In the competitive realm of mining and aggregate production, optimizing operational efficiency is crucial, with maintenance playing a pivotal role in maximizing savings. Among the array of components in cone crushers, the Countershaft Bushing Cone Crusher stands out due to its significant contribution to the machine's performance and durability. According to a recent industry report by the Mining Equipment Association, improperly maintained bushings can lead to a 20% reduction in equipment lifespan and a staggering increase in downtime costs, which can exceed $500,000 annually for high-volume operations. Therefore, implementing effective maintenance strategies not only enhances the longevity of countershaft bushings but also ensures consistent and reliable crushing performance. This blog will delve into detailed technical parameters and practical maintenance tips tailored to help operators achieve optimal performance and savings.

In the competitive realm of mining and aggregate production, optimizing operational efficiency is crucial, with maintenance playing a pivotal role in maximizing savings. Among the array of components in cone crushers, the Countershaft Bushing Cone Crusher stands out due to its significant contribution to the machine's performance and durability. According to a recent industry report by the Mining Equipment Association, improperly maintained bushings can lead to a 20% reduction in equipment lifespan and a staggering increase in downtime costs, which can exceed $500,000 annually for high-volume operations. Therefore, implementing effective maintenance strategies not only enhances the longevity of countershaft bushings but also ensures consistent and reliable crushing performance. This blog will delve into detailed technical parameters and practical maintenance tips tailored to help operators achieve optimal performance and savings.

