In the ever-evolving landscape of the global mining industry, sourcing high-quality components such as

Mining Machinery Jaw Plates is paramount for operational efficiency and longevity of equipment.

According to a recent report by Global Mining Review, the global mining machinery market is projected to reach

USD 192 billion by 2025, with a significant portion attributed to the demand for durable and reliable

jaw plates used in crushers. These components are crucial for ensuring optimal performance and reducing downtime,

which directly impacts productivity and profitability. As miners and contractors increasingly prioritize

sustainability and cost-effectiveness, understanding the essential factors in sourcing these critical parts becomes indispensable.

This blog will explore the five vital considerations for procuring Mining Machinery Jaw Plates from a global supply chain,

ensuring that your operations remain competitive in this dynamic industry.

In the ever-evolving landscape of the global mining industry, sourcing high-quality components such as

Mining Machinery Jaw Plates is paramount for operational efficiency and longevity of equipment.

According to a recent report by Global Mining Review, the global mining machinery market is projected to reach

USD 192 billion by 2025, with a significant portion attributed to the demand for durable and reliable

jaw plates used in crushers. These components are crucial for ensuring optimal performance and reducing downtime,

which directly impacts productivity and profitability. As miners and contractors increasingly prioritize

sustainability and cost-effectiveness, understanding the essential factors in sourcing these critical parts becomes indispensable.

This blog will explore the five vital considerations for procuring Mining Machinery Jaw Plates from a global supply chain,

ensuring that your operations remain competitive in this dynamic industry.

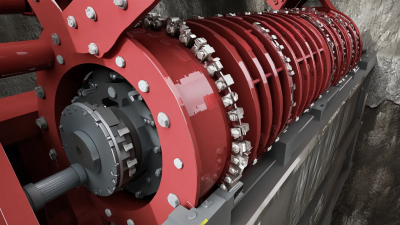

When sourcing jaw plates for mining machinery, assessing global suppliers requires a keen eye on several key criteria. First and foremost, the quality of materials used in jaw plate production is critical. Durability and resistance to wear are paramount, as jaw plates operate under high-stress conditions. Suppliers should offer certification of their materials and demonstrate a commitment to high manufacturing standards, ensuring that their offerings can withstand the rigors of mining operations.

Another essential factor is the supplier's track record in the market. Evaluating their experience and reputation among previous clients can provide valuable insights into reliability and performance. Reviews and testimonials can highlight a supplier's customer service, consistency in delivery times, and responsiveness to issues that may arise. Additionally, understanding the range of jaw plate designs offered is important, as different mining operations may require customized solutions tailored to specific equipment and environments. This flexibility demonstrates a supplier’s ability to adapt to the unique challenges presented by varying mining contexts.

When sourcing jaw plates for mining machinery, analyzing cost-effectiveness across diverse markets is crucial. The global jaw crushers market, projected to grow from USD 2.8 billion in 2024 at a CAGR of 4.2% until 2034, highlights the competitive landscape and the importance of strategic sourcing. Different markets offer varying costs and qualities, making it essential to evaluate your options carefully.

**Tip:** Always conduct a thorough market analysis to identify suppliers that offer high-quality jaw plates at competitive prices. Look for manufacturers with a reputation for durability, as this can significantly reduce long-term costs related to maintenance and replacements.

**Tip:** Consider the logistical aspects of sourcing. Shipping costs, import duties, and delivery times can impact overall expenses. Selecting suppliers closer to your operation might minimize these costs and ensure timely procurement.

By focusing on these factors and leveraging market insights, businesses can enhance their sourcing strategies to achieve optimal efficiency and cost-effectiveness in their mining operations.

When sourcing mining machinery jaw plates globally, one of the foremost considerations is the quality of the materials used. Different countries have varying standards and specifications for the materials that should be utilized in producing jaw plates. For instance, high-carbon steel and manganese alloys are commonly favored in countries with a robust mining sector due to their excellent wear resistance and strength. Comparing these standards can help ensure that the jaw plates purchased will withstand the harsh conditions of mining operations.

Moreover, understanding local production practices and quality assurance measures is crucial. In regions with stringent manufacturing regulations, such as Europe or North America, suppliers often adhere to higher quality certifications, ensuring that their jaw plates not only meet but exceed industry standards. Meanwhile, sourcing from regions with less oversight might require additional diligence, as the materials used could vary significantly in quality. By thoroughly investigating the material specifications and the credibility of suppliers across different regions, companies can make more informed decisions that align with their operational needs and budget constraints.

In the mining industry, the sourcing of essential components like jaw plates cannot be taken lightly, especially when considering lead times and logistics. The demand for efficient and timely delivery is paramount, not only to maintain operational flow but also to meet the rising challenges associated with sustainability in the supply chain. As the world moves towards greener technologies, the pressure on logistics networks to adapt and deliver sustainably sourced materials has intensified.

The integration of electric vehicle technologies is reshaping global markets, emphasizing the need for logistics systems that are efficient and environmentally conscious. Suppliers must be vigilant in their selection processes, ensuring that their logistics partners not only meet delivery deadlines but also align with sustainability goals. Factors such as transportation methods, geographical considerations, and warehousing capabilities play critical roles in the sourcing of jaw plates, ultimately impacting both the operational capacity of mining companies and their environmental footprint. Addressing these challenges requires a collaborative approach, where all stakeholders prioritize timely and responsible practices in their supply chain strategies.

When sourcing mining machinery jaw plates globally, supplier reputation stands as a crucial pillar in ensuring quality and reliability. Trustworthiness in the jaw plates supply chain not only impacts operational efficiency but also influences safety standards in mining operations. It is essential to conduct thorough research on potential suppliers, delving into their history, client reviews, and industry standing.

Tip: Start by checking the supplier's online presence and certifications. Look for feedback from previous clients to gauge their reliability and service consistency. A well-established supplier will have a transparent track record that speaks volumes about their operational integrity.

Moreover, establishing direct communication with suppliers can provide insights into their business practices and commitment to quality. Assess whether they adhere to international standards and regulations in manufacturing jaw plates. Understanding their supply chain logistics can also reveal how they manage quality control under various conditions.

Tip: Engage in dialogue with potential suppliers about their processes and standards. This not only builds a relationship but also allows you to ask specific questions about their commitment to quality assurance and delivery timelines.