Mining Machinery Jaw Plates are essential components in the crushing process of various materials. According to industry expert John Smith, “The durability and efficiency of jaw plates can significantly impact production.” This highlights their critical role in mining operations.

These plates serve as the primary interface between the crushing machine and the materials being processed. Their design is crucial for effective crushing. Different materials require specific jaw plate designs. The wrong choice may lead to inefficient operations.

Jaw plates can minimize wear and tear. However, they are not immune to damage. Regular inspection and replacement are necessary to maintain optimal performance. Neglecting this can lead to costly downtimes. Understanding the benefits of Mining Machinery Jaw Plates helps in selecting the right type for various applications. It is an area where many companies can improve efficiency.

Jaw plates are crucial components in mining machinery, specifically in crushers. They act as a barrier that crushes materials like rocks and minerals. Typically made of high-strength steel, they bear the brunt of intense pressure. Over time, they wear down, impacting efficiency and productivity. Replacing or maintaining these plates is essential for smooth operations.

The design of jaw plates affects performance. Some may be too thick, causing ineffective crushing. Others might wear unevenly, leading to disruptions. It's important to choose the right material and size. This can enhance the life span of the jaw plates significantly. Regular inspections can help prevent unexpected breakdowns.

Understanding jaw plates means recognizing their role in the entire crushing process. A well-functioning plate encourages better output and minimizes downtime. Yet, improper installations can lead to disasters. Attention to detail in the setup is necessary, and misjudgments can have costly consequences. Selecting the right jaw plates ultimately impacts overall productivity and efficiency.

Jaw plates are essential components in mining machinery. They play a crucial role in crushing materials effectively. Understanding the materials used in jaw plate manufacturing reveals their strength and durability. Typically, high manganese steel is favored for its excellent wear resistance. This material can withstand significant tension and impact, making it ideal for heavy-duty operations. Reports suggest that jaw plates made from this steel can last up to 3 times longer than those made from standard materials.

The structural analysis of jaw plates highlights the importance of design. A well-designed jaw plate optimizes the crushing process. Factors such as hardness, thickness, and surface treatment all contribute to its performance. Some jaw plates have a smooth surface, while others include a corrugated design. The choice affects the friction and, consequently, the efficiency of material processing. Industry data indicates that optimizing these features can improve production rates by 10-15%. Yet, many manufacturers still overlook these aspects, leading to subpar performance.

Challenges persist in sourcing the right materials as well. Not all steel is the same. Variability in quality can affect the lifespan of jaw plates. Poor-grade steel can lead to premature wear, increasing operational costs. Additionally, unexpected failures can halt production. Industries need to remain vigilant in selecting materials to avoid these pitfalls. While advancements are made, there is always room for improvement in the manufacturing process and quality control measures.

| Material | Tensile Strength (MPa) | Hardness (HRC) | Applications | Benefits |

|---|---|---|---|---|

| High Manganese Steel | 850 | HRC 12-14 | Primary and secondary crushing | Excellent impact resistance |

| Alloy Steel | 900 | HRC 30-40 | Mining and aggregate processing | Good wear resistance |

