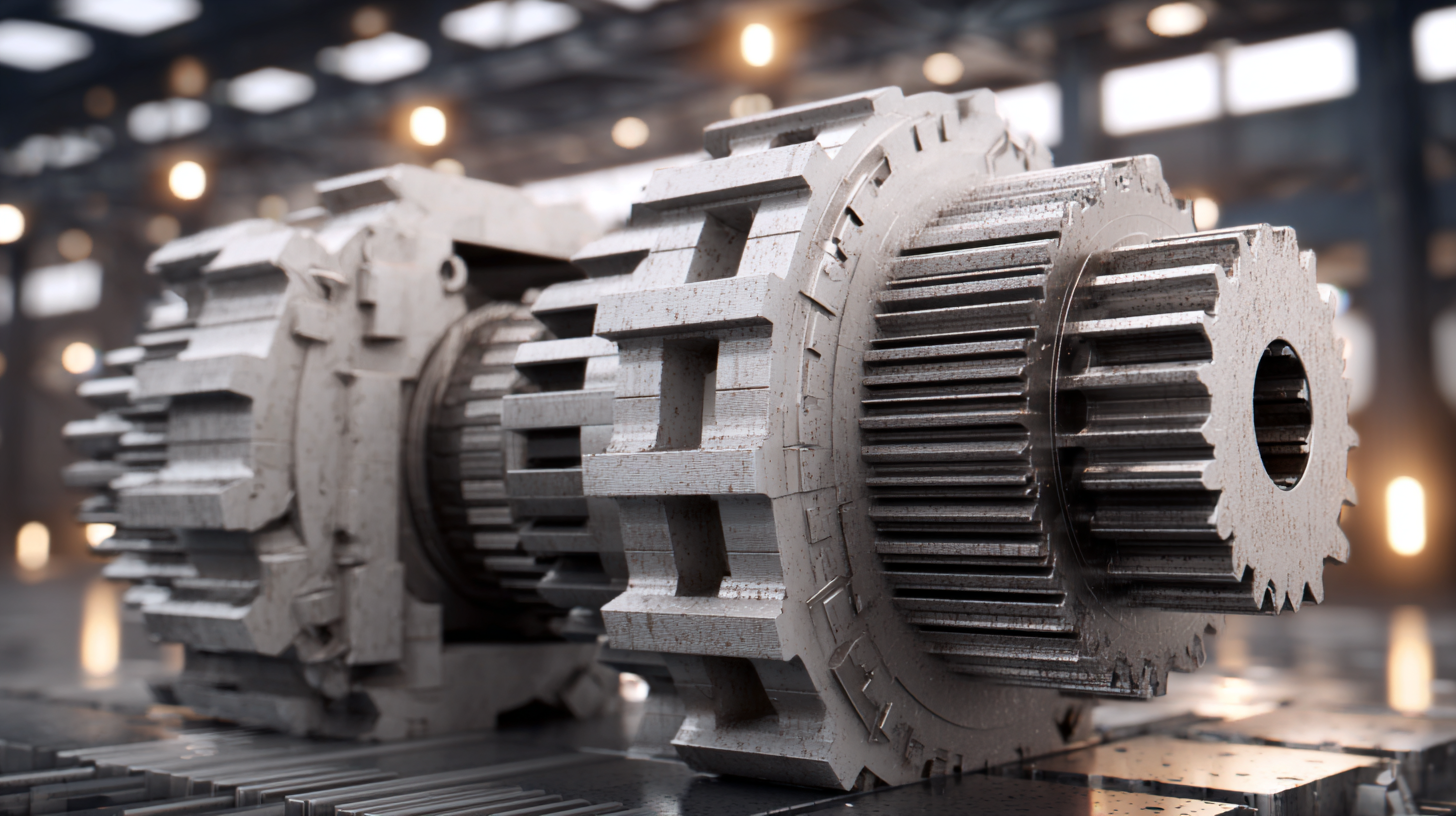

In the ever-evolving landscape of mining technology, the significance of Jaw Crusher Parts cannot be overstated. These essential components play a pivotal role in enhancing the efficiency and productivity of jaw crushers, which are fundamental to the crushing process in various mining operations. As the demand for minerals continues to rise, so does the need for robust and adaptable machinery. This blog will explore the diverse types of jaw crusher parts, their unique characteristics, and their applicable contexts within the mining sector. By shedding light on the latest advancements and innovations in jaw crusher parts, we aim to provide a comprehensive understanding of how these components are revolutionizing mining efficiency and paving the way for a more sustainable and productive future in the industry.

The evolution of jaw crusher components has seen a significant shift from traditional designs to more innovative and efficient solutions. Traditional jaw crushers, while effective, often come with limitations in terms of wear resistance and operational efficiency. The emergence of non-traditional manufacturers championing innovative thinking has led to the development of advanced jaw crusher parts that promise to enhance mining operations. These components are engineered with cutting-edge materials and designs, aimed at minimizing downtime and maximizing productivity in challenging conditions.

