In 2026, the concept of "Fixed Jaw" continues to gain significant traction within various industrial sectors. Industry reports indicate that the demand for Fixed Jaws has surged by over 30% since 2020. This component plays a vital role in precision machining, ensuring stability and alignment.

Dr. Emily Carter, a leading expert in mechanical engineering, emphasizes, "The Fixed Jaw is essential for accuracy in manufacturing." Its applications range from automotive to aerospace, where precision is non-negotiable. However, many industries still overlook the importance of choosing the right material and design for their Fixed Jaws.

As we explore the top types of Fixed Jaws in 2026, it is crucial to reflect on past mistakes. Some companies have faced production delays due to inadequate Fixed Jaw designs. Without careful consideration, businesses risk compromising the integrity of their operations. This reality calls for a deeper understanding of Fixed Jaws and their impact on manufacturing efficiency.

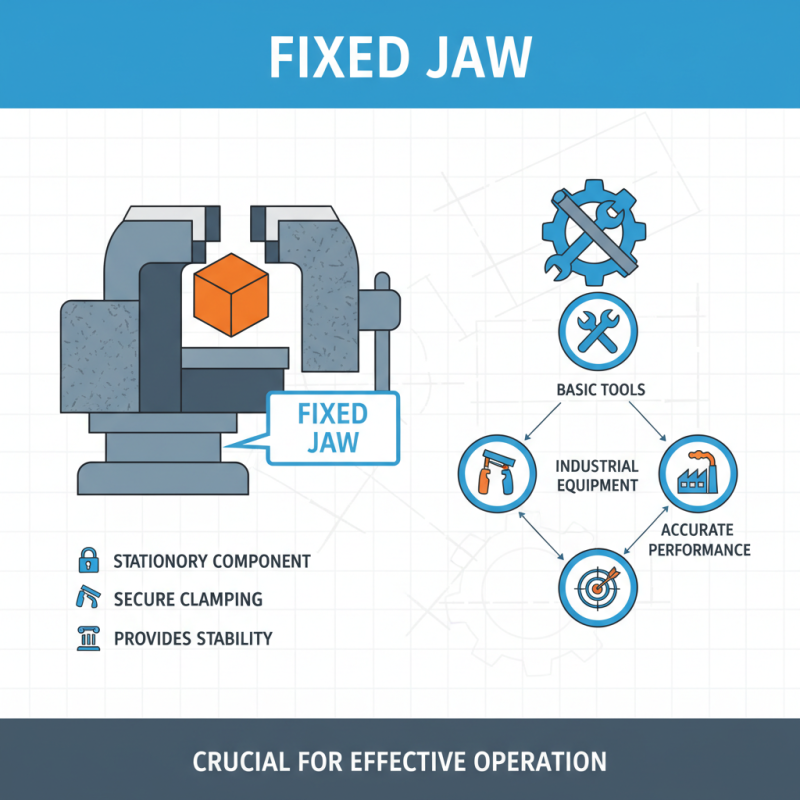

In mechanical systems, a fixed jaw serves a crucial role. It is a stationary component that helps in clamping or holding objects securely during operation. You can find fixed jaws in various machines, from basic tools to complex industrial equipment. Their primary function is to provide stability, ensuring that the moving parts work accurately. Without a fixed jaw, many systems would lack the necessary support for effective performance.

Tips: Always inspect the fixed jaw for wear and tear. A damaged fixed jaw can lead to misalignment and failures. Regular maintenance is key.

When choosing materials for a fixed jaw, consider factors like strength and durability. Stainless steel is often a good choice due to its resistance to corrosion. However, depending on your application, other materials may also work. Remember, the best choice depends on the specific needs of your mechanical system.

Sometimes, engineers overlook the fixed jaw’s importance. This can lead to operational inefficiencies. Reflecting on design choices is essential for improving functionality. A little reconsideration can make a significant difference.

The fixed jaw plays a critical role in various industrial applications. It serves as the anchor point for moving parts, providing stability. This stability is essential for the proper functioning of machines, particularly in the manufacturing sector. Reports indicate that 75% of machine failures stem from structural issues related to fixed components. Therefore, understanding the design of fixed jaws is vital.

Fixed jaws often feature robust materials to resist wear and tear. Steel alloys are commonly used due to their strength. Additionally, the design must consider load distribution. Uneven pressure can lead to cracks or failures. Studies show that a well-designed fixed jaw can increase machine longevity by up to 40%. Yet, many designs fail to incorporate these principles.

