In the realm of mining equipment, the fixed jaw plate plays a crucial role in the efficiency and functionality of crushing processes. As a key component of jaw crushers, the fixed jaw plate is designed to withstand the extreme conditions of mining operations, where durability and reliability are paramount. This essential guide delves into the various types of fixed jaw plates, outlining their unique features, benefits, and applications within the mining sector.

Understanding the different fixed jaw plate types is vital for equipment selection, maintenance, and optimization. From high manganese steel to modern composite materials, each variant brings specific advantages that can enhance the performance of crushing machinery. By exploring the intricacies of fixed jaw plates, operators and engineers alike can make informed decisions that lead to improved productivity and reduced downtime.

This guide aims to provide a comprehensive overview of fixed jaw plates, equipping readers with the knowledge necessary to leverage these components effectively within their mining operations. Whether you are involved in equipment design, maintenance, or operational management, grasping the significance of fixed jaw plates will empower you to optimize your mining processes and achieve greater economic efficiency.

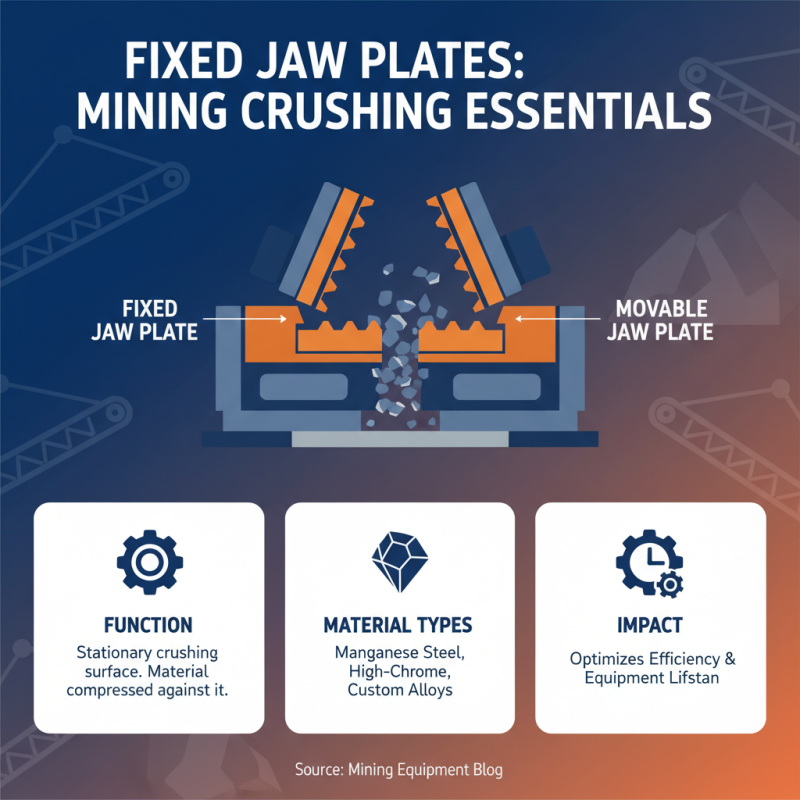

Fixed jaw plates are essential components in mining equipment, particularly in jaw crushers, where they serve as the stationary surface against which material is crushed. These plates are available in various types, each designed to meet the specific requirements of different mining operations. The choice of fixed jaw plate significantly impacts the efficiency and longevity of the equipment.

One of the most common types of fixed jaw plates is the smooth plate, which is typically used for crushing softer materials. This type offers an even surface that provides a uniform crushing action, reducing the chances of excessive wear. Conversely, the corrugated fixed jaw plate is designed for tougher applications, where it aids in the gripping and breaking of harder materials. Its ridged surface creates more friction and pressure during the crushing cycle, which can enhance the overall performance of the crushing process.

In addition to smooth and corrugated plates, there are custom-designed options that cater to specific mining needs. These plates may feature varying thicknesses, alloys, or surface treatments to optimize wear resistance and reduce downtime due to maintenance. Understanding the types of fixed jaw plates and their unique applications allows mining operations to select the most suitable option, ensuring optimal efficiency and reduced operational costs.

The material composition of fixed jaw plates is critical in determining their durability and overall performance in mining equipment. Typically, these plates are made from high manganese steel, which provides excellent wear resistance and toughness. When subjected to the rigorous demands of crushing operations, high manganese steel can work-harden, thereby increasing its surface hardness while maintaining ductility. According to a report from the Mining Equipment Manufacturers Association (MEMA), high manganese steel performs exceptionally well in environments with abrasive materials, which is a common occurrence in mining operations.

In addition to high manganese steel, some fixed jaw plates are fabricated using other alloyed steels or specialized composites that enhance their longevity in harsh conditions. Recent studies indicate that jaw plates constructed from a combination of alloys can significantly extend operational life by up to 30% compared to traditional materials. A report from the International Council on Mining and Metals (ICMM) highlights that increased durability not only reduces maintenance costs but also minimizes downtime, which is crucial for productivity in mining operations. As the industry continues to evolve, advancements in material science will further influence the design and effectiveness of fixed jaw plates in mining equipment.

