In today's competitive mining industry, selecting the right manufacturer for high-quality Mining Stone Crusher Parts is crucial for ensuring operational efficiency and reducing maintenance costs. According to a recent report by Grand View Research, the global stone crushing equipment market is expected to reach USD 8.5 billion by 2025, highlighting the growing demand for effective and reliable mining solutions. With an increasing focus on sustainability and efficiency, the choice of manufacturer not only impacts the durability and performance of the equipment but also influences compliance with industry standards and regulations.

Additionally, the integration of advanced manufacturing technologies, as noted in the Industrial Internet Consortium, is transforming the production of Crusher Parts, making it essential for companies to navigate the certification processes properly. This blog will provide insights into the key factors to consider when choosing a manufacturer, alongside essential industry certifications that guarantee quality and reliability.

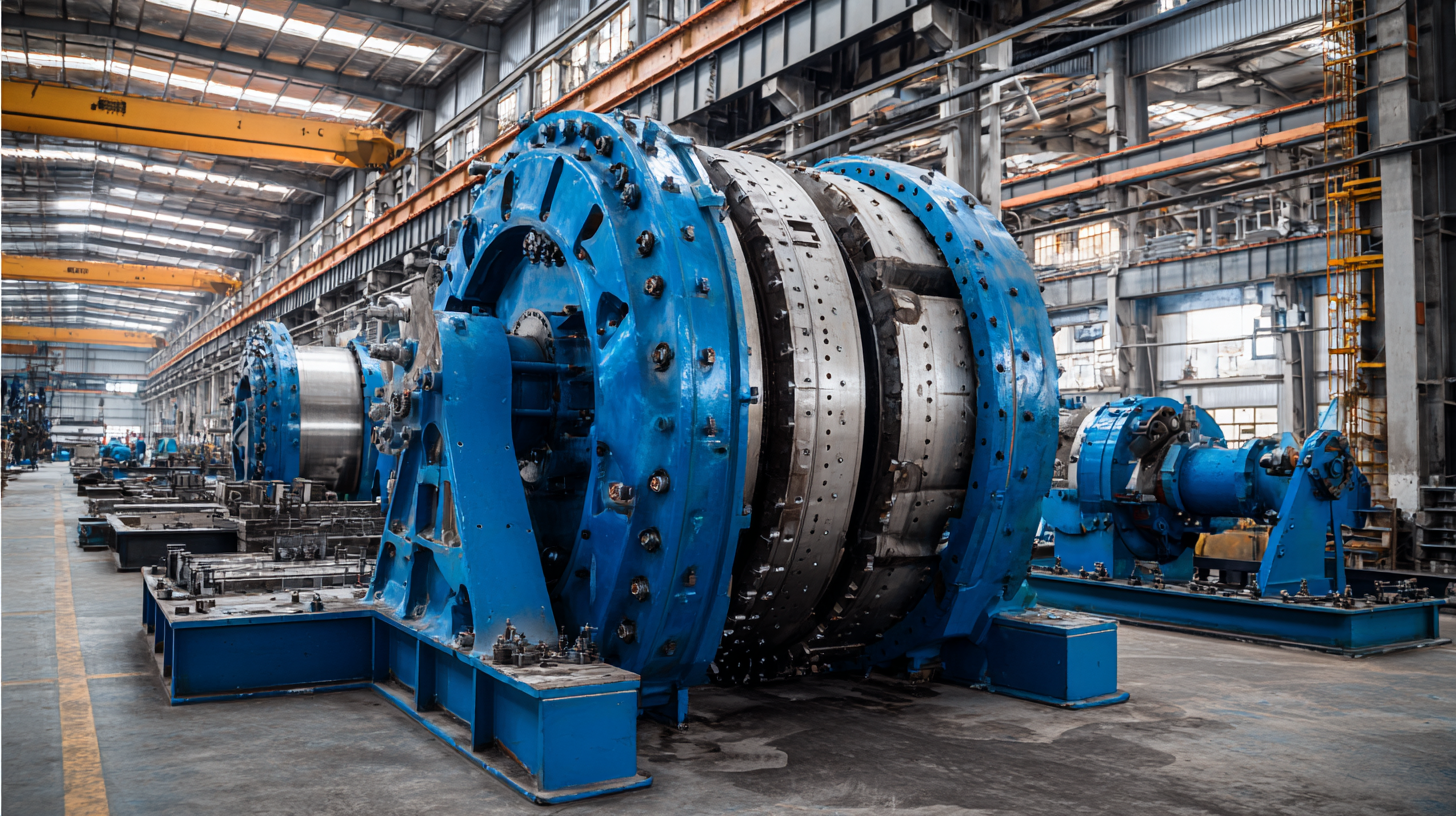

In the mining industry, the efficiency of operations heavily relies on the quality of equipment used, particularly in the case of stone crushers. According to a report by the International Journal of Mining Science and Technology, high-quality parts can enhance operational efficiency by up to 30%. This improvement often translates to higher production rates and reduced downtime, significantly impacting the bottom line for mining companies. When choosing a manufacturer for stone crusher parts, it is crucial to prioritize quality to ensure that machinery operates smoothly and effectively under the demanding conditions of mining environments.