Recent advancements are not limited to just the components themselves; they encompass a broader rethinking of mining methodologies. Companies focused on designing effective new mining concepts are paving the way for modernizing crushing processes. By integrating contemporary technology into jaw crusher parts, the industry is witnessing a transformation that not only improves efficiency but also fosters sustainability. This forward-thinking approach is essential for meeting the growing demands of the mining sector, particularly in rapidly developing regions where mining solutions are becoming increasingly crucial.

The evolving landscape of mining technology emphasizes the critical role that jaw crusher parts play in enhancing mining performance. As operations seek greater efficiency, understanding the technical specifications of these components becomes crucial. High-performance jaw crushers equipped with advanced materials and innovative design features can significantly reduce downtime and operational costs. For instance, the use of wear-resistant alloys not only prolongs the lifespan of the equipment but also ensures that mining operations can maintain high productivity levels in demanding environments.

Tip: When selecting jaw crusher parts, always consider the operating conditions and the type of material being processed. This ensures that you choose components specifically designed for longevity and durability.

Moreover, integrating artificial intelligence into mining processes can lead to enhanced decision-making capabilities. By analyzing historical performance data and user interaction metrics, mining companies can optimize their equipment performance and reduce risks associated with mineral supply chains. This strategic application of technology not only fosters efficiency but also aligns with the broader objective of supporting sustainable energy transitions.

Tip: Leveraging data-driven insights allows companies to anticipate operational challenges and make informed adjustments proactively, ultimately driving higher efficiency and productivity in mining projects.

The advancement of materials engineering is paramount in enhancing the durability and efficiency of jaw crusher parts. Recent innovations in wear parts have set new industry standards, emphasizing the importance of reliability and high performance. By utilizing advanced materials and manufacturing techniques, including powder-based additive manufacturing, these new components are designed to withstand the extreme conditions that crushers face, thus improving their operational lifespan and productivity.

Effective maintenance coupled with state-of-the-art engineering solutions ensures that jaw crushers operate at optimal efficiency. Regular inspections and the integration of new service offerings are essential for maintaining the performance of crushing and screening operations. As the market for jaw crushers continues to grow, driven by increased demand for quality materials, the focus on engineering advancements and sustainable practices will become increasingly critical in revolutionizing mining efficiency. The synergy between innovative materials and efficient crushing methodologies will propel the industry toward a more productive and eco-friendly future.

| Part Name | Material | Durability (hrs) | Efficiency Improvement (%) | Application Area |

|---|---|---|---|---|

| Jaw Plate | High Carbon Steel | 2000 | 15 | Quarrying and Mining |

| Toggle Plate | Alloy Steel | 1800 | 10 | Construction |

| Side Plate | Manganese Steel | 2200 | 12 | Recycling |

| Cheek Plate | High Manganese Steel | 2500 | 20 | Mining |

| Bearing | Bronze | 1500 | 8 | Heavy Machinery |

In the realm of mining, jaw crushers play a crucial role in breaking down materials efficiently. As the industry evolves, the integration of advanced technology into jaw crusher parts has emerged as a game changer. Modern innovations focus on enhancing the lifespan and reliability of these components, ensuring that mining operations run smoothly and productively. By utilizing cutting-edge materials and smart design, manufacturers are developing parts that withstand the rigors of heavy use, ultimately reducing downtime and maintenance costs.

The importance of technology extends beyond mere durability; it encompasses adaptive features that optimize performance in various conditions. For instance, digital sensors and monitoring systems can provide real-time data on the health of jaw crusher parts, allowing for timely interventions before minor issues escalate. This proactive approach not only enhances operational efficiency but also supports sustainability efforts by minimizing resource waste and extending the lifecycle of equipment. As mining continues to embrace these technological advancements, the future of jaw crusher parts stands to revolutionize industry standards, paving the way for more efficient and reliable mining processes.

The evolution of jaw crusher parts is set to transform the mining industry significantly, focusing on

smart features and

automation integration. As mining operations strive for

increased efficiency and

lower operational costs, the integration of advanced technologies

into jaw crushers becomes vital.

Smart features, such as predictive maintenance systems and real-time performance monitoring,

enable operators to anticipate failures before they occur, reducing downtime and enhancing productivity.

Such innovations not only streamline maintenance schedules but also extend the

lifespan of the equipment.

Automation is another critical trend shaping the future of jaw crusher components. By incorporating automated systems,

mines can achieve higher levels of precision and control in their crushing processes.

Features like automated adjustment of the crushing gap and robotic controls allow for optimal material handling and

reduced human error. Furthermore, the use of

artificial intelligence in analyzing operational data empowers operators to make

informed decisions quickly, adapting to changing conditions in the mining environment. As these smart technologies

continue to evolve, they promise a future where jaw crushers are not only more efficient but also adaptive to

the growing demands of the mining industry.

Automation is another critical trend shaping the future of jaw crusher components. By incorporating automated systems,

mines can achieve higher levels of precision and control in their crushing processes.

Features like automated adjustment of the crushing gap and robotic controls allow for optimal material handling and

reduced human error. Furthermore, the use of

artificial intelligence in analyzing operational data empowers operators to make

informed decisions quickly, adapting to changing conditions in the mining environment. As these smart technologies

continue to evolve, they promise a future where jaw crushers are not only more efficient but also adaptive to

the growing demands of the mining industry.