The mining industry significantly relies on the efficiency and durability of its equipment. Among these, Mining Machinery Jaw Plates play a crucial role. They are essential components in crushers, which break down materials for further processing. According to a report by Grand View Research, the global mining equipment market is expected to grow at a CAGR of 5.3% from 2021 to 2028, highlighting the increasing demand for efficient machinery and parts.

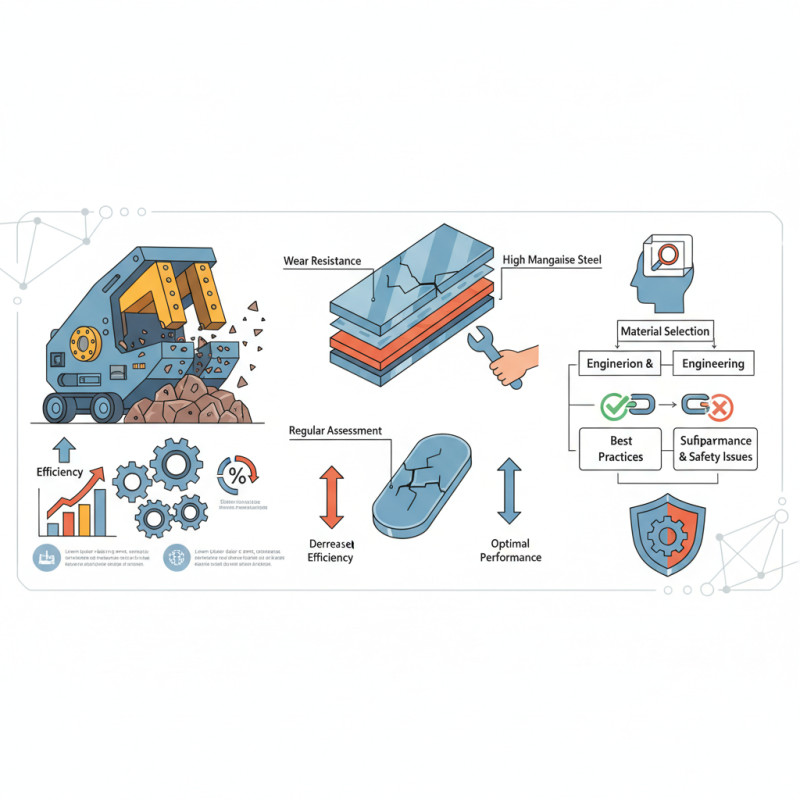

As noted by industry expert Dr. Thomas Greene, “High-quality jaw plates are vital for maximizing the performance of mining crushers.” His insights emphasize the importance of durable materials and precise engineering in jaw plate design. However, many operators overlook regular maintenance. This neglect can lead to decreased efficiency and increased operational costs. It's essential to regularly assess and replace jaw plates to maintain optimal performance.

Moreover, the choice of materials can impact wear rates significantly. High manganese steel, for instance, is commonly used for its resistance to wear. Yet, not all manufacturers adhere to best practices in material selection. This inconsistency can lead to subpar performance and safety issues. Addressing these concerns requires a comprehensive understanding of the equipment and proactive management strategies.