Moreover, research from the Mining Equipment Manufacturers Association indicates that using genuine high-grade components minimizes the risk of equipment failure. In fact, machinery that is equipped with certified parts can operate more efficiently and extend lifespan by approximately 25%. This emphasizes the importance of selecting a reliable manufacturer who is committed to producing durable and precise equipment. Investing in quality parts ultimately leads to a more sustainable mining operation, preserving both resources and operational costs in the long run.

| Criteria | Importance Level | Impact on Efficiency | Quality of Parts Measurement |

|---|---|---|---|

| Material Quality | High | Direct positive impact on durability and performance | Inspected through material certifications and supplier audits |

| Manufacturing Process | High | Affects precision and reliability of components | Evaluated through process documentation and quality assurance practices |

| Supplier Reputation | Medium | Indicates reliability and previous performance | Measured through customer reviews and case studies |

| After-Sales Support | High | Ensures quick fixes during operational issues | Assessed by service level agreements and response time metrics |

| Cost-Effectiveness | Medium | Balances quality and financial performance | Evaluated through total cost of ownership analyses |

When selecting mining stone crusher parts, it’s crucial to consider specific specifications that can significantly impact performance and longevity. According to a recent industry report by Mordor Intelligence, about 35% of operational issues in mining operations can be traced back to subpar equipment components. Thus, focusing on quality should be your top priority.

First, look for high wear resistance materials, such as high manganese steel or alloy steel, which have proven to extend the lifespan of parts by 15-20% compared to standard materials. Additionally, precision engineering for a perfect fit can minimize wear and tear, leading to a 10% reduction in downtime, as highlighted in a study by Grand View Research.

Tips: Always request manufacturing certifications like ISO 9001 to ensure that the parts meet global quality standards. Furthermore, understand the part specifications according to the specific model of your crusher to enhance compatibility and performance. Engaging with manufacturers that offer extensive warranties can also protect your investment, ensuring peace of mind while optimizing productivity in your mining operations.

When selecting a manufacturer for mining stone crusher parts, durability stands as a fundamental criterion. High-quality mining equipment must withstand extreme operational conditions, including abrasive materials and heavy loads. Industry standards such as ISO 9001 certification and adherence to the ASTM (American Society for Testing and Materials) guidelines can help ensure that the parts you procure will perform reliably over time. A manufacturer that consistently meets these standards demonstrates a commitment to quality and longevity in its product offerings.

When selecting a manufacturer for mining stone crusher parts, durability stands as a fundamental criterion. High-quality mining equipment must withstand extreme operational conditions, including abrasive materials and heavy loads. Industry standards such as ISO 9001 certification and adherence to the ASTM (American Society for Testing and Materials) guidelines can help ensure that the parts you procure will perform reliably over time. A manufacturer that consistently meets these standards demonstrates a commitment to quality and longevity in its product offerings.

Additionally, utilizing advanced materials and innovative manufacturing techniques is crucial in boosting the durability of mining equipment. For instance, parts made from high-alloy steels or wear-resistant alloys can significantly reduce wear and tear, minimizing downtime and maintenance costs. It’s essential to inquire about a manufacturer’s research and development efforts, as continuous improvement in their product design can lead to superior performance in real-world mining applications. Ultimately, choosing a manufacturer who prioritizes these key industry standards will lead to more robust and resilient mining operations.

In the ever-evolving mining industry, understanding the major trends influencing the quality of mining crusher components is crucial for choosing the right manufacturer. One significant trend is the increasing focus on sustainable manufacturing practices. As environmental regulations tighten, manufacturers are adopting eco-friendly production methods, ensuring that their products not only perform well but also adhere to sustainability guidelines. This shift not only enhances the overall quality of the parts but also reflects a manufacturer's commitment to corporate responsibility.

Another critical trend is the advancement of technology in manufacturing processes. The integration of automation and sophisticated quality control systems enables manufacturers to produce more precise and durable mining crusher parts. This technological improvement results in consistent product quality and helps miners avoid costly downtime due to equipment failure.

When selecting a manufacturer, consider these tips: first, assess their commitment to sustainability and quality certifications; second, inquire about the technologies they use in their production processes. These steps can help ensure that you're investing in mining crusher components that will meet your operational needs and stand the test of time.

When it comes to mining operations, the quality of stone crusher parts can significantly impact both performance and maintenance costs. Evaluating the cost-effectiveness of high-quality mining stone crusher parts is crucial for maximizing efficiency and minimizing outages. While the initial investment may be higher, the long-term benefits often outweigh the costs. High-quality parts tend to have a longer lifespan, lower failure rates, and improved operational efficiency, leading to substantial savings over time.

Tips for choosing the right parts include thoroughly researching manufacturers and their reputations within the mining industry. Look for suppliers that offer warranties and have a proven track record of producing durable components. It's also helpful to compare materials and design features, as these factors can significantly influence performance and longevity.

Additionally, consider the total cost of ownership rather than just the upfront price. High-quality parts may come with a higher initial cost, but they can reduce the frequency of replacements and repairs. Calculating potential downtime and its associated costs can provide valuable insights into the true cost-effectiveness of the parts you choose. Investing in quality today can lead to reduced operational headaches and increased profitability in the long run.