cutting-edge solutions, the performance of stone crushers will vastly improve, resulting in higher throughput and lower energy consumption. This shift not only secures competitive advantages for operations but also aligns with broader sustainability goals, making innovative materials a central theme in the future of stone crusher parts.

The mining industry is on the verge of significant evolution, particularly in the area of equipment maintenance and parts lifespan. Reports indicate that as we approach 2025, mining companies are projected to prioritize the optimization of maintenance schedules to minimize downtime and improve operational efficiency. A study from the International Council on Mining and Metals highlights that proactive maintenance can increase equipment availability by up to 20%. This shift is largely driven by the increasing complexity of mining machinery and the necessity for parts that can withstand harsh environments.

Preventative maintenance practices now focus not just on replacing worn-out components but also on understanding usage patterns and predictive analytics. It is estimated that utilizing data-driven strategies could extend the lifespan of critical parts by 15% to 25%. By incorporating technologies such as IoT sensors and real-time monitoring tools, mining operations can gather valuable insights, enabling timely interventions that prevent costly breakdowns.

Tips: To enhance the lifespan of your mining equipment, consider implementing a routine inspection protocol, ensuring all components are regularly checked for wear and tear. Additionally, investing in high-quality parts and technologies that allow for better monitoring can significantly reduce repair costs and downtime. Establishing a partnership with suppliers who focus on durability and service can further support your maintenance strategies for optimal efficiency in 2025 and beyond.