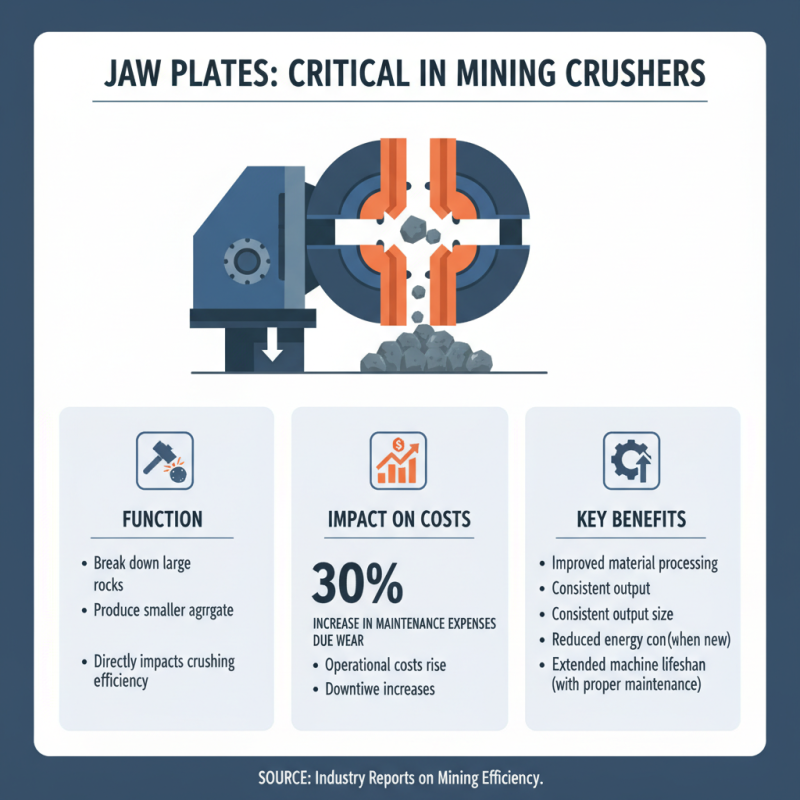

Jaw plates play a crucial role in mining machinery, particularly in jaw crushers. These components are designed to break down large rocks into smaller pieces. They directly impact the efficiency and effectiveness of the crushing process. According to industry reports, wear and tear of jaw plates can significantly affect operational costs, leading to a 30% increase in maintenance expenses.

The material composition of jaw plates is vital. High-manganese steel is common due to its excellent wear resistance. However, durability often requires a trade-off between toughness and hardness. Some manufacturers struggle to find the right balance. Ineffective heat treatment processes can also lead to premature failure. This is not ideal for any operation relying on consistent output.

Regular monitoring and timely replacement of jaw plates are necessary to maintain optimal performance. As research indicates, outdated or worn jaw plates can reduce throughput by nearly 20%. This reduction can lead to longer operational hours and increased labor costs. Yet, many companies overlook this aspect. They need to recognize the importance of proactive maintenance in mining operations.

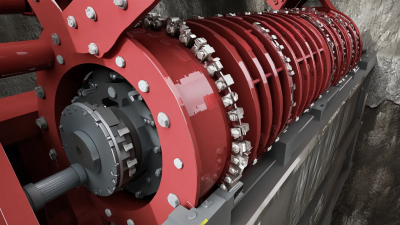

Jaw plates are crucial components in mining machinery, particularly in crushers. They directly affect the efficiency and performance of the equipment. These plates endure high wear and tear due to their constant interaction with hard materials. Understanding the materials used to manufacture jaw plates helps in selecting the best options for various applications.

Typically, jaw plates are made from materials like manganese steel and other alloys. Manganese steel provides high impact strength and abrasion resistance. It is known for its ability to withstand severe crushing conditions. Some manufacturers also explore alternative materials, such as high carbon steel or ceramic composites. However, these options may not offer the same lifespan as manganese steel.

In manufacturing, the choice of material significantly impacts performance. Sometimes, softer alloys are used to reduce costs, but they wear out faster. Companies must balance cost and durability when selecting materials. A poor choice can lead to frequent replacements and downtime. This highlights the importance of thorough research before making decisions.

Jaw plates play a critical role in mining machinery, particularly in jaw crushers. These components are essential for crushing materials efficiently. A well-designed jaw plate can enhance the crushing process and improve productivity. According to industry reports, the wear and tear of jaw plates significantly affect the operational efficiency of mining equipment, often leading to increased downtime and maintenance costs.

The significance of jaw plates lies in their ability to withstand heavy workloads. They help in breaking down large rocks into smaller, manageable sizes. Various material compositions, such as high manganese steel, provide the needed durability. A report by the Mining Equipment Manufacturers points out that jaw plates made from advanced alloys can improve wear resistance by up to 30%. This translates to longer service life and reduced replacements.

Tips: Regularly monitor the condition of your jaw plates. Small cracks can lead to larger issues. Consider using a scheduled maintenance plan to catch wear early. Pay attention to your crushing process; sometimes, inefficiencies arise from misalignment rather than jaw plate degradation.

| Dimension | Value | Significance |

|---|---|---|

| Material Type | High Manganese Steel | Excellent hardness and wear resistance |

| Thickness | 40 mm | Provides durability for crushing operations |

| Weight | 500 kg | Stability and reduction of vibration during operation |

| Hardness | Rockwell C 50-55 | Ensures longevity and performance during crushing |

| Service Life | 2,000 hours | Reduces replacement frequency and operational costs |

| Applications | Metal Ore, Aggregate Production | Versatile for different mining operations |

Jaw plates are essential components of mining machinery. They help in crushing materials like rocks and ores. Proper maintenance is crucial for their longevity. Worn-out jaw plates can lead to inefficient crushing. This not only affects productivity but can also cause operational delays. Regular inspections help identify wear and tear early.