This chart illustrates the durability ratings of various fixed jaw plate types used in mining equipment. The durability ratings are based on material composition and performance in harsh mining environments.

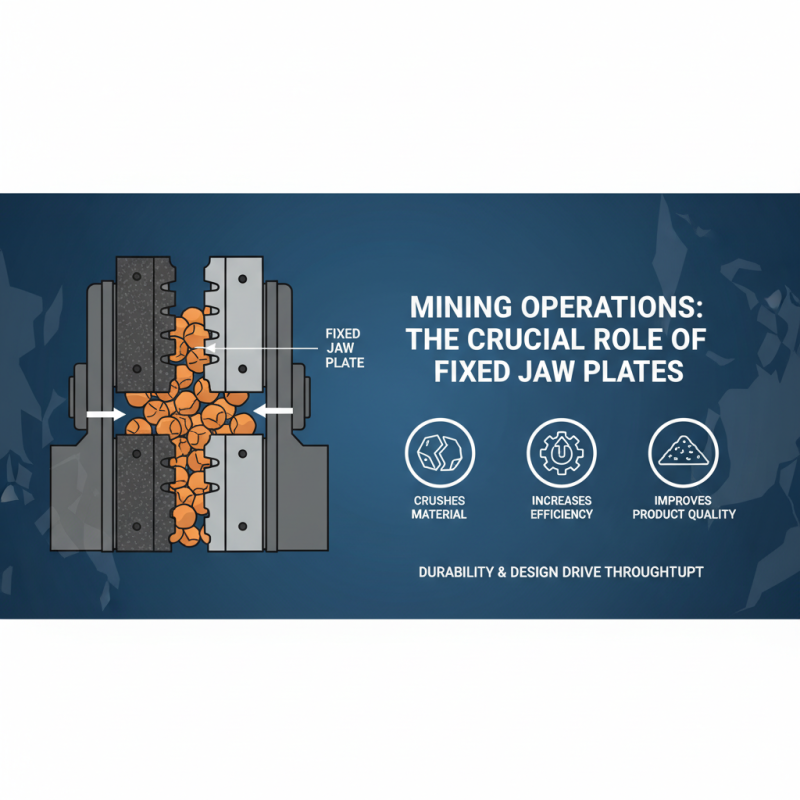

The design of fixed jaw plates plays a crucial role in enhancing the efficiency of crushing operations in the mining industry. According to a report by the International Journal of Mining and Mineral Engineering, optimal jaw plate design can increase the overall crushing efficiency by up to 30%. This efficiency is primarily influenced by factors such as the material composition of the jaw plates, their shape, and the angle of the jaws. A well-optimized fixed jaw plate can facilitate better material flow and reduce the energy consumption needed for crushing, thus improving operational productivity.

Moreover, the surface texture and wear resistance of fixed jaw plates significantly impact their longevity and functionality. Studies show that integrating advanced materials like manganese steel can lead to a reduction in wear rates, extending the life of the plates by approximately 20%. The design should also consider the crushing chamber's geometry, where a more intricate design may allow for a better grip on the material being crushed. As mining operations increasingly aim for sustainability and cost-effectiveness, investing in high-quality fixed jaw plate designs becomes imperative for achieving optimal crushing outcomes.

Fixed jaw plates play a crucial role in various mining operations, primarily serving as the stationary surface against which material is crushed. In aggregate production, for instance, these plates are integral to jaw crushers, where they help break down larger rocks into manageable sizes for further processing. The durability and design of fixed jaw plates significantly impact the overall efficiency of crushing operations, directly influencing the throughput and quality of the final product.

In mineral extraction, the application of fixed jaw plates extends to processing minerals like quartz and limestone. The robust construction of these plates allows them to withstand significant wear and tear, ensuring they maintain their functionality even under harsh conditions. Additionally, their design can be tailored to accommodate different mineral types, enhancing the adaptability of mining equipment. This versatility is essential for mining operations that require rapid changes in material processing, thus optimizing productivity and reducing downtime.

When it comes to maintaining fixed jaw plates in mining equipment, proactive maintenance is key to extending their lifespan and ensuring optimal performance. Regular inspections should be conducted to identify any signs of wear or damage. This includes checking for excessive wear on the surface of the jaw plates and ensuring that they are fitted properly within the frame. Any misalignment can lead to uneven wear, affecting both efficiency and durability.

Tips: Implement a routine cleaning schedule to remove debris and build-up around the jaw plates. This not only helps in identifying potential issues but also prevents premature wear caused by abrasive materials. Additionally, consider your operating conditions—highly abrasive materials can cause excessive wear, so adjustments to operational practices may be necessary.

Another practice to enhance the lifespan of fixed jaw plates is to ensure proper lubrication of the components. Lubrication minimizes friction and helps maintain a smooth operation, reducing wear and tear. Furthermore, training for operators on best practices, including load management and operational techniques, plays a crucial role in protecting jaw plates from unnecessary stress and damage. By focusing on these maintenance best practices, the longevity and reliability of fixed jaw plates can be significantly improved, leading to more efficient mining operations.