In the world of mining and aggregate processing, understanding the intricacies of equipment is essential for optimizing performance and minimizing downtime. Among the critical components of such machinery, Cone Crusher Parts play a pivotal role in ensuring the efficiency and longevity of crushing operations. This comprehensive guide delves into the various parts of cone crushers, providing valuable insights into their functions, maintenance, and the latest industry trends. By exploring real-world examples and practical solutions tailored for different operational needs, this blog aims to equip professionals with the knowledge necessary to enhance productivity and tackle common challenges in the field. Whether you are an industry veteran or a newcomer, this guide offers a wealth of information to better understand and utilize Cone Crusher Parts effectively.

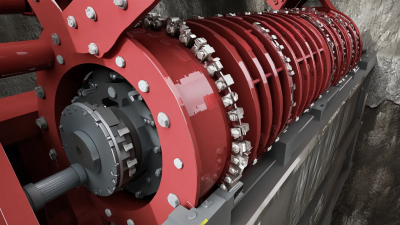

When exploring the critical roles of cone crusher components, it's vital to understand how each part contributes to overall efficiency and productivity in the crushing process. The main components include the mantle, concave liners, and the hydraulic system, each with specific functions that greatly impact performance. According to a recent industry report by the International Journal of Minerals, Metallurgy, and Materials, poorly maintained parts can lead to a decrease in operational efficiency by nearly 30%, emphasizing the importance of proper maintenance.

Tip: Regularly inspect and replace worn-out parts to enhance reliability and prevent unexpected downtimes. Maintaining optimal settings for the hydraulic system also ensures the cone crusher operates within its designed parameters, safeguarding against major failures and extending the lifespan of key components.

Moreover, the design and material quality of the concave liners and mantle significantly influence the wear rates and overall throughput. Studies indicate that advanced materials, such as high manganese steel, can improve wear resistance by up to 50% compared to standard materials. By investing in quality components and technology, operators can optimize performance, reduce operational costs, and enhance productivity over time.

Tip: Evaluate the latest technology trends in materials and design to stay ahead in efficiency and performance metrics in the competitive crushing industry.

When selecting materials for cone crusher parts, durability and performance are paramount. The harsh operating conditions and grinding forces in a crushing environment necessitate the use of high-quality materials that can withstand significant wear and impact. Commonly adopted materials include high manganese steel, alloy steel, and chromium carbide, each offering unique advantages. High manganese steel is favored for its exceptional capacity to absorb shock and resist wear, making it a go-to choice for liners and other critical components.

In addition to the alloy composition, the manufacturing process plays a crucial role in the performance of cone crusher parts. Advanced techniques such as heat treatment and surface hardening can significantly enhance the material properties, ensuring longer service life and reduced maintenance costs. Implementing these methods allows manufacturers to create parts that not only improve operational efficiency but also reduce the frequency of replacements, leading to decreased downtime and increased productivity in mining and aggregate processing operations.

| Part Name | Material Used | Durability Rating | Performance Factor | Industry Application |

|---|---|---|---|---|

| Mantle | Manganese Steel | High | Excellent | Mining |

| Concave | High Chrome Iron | Medium | Good | Construction |

| Spider Cap | Cast Steel | High | Very Good | Aggregates |

| Bowl Liner | Manganese Steel | High | Excellent | Mining |

| Drive Shaft | Alloy Steel | Medium | Good | Construction |

When examining the intricacies of cone crushers, real-world examples of failures can provide invaluable insights for operators and manufacturers alike. A common failure point involves bearing fatigue, which often stems from inadequate lubrication. According to a study by the International Journal of Engineering and Technology, nearly 38% of cone crusher failures are attributed to bearing issues. This emphasizes the importance of a robust lubrication system to ensure the longevity of crucial components.

Another notable case is the unanticipated wear on the manganese liners, which can result in significant downtime. The Mining and Metallurgy Engineering Society reported that excessive wear can reduce a crusher's efficiency by up to 25%. Regular monitoring and maintenance schedules are essential to identify wear patterns early and prevent catastrophic failures. Learning from these experiences can drive improvements in design and maintenance protocols, ultimately increasing operational efficiency and reducing costs for mining operations.

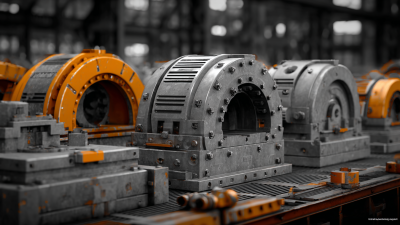

In recent years, the cone crusher industry has experienced significant technological advancements that have enhanced efficiency and performance. Leading manufacturers have introduced innovative features such as automated adjustments, real-time monitoring systems, and advanced design elements that improve material throughput and reduce operational costs. For instance, the integration of AI-driven predictive maintenance tools allows operators to foresee potential failures and optimize maintenance schedules, significantly increasing uptime.

Case studies from industry giants exemplify the impact of these innovations. One notable example is a recent project where a major manufacturer implemented a new cone crusher model equipped with an advanced hydraulic system. This improved the machine's crushing capability by 20%, while simultaneously lowering energy consumption by 15%. Another study highlights the introduction of a modular design that facilitates easier and faster maintenance. This design not only shortens downtime but also allows for greater flexibility in adapting to various crushing scenarios. Overall, such advancements reflect a trend toward smarter, more efficient cone crushers that meet the evolving demands of the mining and aggregate sectors.

Maintaining cone crusher parts is essential for ensuring longevity and efficiency in operations. Regular inspections and routine maintenance can prevent costly breakdowns and extend the lifespan of crucial components. One of the best practices is to schedule regular lubrication checks, ensuring that bearings and other moving parts receive adequate grease. A well-lubricated machine operates smoothly, reducing wear and tear over time.

Another tip for maintenance is monitoring the wear levels of components such as liners and mantles. Implementing a wear monitoring program not only helps in identifying when parts need replacement but also aids in optimizing performance. Keeping track of wear patterns can guide adjustments in operational parameters to improve the efficiency of the crusher. Regularly replacing worn parts ensures the machine continues to operate at peak performance, minimizing downtime and maximizing productivity.

Lastly, consider adopting a training program for operators to ensure that they understand optimal operating conditions and maintenance procedures. Educating the team on the importance of adhering to maintenance schedules and proper handling techniques can significantly impact the overall efficiency of the cone crusher. A knowledgeable crew is a key asset in prolonging the life of the equipment and achieving consistent output.