It's important to check for cracks and deformities. Even minor damages can escalate quickly if not addressed. When replacing jaw plates, ensure that they fit correctly. Misalignment can lead to further damage to the machinery. Using high-quality materials for replacement is also essential. Inferior parts can wear out faster.

In addition to checking wear levels, it’s wise to track the machine’s performance. Unexpected vibrations or noises may indicate a problem. Such issues might be easy to overlook but can have serious impacts. Developing a routine maintenance schedule can help in preventing failures. It's about being proactive, not reactive. Proper upkeep of jaw plates can significantly enhance efficiency and save costs in the long run.

This bar chart illustrates the frequency of maintenance tasks carried out on jaw plates, highlighting their importance in mining machinery operations. Regular maintenance ensures optimal performance and longevity of equipment.

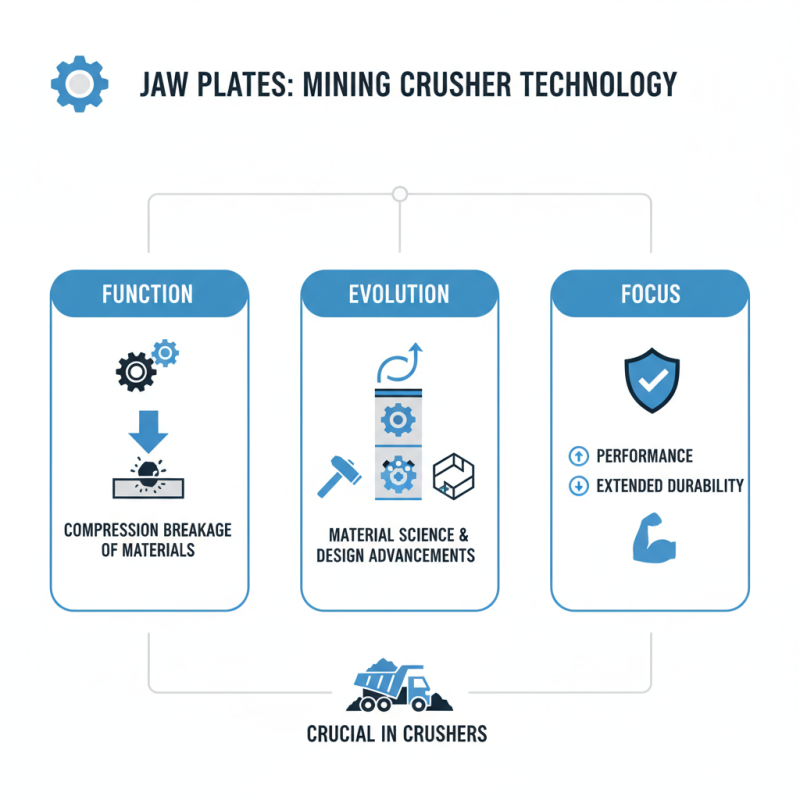

Jaw plates are crucial components in mining machinery, specifically in crushers. They play a significant role in breaking down materials through a process of compression. The technology behind jaw plates has evolved considerably over the years. Various manufacturers focus on enhancing performance and durability.

Many key manufacturers innovate with materials and design. They use advanced alloys and heat treatment processes. These innovations are vital for improving jaw plate longevity. New designs can increase the efficiency of material handling. Some experimental models show promise but need further testing. Innovations also include replacing traditional materials with lightweight composites.

The importance of these advancements cannot be overstated. Better jaw plates lead to reduced downtime. This translates to more efficient operations. Operations that do not invest in modern technology may face challenges.

**Tip:** Regularly inspect jaw plates to assess wear and tear.

Monitoring their condition is essential for a seamless workflow. It's easy to overlook maintenance, but neglect can lead to significant losses.

**Tip:** Consider adopting predictive maintenance strategies.

Using data analytics can help anticipate failures. This proactive approach can improve your overall efficiency and productivity. Implementing such measures may seem daunting, but the benefits are clear.