In the competitive landscape of aggregate production, the efficiency and effectiveness of processing equipment play a crucial role in determining overall output and operational costs. Among the most critical components of a cone crusher, the cone crusher concave stands out as a key player in optimizing performance. According to industry expert Mark Anderson, “The design and condition of a cone crusher concave directly influence the particle size and shape, which are vital for meeting product specifications.” This underscores the significance of investing in high-quality concaves to enhance the crushing process.

The proper selection and maintenance of cone crusher concaves can lead to significant improvements in production efficiency. As aggregates are subjected to various forces within the crushing chamber, the concave’s profile and material composition determine how effectively the crusher can break down materials. When optimized, these components not only facilitate a more uniform product size distribution but also reduce operational wear, resulting in lower downtime and maintenance costs.

As the demand for quality aggregates continues to rise, understanding the intricate relationship between cone crusher concaves and overall productivity becomes increasingly essential. This article delves into the key insights and data surrounding the impact of concaves on aggregate production efficiency, providing valuable guidance for industry professionals seeking to maximize their output and profitability.

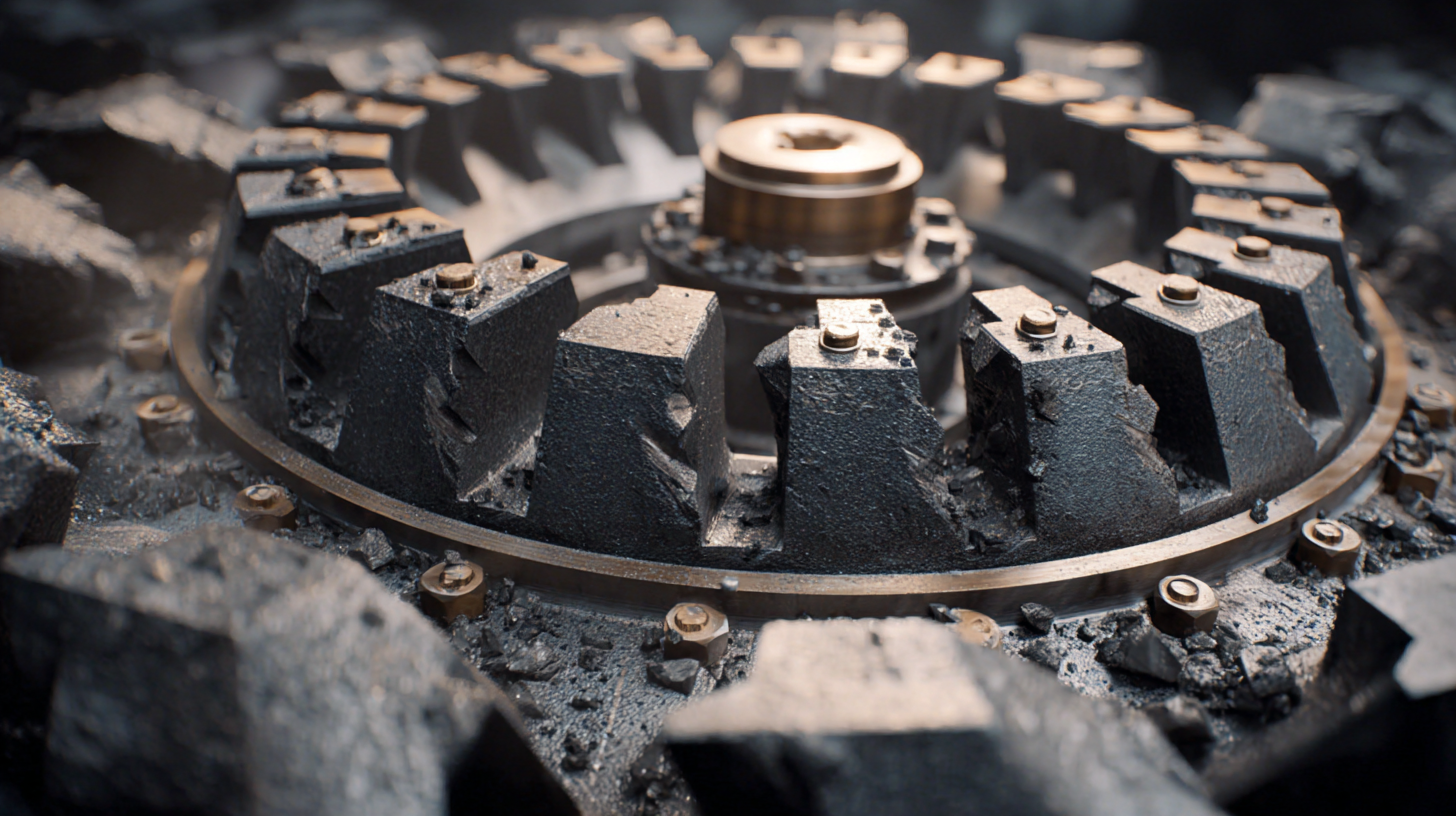

The role of cone crusher concaves in aggregate production efficiency is paramount, as these components directly influence the size reduction process. Concaves create a critical interaction with the mantle, shaping the material as it is crushed and ensuring a uniform size distribution. This uniformity not only enhances the quality of the final product but also improves productivity by minimizing the amount of oversize material, which can lead to costly reprocessing.