| Tool Steel | 950 | HRC 45-55 | High-performance crushing | Long service life |

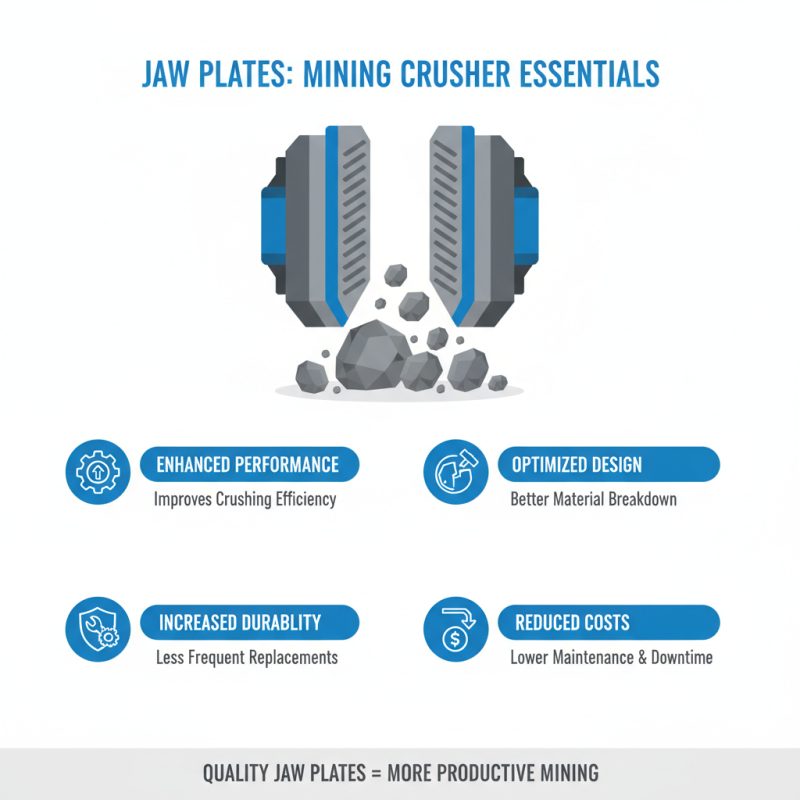

Jaw plates play a crucial role in mining machinery. They are essential components in crushers used to break down rocks. High-quality jaw plates enhance equipment performance significantly. Their design influences how efficiently materials are crushed. Durable plates reduce the frequency of replacements, translating to lower maintenance costs.

Better jaw plates also ensure more uniform feeding of materials. This improved flow can lead to higher output rates. Operators often overlook the importance of quality. However, investing in reliable jaw plates can yield higher profits. There can be complications, though. Even the best materials wear over time. Regular inspections and timely replacements are crucial.

In the demanding environment of mining, efficiency is king. Quality jaw plates can lead to smoother operations. They not only extend the lifespan of the machinery but also decrease unexpected downtimes. Ultimately, a slight improvement can have a large impact. Taking shortcuts here may cost more in the long run. The mining industry relies heavily on these essential components. They are often the backbone of successful crushing operations.

Jaw plates play a critical role in mining machinery, particularly in crushers. They are designed to withstand severe wear and tear. These components are usually made from high-quality steel or manganese steel. The material choice directly affects durability and performance.

Industry standards dictate that jaw plates should meet specific specifications. For instance, ASTM A128 is a common standard for austenitic manganese steel casting. According to mining reports, using jaw plates that meet such standards can reduce operational costs by as much as 25%. Properly designed jaw plates improve crushing efficiency. They help maintain consistent product size and reduce maintenance downtime.

However, not all jaw plates perform equally. Some may wear out faster due to subpar materials or improper design. Research indicates that jaw plates can lose up to 30% of their thickness within weeks. This wear can lead to unplanned stoppages and costly repairs. Mining professionals often face challenges in selecting the right profile for their specific applications. Adjusting the profile can significantly influence performance. A lack of understanding can result in inefficiencies.

Jaw plates are critical components in mining machinery. They are used in crushers to break down ore and rock. The design of these jaw plates can significantly impact performance. A well-designed jaw plate can improve productivity and reduce wear.

In comparing different jaw plate designs, factors such as material composition and geometry play vital roles. Some designs offer better grip, while others enhance the crushing force. A thicker jaw plate may resist wear better, but it can also increase the machine's weight. Finding the right balance between durability and efficiency is crucial.

**Tips:** Regularly inspect jaw plates for wear. This can prevent unexpected breakdowns. Consider the type of material you are crushing. Different materials may require different jaw plate designs for optimal performance. A good design will often reveal itself in operational efficiency, but it may take time to find the most effective option for your specific needs.