Choosing the right jaw crusher part is crucial for maximizing the performance and efficiency of your crushing operations. In the world of mining and aggregate processing, the jaw crusher serves as a vital piece of equipment that directly impacts the overall productivity of the entire system. As such, understanding the specific components of a jaw crusher and how they contribute to its function is essential for operators and decision-makers alike.

The selection of jaw crusher parts should be guided by various factors, including the material being processed, operational conditions, and maintenance requirements. By assessing these elements, one can better determine which parts will deliver optimal performance and longevity. In this article, we will delve into the key considerations when choosing jaw crusher parts, ensuring that your investment translates into enhanced efficiency and lower operational costs. Whether you're looking to replace worn-out components or enhance the capacity of your existing machinery, making informed choices about jaw crusher parts can lead to significant improvements in your crushing operations.

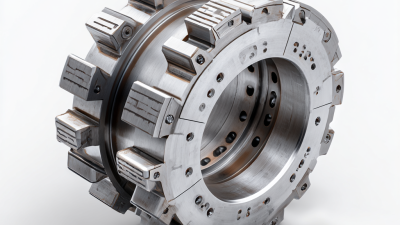

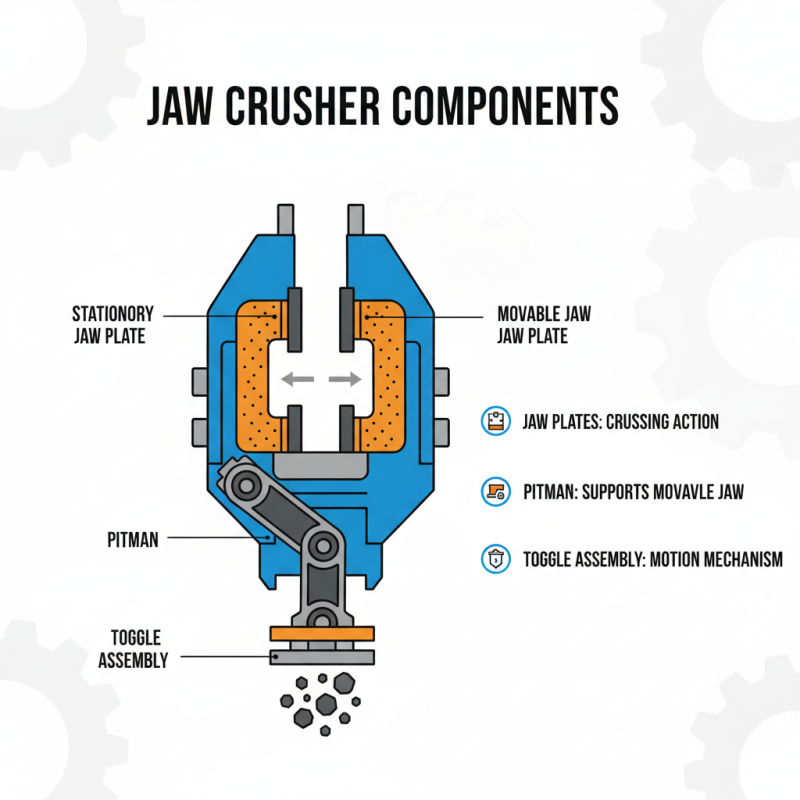

Understanding the various components of a jaw crusher is essential for achieving optimal performance. At the heart of the jaw crusher are its main parts: the jaw plates, the pitman, the toggle assembly, and the stationary and movable jaws. Each of these components plays a crucial role in the crushing process. The jaw plates are responsible for the actual crushing by oscillating against each other, and their material and design can significantly influence both the efficiency and lifespan of the equipment. The pitman, which supports the movable jaw, is designed to absorb the heavy loads from the crushing process, making its construction critical for durability.

In addition to these primary components, understanding the function of the toggle assembly is crucial. The toggle mechanism provides the necessary force and motion for the jaw to crush materials effectively. The configuration and quality of this component directly affect the crusher’s efficiency and maintenance needs. Moreover, the integration of wear parts, such as cheek plates and liners, must be considered as they protect the main structure from wear and tear, extending the operational life of the jaw crusher. Properly selecting and maintaining these parts not only enhances performance but also minimizes downtime and repair costs, making it vital for operations relying on crushing equipment.