Moreover, the design and wear characteristics of cone crusher concaves can significantly impact overall operational cost. High-quality concaves increase the lifespan of the components, reducing downtime and maintenance expenses. By optimizing the concave profile based on the specific material being processed, producers can achieve higher throughput rates while maintaining consistent performance. Ultimately, investing in well-designed cone crusher concaves is a strategic approach to maximizing aggregate production efficiency, driving profitability, and meeting increasing market demands.

The performance of cone crusher concaves is crucial in achieving optimal aggregate production efficiency. One of the primary factors influencing this performance is the material composition of the concaves. According to a report by the International Council on Mining and Metals (ICMM), the use of high-quality alloy steel can enhance wear resistance, contributing to an increase in service life by up to 25%. This extended durability is essential for maintaining consistent output levels and minimizing downtime, which is critical in competitive aggregate markets.

Another key factor is the design of the concaves themselves. Variations in the profile and shape can significantly affect the crushing chamber's performance. Research by the Colorado School of Mines indicates that adjusting the concave profile can lead to a 15% increase in throughput. Furthermore, the angle of the concaves plays a pivotal role in determining the size and shape of the crushed material, which directly impacts the quality of the final product. By optimizing these aspects, operators can improve their production efficiency and meet the rising demands of the aggregate industry more effectively.

This chart illustrates the performance impact of various factors on cone crusher concaves, highlighting the significance of optimizing these parameters for efficient aggregate production.

Cone crusher concaves play a critical role in enhancing aggregate production efficiency. The wear rates and lifespan of these components are vital statistics for quarry operators aiming to maximize productivity. Typically, concaves undergo significant wear as they come into contact with aggregates, leading to reduced performance over time. Understanding the average lifespan of these parts helps in planning maintenance schedules and minimizing downtime. Studies indicate that high-quality concaves can significantly extend the service life, directly impacting the operational efficiency and cost-effectiveness of aggregate production.

Recent advancements in cone crusher technology have introduced next-generation models designed to optimize performance and reduce wear. The new models boast features that enhance the durability of concaves, allowing for longer service intervals and improved overall efficiency. With these innovations, operators can expect to see lower wear rates, resulting in fewer replacements and operational disruptions. As the industry continues to evolve, the importance of using efficient and durable concaves remains paramount for achieving peak production levels in mining and aggregates applications.

The design of concaves in cone crushers plays a pivotal role in determining the particle size distribution of aggregates. Concaves are the stationary components that align with the crushing head to reduce the size of the material being processed. Various geometric configurations and materials can significantly affect the efficiency and effectiveness of the crushing process. A well-designed concave optimizes the crushing circuit, ensuring that the aggregate produced meets specific gradation requirements for different applications.

Moreover, the impact of concave design extends beyond mere size reduction; it influences the overall shape and stability of the particles. Different profiles of concaves can produce a range of outcomes in terms of angularity and surface texture, which are critical for ensuring optimal performance in construction and other applications. By analyzing data from production processes, it becomes clear that selecting an appropriate concave design not only enhances crushing efficiency but also improves the quality of the final aggregate product, leading to better performance in concrete mixing and other uses. Thus, understanding the intricacies of concave design is essential for operators looking to maximize production efficiency and product consistency.

Optimizing cone crusher concave configurations is crucial for enhancing aggregate production efficiency. A thorough cost-benefit analysis can illustrate how strategic modifications to concave design lead to significant operational savings. By selecting the appropriate concave profiles, operators can maximize material throughput while minimizing wear and tear on the equipment, which translates to lower maintenance costs and extended life cycles for both the crushers and the consumables involved.

Optimizing cone crusher concave configurations is crucial for enhancing aggregate production efficiency. A thorough cost-benefit analysis can illustrate how strategic modifications to concave design lead to significant operational savings. By selecting the appropriate concave profiles, operators can maximize material throughput while minimizing wear and tear on the equipment, which translates to lower maintenance costs and extended life cycles for both the crushers and the consumables involved.

Tips for optimizing concave configurations include assessing the nature of the material being crushed and adjusting the settings accordingly. Regularly reviewing the wear patterns on concaves can provide insight into their performance, allowing for timely adjustments that prevent unnecessary loss of productivity.

Additionally, employing a combination of shallow and steep concaves can create optimal results across different production cycles, catering to both primary and secondary crushing needs.

Moreover, investing in high-quality concave materials can yield a better return in the long run. While initial costs may be higher, improved durability and performance often result in lower total cost of ownership, making it a wise decision for companies focusing on sustainable growth and efficiency in aggregate production.