In the world of aggregate production, understanding the intricacies of cone crusher parts is paramount for achieving optimal performance and longevity of the equipment. As highlighted by industry expert John Smith, “Proper maintenance and knowledge of cone crusher parts are critical for maximizing efficiency and reducing downtime.” This statement encapsulates the essence of using these essential components correctly and maintaining them effectively to ensure that operations run smoothly.

Cone crushers are fundamental in various sectors, including construction and mining, where they process materials with tremendous efficiency. However, their performance is heavily reliant on the condition and quality of the cone crusher parts. Regular inspection and timely replacement of worn-out components can significantly enhance operational productivity and extend the lifespan of the machinery. The importance of being well-versed in the function and maintenance of these parts cannot be overstated, as it not only meets production demands but also safeguards one’s investment in heavy machinery.

In this article, we delve into practical tips for maintaining and optimizing cone crusher parts, ensuring that users can make informed decisions that boost their operational effectiveness while minimizing unnecessary costs. Through careful attention to these vital components, businesses can stay competitive in a demanding market landscape.

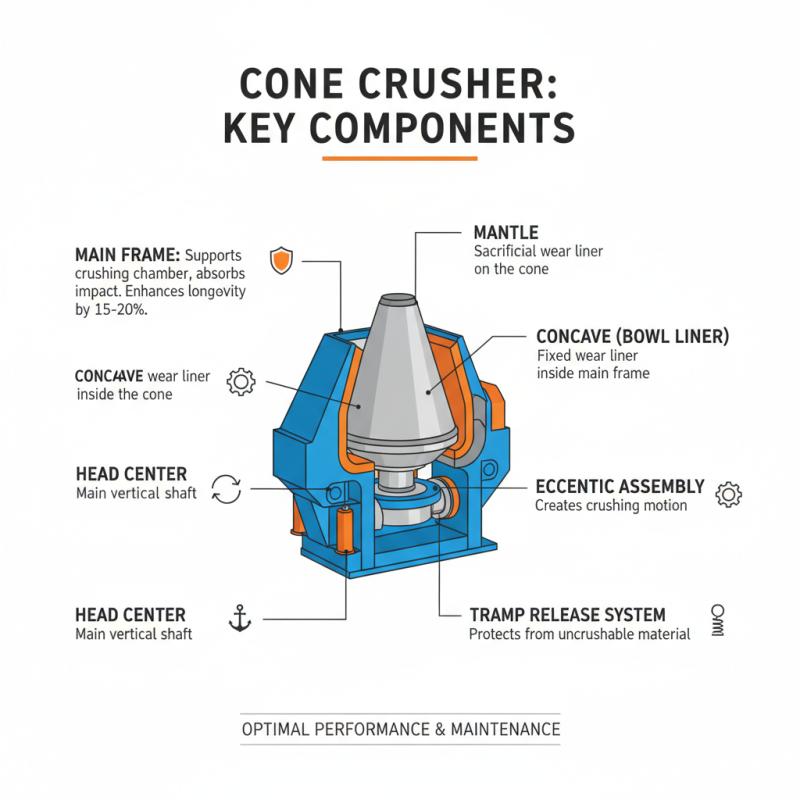

Understanding the core components of a cone crusher is essential for optimal performance and maintenance. At the heart of the cone crusher lies its main frame, which supports the crushing chamber and provides structural integrity. A robust main frame is vital, as it absorbs the heavy impacts generated during the crushing process. According to industry reports, a well-built main frame enhances overall crusher longevity by 15-20%.

Another crucial component is the mantle, which is the moving part of the cone crusher that crushes the material against the stationary bowl liner. The interaction between the mantle and the bowl liner is fundamental, as it directly influences the size and shape of the crushed material. Research has shown that the right alloy composition in these parts can lead to a reduction in wear rates by up to 30%, significantly lowering maintenance costs and downtime. Furthermore, regular inspections of the mantle and bowl liner can help in identifying wear patterns early, ensuring the optimization of performance over time.

Finally, the hydraulic system plays a pivotal role in maintaining operational efficiency. It not only enables adjustment of the crusher's setting but also provides circuit overload protection. Industry data indicates that over 50% of operational issues are linked to hydraulic system failures, underlining the importance of regular maintenance and monitoring to ensure smooth operation and prevent costly repairs.

Regular maintenance of cone crusher parts is crucial to ensure optimal performance and longevity of the equipment. Routine checks help identify wear and tear before they escalate into significant issues that could lead to costly repairs or unplanned downtime. Inspecting components such as the mantle, bowl liner, and spacing elements can prevent premature failure and enhance the efficiency of the crushing process. By maintaining a consistent maintenance schedule, operators can guarantee that each part operates within its specifications, promoting better productivity.

Additionally, regular maintenance helps in maintaining the quality of the crushed material. Components that are not frequently inspected can lead to uneven wear, resulting in substandard processing and potentially damaging downstream equipment. Implementing a proactive maintenance strategy fosters a safer working environment, as it minimizes the risk of mechanical failures that can pose hazards to operators. In summary, the importance of regular maintenance for cone crusher parts cannot be overstated, as it directly impacts performance, safety, and operational costs.

Inspecting and replacing worn cone crusher parts is critical for maintaining optimal performance and prolonging the lifespan of mining and aggregate processing equipment. Regular inspections should focus on key components such as the mantle, bowl liner, and the main shaft. According to industry reports, damaged or worn parts can significantly reduce production efficiency by up to 30%, highlighting the importance of proactive maintenance practices. During inspections, operators should look for signs of excessive wear, including cracks, gouges, and abnormal vibrations, which indicate that immediate intervention may be necessary.

