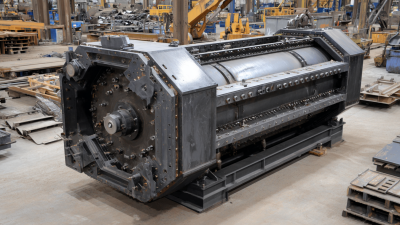

In the heavy machinery and mining industry, the durability and performance of equipment such as the jaw crusher are pivotal for operational efficiency. A significant component that directly affects the output and longevity of a jaw crusher is the Jaw Crusher Plate. According to a report from the Mining & Construction Equipment Manufacturers in 2021, the failure of wearing parts, including jaw plates, accounted for nearly 30% of all maintenance costs. Furthermore, optimal management of crusher components can lead to a reduction in downtime by up to 20%. Therefore, implementing strategies to maximize the lifespan of the Jaw Crusher Plate is not just beneficial but essential for companies aiming to enhance productivity and reduce overall costs. In this blog, we will explore seven essential tips that can help in extending the life and efficiency of this critical component, ensuring sustained performance in a competitive market.

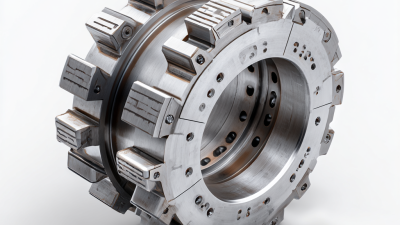

Understanding the different types of jaw crusher plates and their applications is crucial for optimizing performance and longevity in various mining and construction settings. Jaw crusher plates, generally made from a variety of materials such as manganese steel, chrome steel, and hybrid alloys, are designed to withstand the wear and tear of crushing processes. Manganese steel plates are the most popular due to their excellent work-hardening properties; they become more durable under stress, making them ideal for handling tough materials. According to a report by Allied Market Research, the global demand for jaw crushers is projected to increase, necessitating better wear-resistant materials.

To maximize the lifespan of your jaw crusher plates, one must consider regular inspections and maintenance as an essential practice. Ensuring proper alignment of the plates and using the appropriate feed size can significantly reduce wear. Additionally, choosing the right crushing settings for the application, such as the speed and stroke of the crusher, will enhance efficiency and prolong the service life of the plates. Utilizing advanced monitoring technologies can help operators gather crucial data on wear patterns, allowing for proactive changes and reduced downtime. By focusing on these strategies, facilities can ensure the optimal performance of their jaw crushers for years to come.

| Tip | Description | Plate Type | Application |

|---|---|---|---|

| Regular Inspection | Conduct frequent inspections to identify wear and tear. | Standard Jaw Plates | Primary crushing in hard rock applications. |

| Proper Lubrication | Ensure adequate lubrication to reduce friction and wear. | High Manganese Steel Plates | Used in various aggressive crushing environments. |

| Optimize Operating Settings | Adjust settings to maximize efficiency and reduce wear. | Toothed Jaw Plates | Ideal for reducing large aggregates to smaller sizes. |

| Choose the Right Material | Select materials that match the application requirements. | Chrome Moly Steel Plates | Common in applications where impact resistance is crucial. |

| Monitor Material Feed | Ensure consistent material feed to prevent blockages. | Jaw Plates with Different Profiles | Various applications depending on the jaw shape. |

| Avoid Overloading | Do not exceed the crusher's capacity to avoid damage. | Heavy Duty Jaw Plates | Used for crushing tough materials. |

| Regular Maintenance | Perform regular maintenance checks for longevity. | Custom Jaw Plates | Designed for specific materials and conditions. |

The wear rate of jaw crusher plates is influenced by several factors that vary across different industries. One primary factor is the hardness of the materials being crushed. Harder materials tend to cause more significant wear on the plates, leading to a shorter lifespan. For instance, in the mining sector where ores are often abrasive, the choice of plate material and its hardness can dramatically impact how long they last. Conversely, crushing softer materials, such as recycled concrete, may result in a slower wear rate.

Another critical element affecting wear rates is the operational parameters of the jaw crusher itself. The speed and stroke of the crusher can alter the degree of impact and compressive forces experienced by the plates. In industries where high throughput is essential, excessive wear can occur if the machine is not correctly calibrated. Furthermore, the design of the crushing chamber can also play a pivotal role in how effectively material is crushed and how wear is distributed across the jaw plates. Ensuring that the right parameters are in place is key to maximizing the longevity of these critical components.

When it comes to manufacturing durable jaw crusher plates, the choice of materials is critical to ensuring longevity and efficiency. Typically, high-quality manganese steel is favored for its exceptional strength and ductility. Manganese plays a pivotal role in the wear resistance of the plates, allowing them to withstand the high impact of crushing rocks and minerals. The incorporation of alloys, such as chrome and molybdenum, further enhances the toughness and hardness, making the plates more resilient to wear and tear.

In addition to manganese, other materials such as alloy steels and cast iron may also be utilized depending on the specific requirements of the operation. For instance, cast iron offers good performance in less demanding environments, while alloy steels can provide a balanced combination of hardness and ductility. The selection of the appropriate material ultimately stems from an assessment of the crushing application, ensuring that the plates are not only durable but also optimized for performance. By focusing on these key materials, operators can significantly enhance the operational lifespan of jaw crusher plates.

Regular maintenance of jaw crusher plates is essential for extending their lifespan and ensuring efficient operation. According to industry reports, neglecting maintenance can reduce the lifespan of a jaw crusher plate by up to 50%. One best practice is to conduct routine inspections to identify wear patterns early on. The National Stone Sand & Gravel Association (NSSGA) suggests that operators check for uneven wear, which can indicate misalignment or other issues that need to be addressed promptly.

Another critical aspect of maintenance involves the lubrication of the moving parts. Proper lubrication reduces friction between the jaw plates and other components, helping to prevent premature wear. The Mining and Metallurgy Research Institute states that using the manufacturer-recommended lubricant can enhance the longevity of the jaw crusher by up to 30%. Additionally, it’s vital to keep the crushing chamber free of any debris or foreign materials that can cause unnecessary wear. Implementing these best practices not only augments the crusher plate's lifespan but also contributes to overall operational efficiency.

When it comes to maximizing the longevity of jaw crusher plates, understanding cost-effectiveness is crucial. Investing in high-quality plates may seem like a larger upfront expense, but the long-term savings can be significant. High-quality materials are typically more durable, resisting wear and tear from continuous operation in harsh environments. This translates into fewer replacements and reduced maintenance costs over time, allowing businesses to allocate resources more efficiently.

Moreover, high-quality jaw crusher plates optimize performance, leading to increased productivity. When machinery operates at peak efficiency, it not only processes materials more effectively but also reduces energy consumption. In industries where operational costs can quickly spiral, the initial investment in superior plates can yield substantial savings and improved profit margins. Ultimately, weighing the cost of quality against the benefits it brings can make a compelling case for investing in premium jaw crusher plates.