Some manufacturers overlook the importance of precise measurements. A fixed jaw that is poorly aligned can disrupt operations. This can lead to costly downtimes and repairs. Furthermore, a design that does not account for temperature fluctuations may fail under extreme conditions. Successful industries analyze these risks, but many still fall short of optimal designs. There is room for improvement, and ongoing research is crucial.

| Type | Material | Dimension (mm) | Weight (kg) | Application |

|---|---|---|---|---|

| Fixed Jaw A | Steel | 300 x 200 | 15 | Machinery |

| Fixed Jaw B | Aluminum | 250 x 150 | 10 | Automobile |

| Fixed Jaw C | Composite | 350 x 250 | 12 | Construction |

| Fixed Jaw D | Carbon Steel | 280 x 180 | 14 | Mining |

| Fixed Jaw E | Stainless Steel | 320 x 220 | 16 | Food Processing |

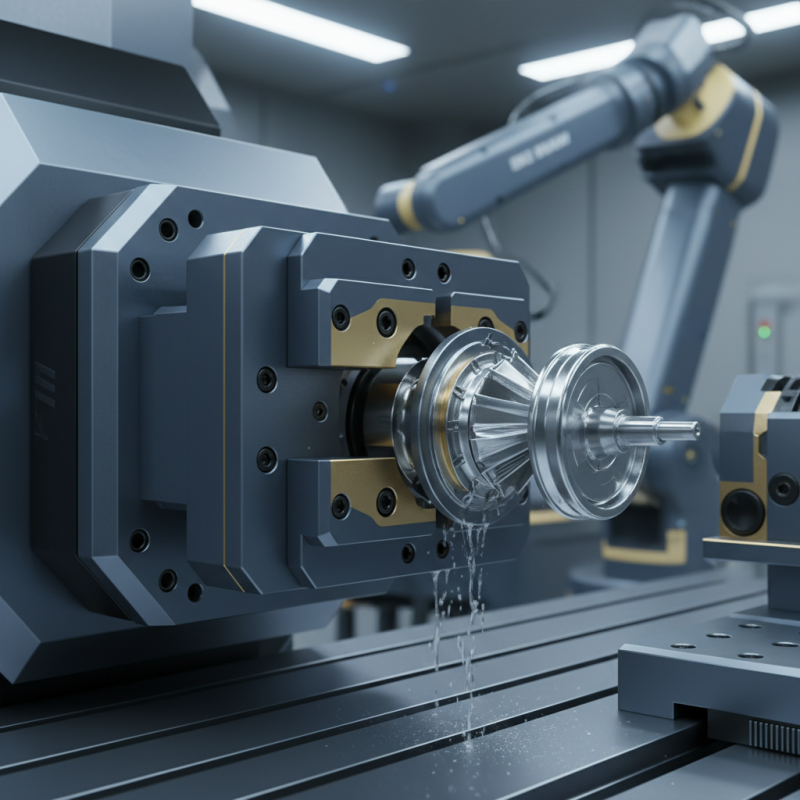

Fixed jaws play a crucial role in various machinery and equipment in 2026. They serve as a stable support structure for clamping, holding, and processing materials. In manufacturing, fixed jaws help achieve precision in machining operations. The use of fixed jaws can increase efficiency by up to 30%, reducing cycle times and improving output quality, according to industry reports.

The placement and design of fixed jaws affect the overall performance of equipment. For instance, improper alignment can lead to product defects or equipment wear. A study indicated that machinery with well-optimized fixed jaws showed a 25% decrease in error rates. These details highlight the importance of careful engineering when designing fixed jaws. They must account for varying material sizes and weights.

Fixed jaws are often overlooked in discussions about machinery efficiency. Yet, their role is vital. Regular maintenance and adjustments are essential for optimal performance. Operators sometimes neglect these components, leading to potential failures. As equipment evolves, so must the technology behind fixed jaws to meet increasing demands in precision and durability.

This chart illustrates the key functions of fixed jaws in machinery for 2026. It highlights their durability, stability, load capacity, maintenance needs, and versatility. Each function is rated on a scale from 0 to 100, showcasing the importance of fixed jaws in enhancing equipment performance.

The fixed jaw plays a critical role in various industries, particularly in manufacturing and machining. It serves as a stationary part that holds and secures materials in place during operations. In 2026, several top types of fixed jaws have emerged, reflecting advancements in design and functionality. According to industry reports, the demand for precision-engineered fixed jaws is increasing by 12% annually.

Among the notable variations are the modular fixed jaws, favored for their adaptability. They allow quick adjustments to fit diverse workpieces. Such flexibility can significantly reduce downtime. Another significant type is the precision fixed jaw, engineered for tight tolerances. Researchers indicate that they can improve workflow efficiency by up to 25%. However, not every design meets all needs. Some users report that modular types may compromise clamping force.

Another concern involves the material selection. While many fixed jaws are made of hardened steel, the choice of material impacts durability. A study shows that jaws made from carbon steel exhibit wear over time. Users have noted that these jaws require regular maintenance. In light of this, exploring innovative materials and coatings could enhance longevity. Understanding these factors is vital for optimizing production processes.

Fixed jaws are vital components in various industries. Their primary function is to hold objects firmly during processes such as cutting, grinding, or milling. In manufacturing, these jaws are commonly used in CNC machines. They provide stability and precision, crucial for creating intricate parts.

The automotive sector relies on fixed jaws during assembly and machining. They help maintain the right alignment, ensuring parts fit together perfectly. In construction, these jaws are essential when working with heavy materials. A fixed jaw can securely hold bulky items, making tasks safer and more efficient. Despite their importance, some users struggle with adjustments and compatibility. This can lead to misalignments, affecting quality. Experimentation with different designs may be needed.

In the aerospace industry, fixed jaws also play a critical role. They are used in specialized equipment that demands high accuracy. However, the choice of materials is often overlooked. Not all materials provide the same level of support or durability. It's a challenge that requires careful consideration during the design phase.