When it comes to replacing worn parts, maintaining precise specifications is crucial. Proper fitment ensures that the cone crusher operates effectively, reducing the risk of breakdowns and enhancing productivity. Industry data suggests that using parts with inadequate tolerances can lead to higher operational costs and increased downtime, ultimately affecting project timelines. Additionally, operators are encouraged to implement a systematic wear monitoring program, utilizing tools such as ultrasonic thickness gauges to track wear progression. By integrating these practices, facilities can optimize their cone crusher performance, reducing unnecessary maintenance costs and downtime associated with unplanned repairs.

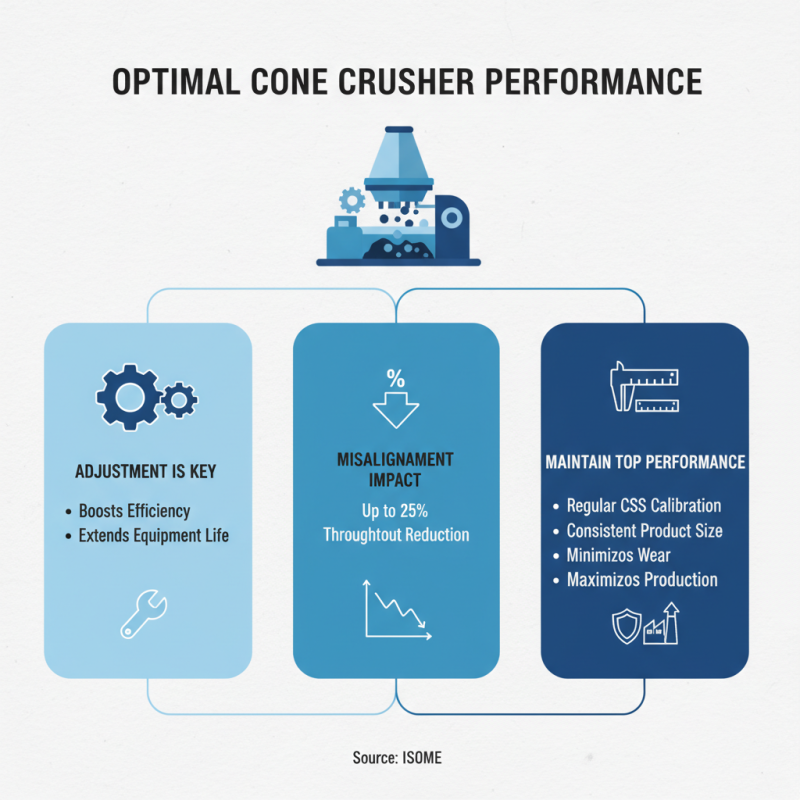

Proper adjustment of a cone crusher is pivotal in achieving optimal performance and extending the life of the equipment. According to a study by the International Society of Mining and Mineral Engineering, even a minor misalignment in the cone's setting can lead to a reduction in throughput by up to 25%. This indicates that meticulous attention to the adjustment settings can significantly enhance operational efficiency. Regularly checking and calibrating the closed-side setting (CSS) ensures that the material is crushed to the desired size, which not only minimizes the wear on liner materials but also maximizes production rates.

Moreover, adjusting the cone crusher's operational parameters, such as the stroke length and speed, can further influence its productivity. Data from the Mining Association suggests that optimizing the stroke can improve the crusher's capacity by up to 30%. Operators should also consider the type of material being processed; for example, harder materials may require a different adjustment than softer ones. Staying attentive to these adjustments, alongside routine maintenance checks, allows operators to achieve sustained performance while minimizing operating costs and reducing downtime.

Cone crushers are vital for efficiently crushing materials in various industries, but like all machinery, they can face common issues that hinder performance. Understanding these problems is the first step in troubleshooting. One frequent issue is uneven wear of the mantle and concave liners, which can affect the quality of the crushed material. Regular inspection and timely replacement of these parts are crucial for maintaining optimal productivity.

Another common problem is overloading, which can lead to increased pressure and potential damage to the internal components. Operators should be vigilant about the crusher’s load limits and ensure materials are fed appropriately to avoid excessive strain. Implementing routine maintenance checks can help identify issues before they escalate into costly repairs.

To enhance the longevity and performance of your cone crusher, here are some tips: First, always monitor the oil levels and ensure proper lubrication to prevent overheating. Secondly, keep the feeds clean and consistent to avoid blockages and overloading. Lastly, maintain a log of maintenance activities and machine performance metrics to identify patterns and areas for improvement over time. By following these guidelines, operators can minimize downtime and maximize the efficiency of their cone crushers.

| Component | Function | Common Issues | Troubleshooting Techniques | Maintenance Tips |

|---|---|---|---|---|

| Mantle | Crushes materials in the crushing chamber. | Wear and tear, misalignment. | Check for unusual vibrations, replace if thickness is below 1 inch. | Regularly inspect for wear, adjust alignment as needed. |

| Concave | Forms the outer part of the crushing chamber. | Cracking, excessive wear. | Look for visible cracks; if present, replace the concave. | Monitor wear patterns, replace when necessary. |

| Main Shaft | Supports the mantle and transmits crushing force. | Bending, wear on bearings. | Inspect for straightness, check bearings for play. | Lubricate regularly, ensure alignment. |

| Hydraulic System | Controls the movement of the mantle and adjustment of the cone. | Leaks, pressure loss. | Check fluid levels and connections, replace seals as necessary. | Regularly monitor fluid levels, maintain hoses and fittings. |

| Dust Seal | Prevents dust and debris from entering the bearing assembly. | Wear, cracks. | Inspect for breaches, replace if damaged. | Keep areas free of debris, inspect during regular maintenance. |