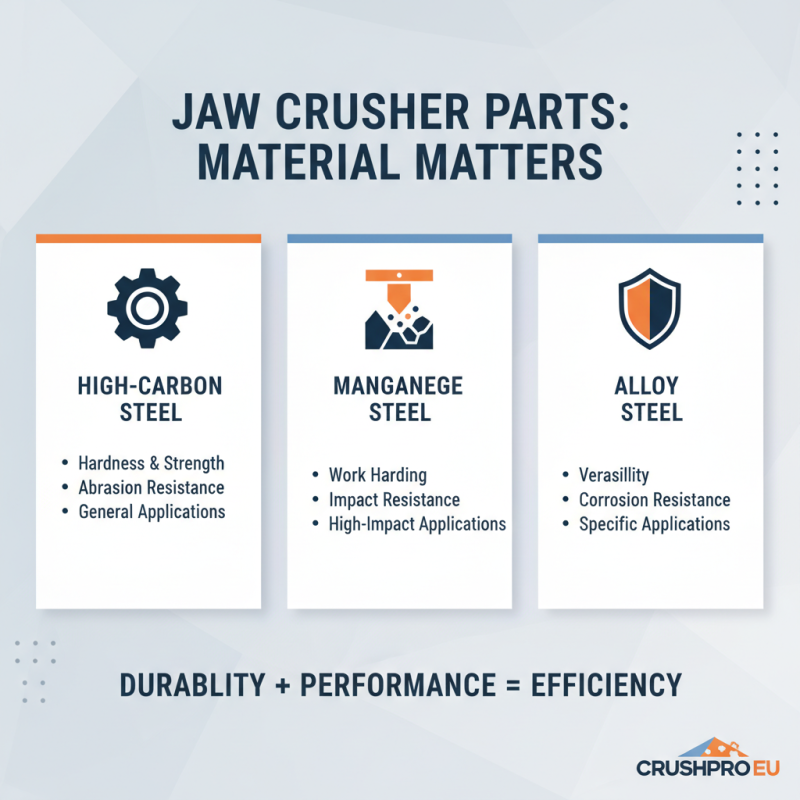

When selecting the right jaw crusher part, the material composition plays a crucial role in ensuring the durability and performance of the equipment. High-quality materials not only enhance the lifespan of individual components but also contribute to the overall efficiency of the crushing process. Common materials used in jaw crusher parts include high-carbon steel, manganese steel, and alloy steel, each offering distinct advantages based on the operational needs and environmental conditions. For instance, manganese steel is particularly favored for its excellent work hardening properties, making it ideal for high-impact applications.

In addition to the type of material, the specific composition can significantly impact the mechanical properties of the jaw crusher parts. Elements such as carbon, manganese, and chromium can be adjusted to alter hardness, toughness, and wear resistance. The right balance of these elements is essential for optimizing performance and reducing the frequency of replacements. Moreover, understanding the working conditions—such as the type of material being crushed and the size of the output—can guide the choice of material composition, ensuring that the jaw crusher operates at peak efficiency while minimizing downtime caused by component wear. By carefully considering these factors, operators can enhance the operational effectiveness of their jaw crushers and ensure long-term reliability.

When selecting the right size and configuration for your jaw crusher, several factors come into play that can significantly enhance performance. The size of the jaw crusher should be closely matched to the dimensions of the material being processed. Considerations such as the feed size and the desired output size are crucial in determining the optimal jaw plate width and length. A correct match not only ensures efficient material flow but also maximizes crushing capacity and minimizes wear.

Tips: Always measure the maximum feed size and assess the hardness of the material to choose the appropriate jaw crusher. It's essential to take into account the required throughput, which can influence the size of the motor and other components that support the jaw crusher's operation.

Configuration is equally vital. Jaw crushers come in various designs, including single-toggle and double-toggle models, each offering unique advantages. The choice between these configurations can depend on factors such as the required reduction ratio and working environment. A single-toggle design typically allows for a more extensive range of motion, while double-toggle might deliver a higher crushing force.

Tips: Evaluate the application specifics and consult with industry professionals to understand which configuration will give you the best performance based on your operational needs. Properly configuring your jaw crusher can lead to improved efficiency, reduced maintenance costs, and enhanced durability over time.

Wear rates significantly impact the efficiency and longevity of jaw crushers, making it crucial to select the right parts for optimal performance. According to a report by the Mining Industry Association, the average wear rate for jaw crusher parts can range from 2 to 8 tons of crushed material per wear piece, depending on the material being processed and operational conditions. When wear rates are elevated, the energy consumption increases, leading to reduced operational efficiency. A study published in the Journal of Materials Processing Technology reveals that a 10% increase in wear rates can lead to a 5% decrease in processing efficiency, underscoring the importance of timely replacement and proper maintenance.

Furthermore, the longevity of jaw crusher components is closely tied to wear material quality and design. A recent analysis by the Institute of Mining Engineers indicates that using high-quality alloys and innovative wear-resistant materials can extend the life of wear parts by as much as 30%. This not only enhances the operational uptime of the equipment but also reduces the associated maintenance costs over time. Therefore, understanding the wear rate dynamics and investing in suitable high-performance parts is essential for maximizing productivity and minimizing disruptions in the crushing process.

When selecting the right jaw crusher part for optimal performance, evaluating manufacturer specifications and standards for quality assurance is crucial. Many operators overlook the importance of detailed specifications, which can lead to inefficiencies and increased operational costs. According to a report by the International Journal of Mining Science and Technology, using subpar components can decrease crusher efficiency by up to 20%, underscoring the necessity of choosing high-quality parts that meet rigorous industry standards.

One critical aspect to consider is the material composition of the jaw crusher parts. High manganese steel is commonly used for its excellent wear resistance and ability to withstand heavy impact loads. A study by the American Society of Mechanical Engineers indicates that components made from high-grade alloys can extend service life by approximately 30% compared to standard cast iron parts. Additionally, manufacturers that comply with ISO 9001 standards are more likely to adhere to consistent quality management practices, ensuring that the parts not only meet specifications but also enhance overall performance.

Moreover, it is essential to assess testing protocols and certifications. Parts that have undergone comprehensive testing can provide insights into their reliability and durability. The National Institute for Occupational Safety and Health (NIOSH) emphasizes that components with documented performance metrics reduce the risk of equipment failure and enhance operational safety. By prioritizing manufacturers with robust quality assurance measures, operators can significantly improve the lifespan and efficiency of their jaw crushers, ultimately leading to better productivity in their mining or aggregate operations.