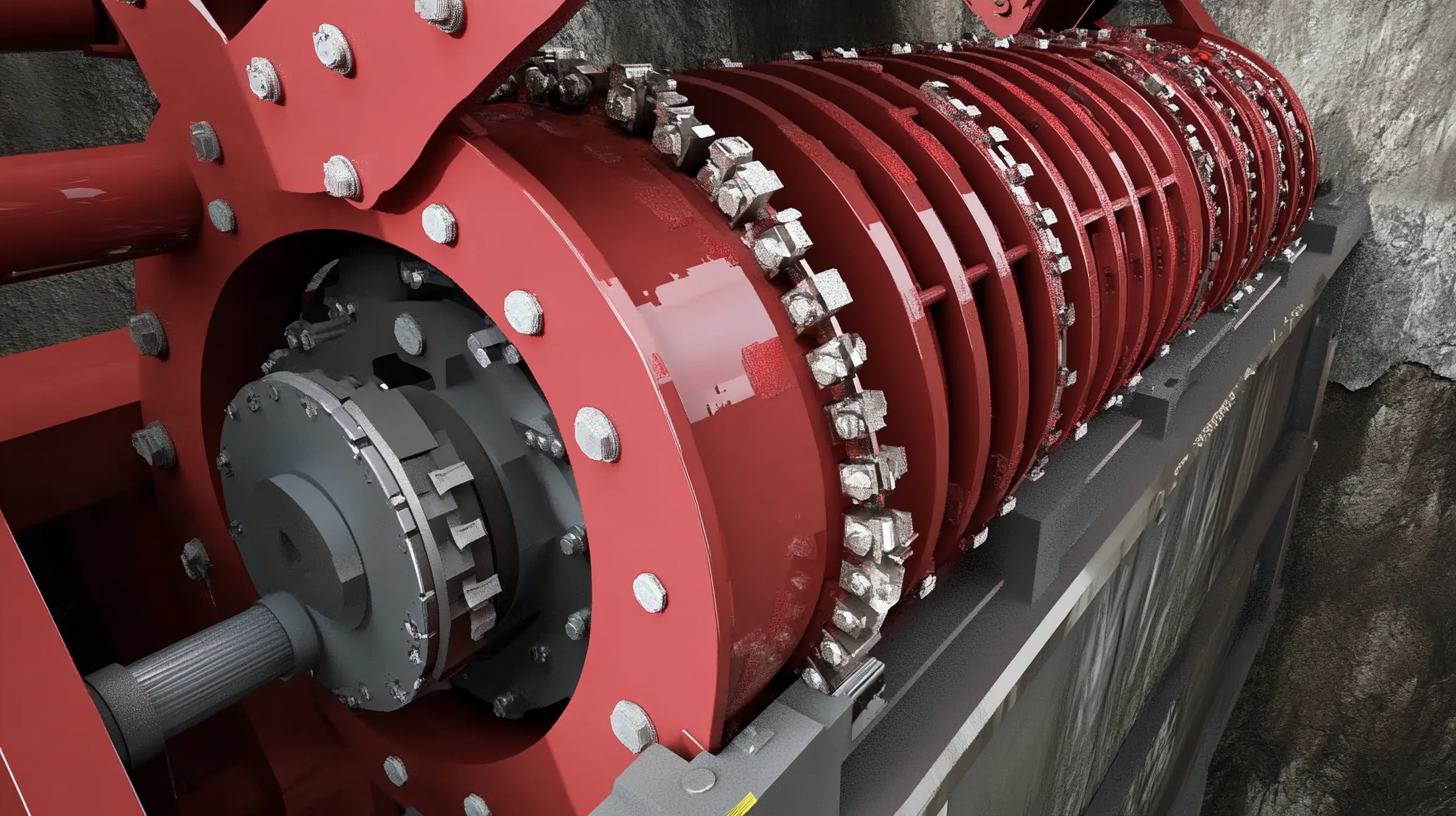

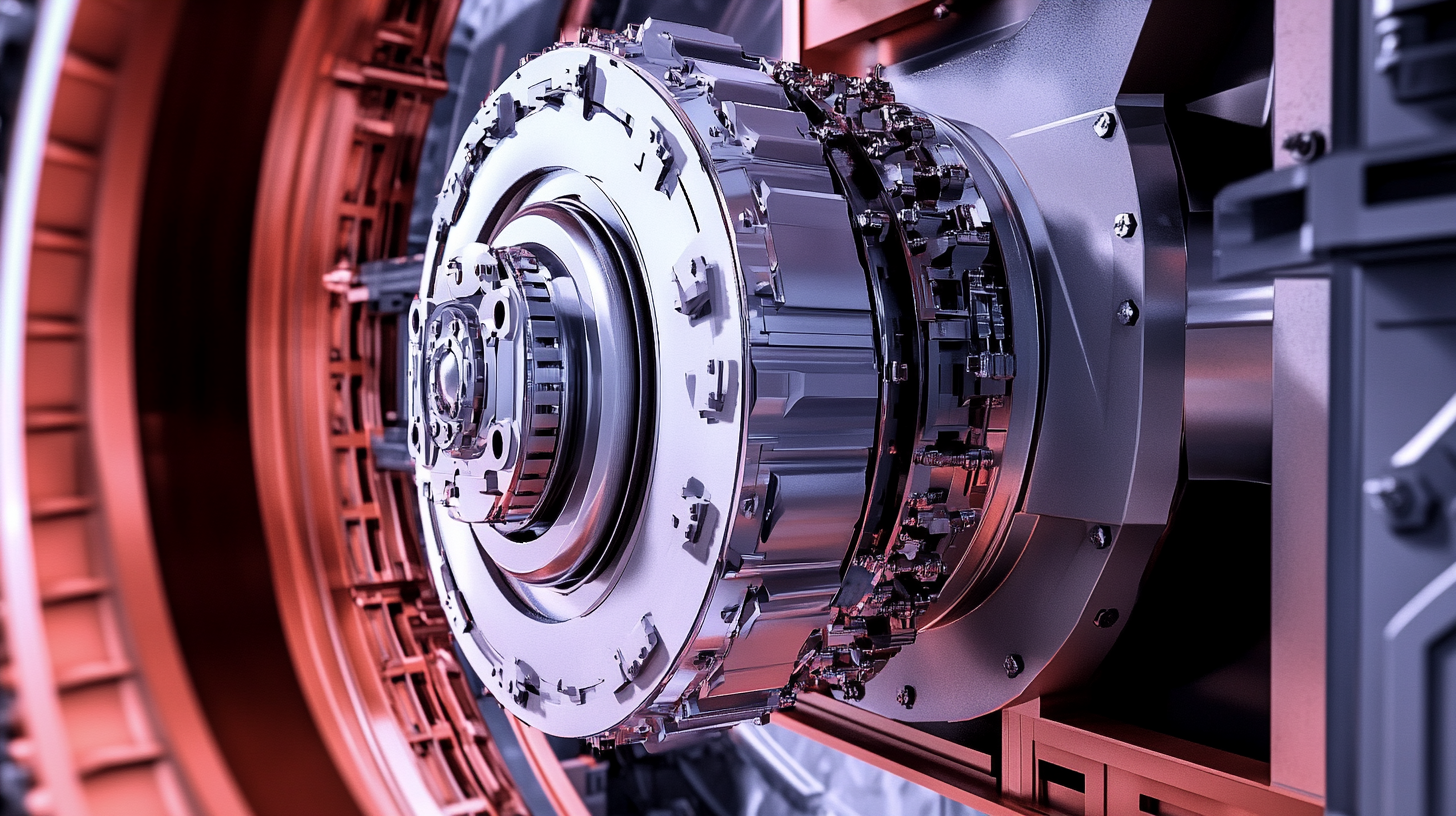

The countershaft bushing plays a crucial role in the performance of cone crushers, acting as a significant point of contact between the rotating parts and the main shaft. This small yet essential component helps stabilize the shaft's movement and reduces friction, resulting in smoother operation and improved efficiency. When the countershaft bushing is in optimal condition, it not only enhances the overall functionality of the cone crusher but also prolongs the lifespan of other critical components, reducing the frequency of repairs and replacements.

Effective maintenance of the countershaft bushing can lead to substantial savings in both operational costs and downtime. Regular inspections and timely replacements are key to ensuring that the bushing performs at its best. Additionally, using quality materials and proper lubrication techniques can mitigate wear and tear, preventing unanticipated failures. By prioritizing the maintenance of the countershaft bushing, operators can maximize the performance of their cone crushers, enabling them to achieve higher productivity without compromising on reliability.

Countershaft bushings are vital components in cone crushers, but poor maintenance can lead to significant operational challenges. A recent report from the Mining Industry Association highlights that inadequate lubrication and neglect can reduce the bushing lifespan by up to 70%. This often results in costly downtime, as businesses spend an average of $25,000 per hour in lost production due to equipment failures. Implementing a regular maintenance schedule, including inspection and lubrication routines, can mitigate these issues effectively.

Common problems associated with poorly maintained countershaft bushings include excessive wear, misalignment, and increased vibration, which can exacerbate operational inefficiencies. A study conducted by the Engineering Society of South Africa indicated that proactive maintenance strategies reduced unscheduled maintenance costs by nearly 30%. By understanding the common issues—such as improper installation and lack of regular stress testing—operators can adopt preventative measures that enhance performance and extend the life of their crushing equipment, ultimately maximizing savings and productivity.

Regular maintenance of countershaft bushings in cone crushers is crucial for ensuring their optimal performance and longevity. These components experience significant wear and tear due to their constant exposure to heavy loads and vibrations during operation. To enhance their lifespan, implementing effective maintenance practices is essential. One fundamental practice is conducting routine inspections, checking for signs of wear, cracks, or misalignment. By identifying issues early, you can prevent more severe damage and costly repairs.

Another important aspect of maintaining countershaft bushings is ensuring they are well-lubricated. Proper lubrication minimizes friction and heat generation, which can lead to premature failure. Using the appropriate type of lubricant and adhering to the recommended lubrication schedule is vital. Additionally, operators should consider the environmental conditions in which the crusher operates, as dust and contaminants can affect lubrication's effectiveness. Regularly cleaning the lubrication points and replacing old lubricant with fresh oil will keep the bushing functioning smoothly.

Finally, monitoring the performance of your cone crusher can provide insights into the condition of the countershaft bushings. Unusual noises, increased vibration, or changes in functionality can be early indicators of bushing issues. By staying proactive and adhering to these maintenance practices, operators can maximize savings and ensure the efficient operation of their cone crushers over time.

In the world of cone crushers, maintaining the countershaft bushing is critical for optimal performance and cost-efficiency. Recent industry data suggests that proper maintenance practices can lead to a reduction in unexpected downtimes by up to 30%, significantly enhancing productivity. Case studies from the mining sector highlight that regular inspections and timely replacements of countershaft bushings drastically decrease operational disruptions, allowing companies to maximize their output.

In the world of cone crushers, maintaining the countershaft bushing is critical for optimal performance and cost-efficiency. Recent industry data suggests that proper maintenance practices can lead to a reduction in unexpected downtimes by up to 30%, significantly enhancing productivity. Case studies from the mining sector highlight that regular inspections and timely replacements of countershaft bushings drastically decrease operational disruptions, allowing companies to maximize their output.

One compelling example comes from a leading construction aggregate company that implemented a predictive maintenance program. By leveraging data analytics, they were able to monitor the wear patterns of their countershaft bushings in real-time. As a result, they reduced maintenance costs by nearly 25% while increasing the lifespan of their equipment. This approach not only led to financial savings but also demonstrated how systematic maintenance strategies can drive long-term operational excellence in the industry. Such insights reinforce the importance of diligent maintenance protocols for sustaining high productivity levels and safeguarding capital investments in heavy machinery.

Regular maintenance of cone crushers, particularly focusing on components like the countershaft bushing, is crucial for maximizing operational efficiency and minimizing costs. A cost-benefit analysis reveals that proactive maintenance can significantly extend the lifespan of equipment, reducing the need for costly replacements and downtime. For instance, routine inspections and timely replacements of worn-out parts can prevent unexpected failures, allowing operators to maintain consistent production levels and avoid financial losses.

Investing in regular maintenance not only safeguards the equipment but also enhances overall productivity. As the cone crusher market is expected to grow with a CAGR of over 5.6% from 2025 to 2032, optimized operations become increasingly vital. By prioritizing effective maintenance strategies, companies can align their operational practices with market demands, ensuring they remain competitive. Enhanced maintenance practices lead to smoother operations, lower operational costs, and ultimately greater profits, highlighting the substantial benefits of a well-maintained cone crusher system.

This chart illustrates the cost savings associated with regular maintenance on countershaft bushings in cone crushers. The data shows the average maintenance costs compared to the potential costs of unexpected failures due to lack of maintenance. Regular maintenance results in significant savings and extended equipment life.