Choosing the right Cone Crusher Concave is crucial for effective crushing operations. This component plays a vital role in the overall performance of the cone crusher. Selecting the right material and design can greatly impact productivity and product quality.

Many factors influence your choice. The type of material being crushed matters. Harder materials may require a different concave design than softer ones. Additionally, the size of the concave should match the crusher's specifications.

However, finding the perfect Cone Crusher Concave isn’t always straightforward. It often entails a bit of trial and error. Misjudgments can lead to inefficiency. This can be frustrating, but it's part of the learning process. Taking time to evaluate your options is essential. Make sure to review performance data and consult with experts when necessary.

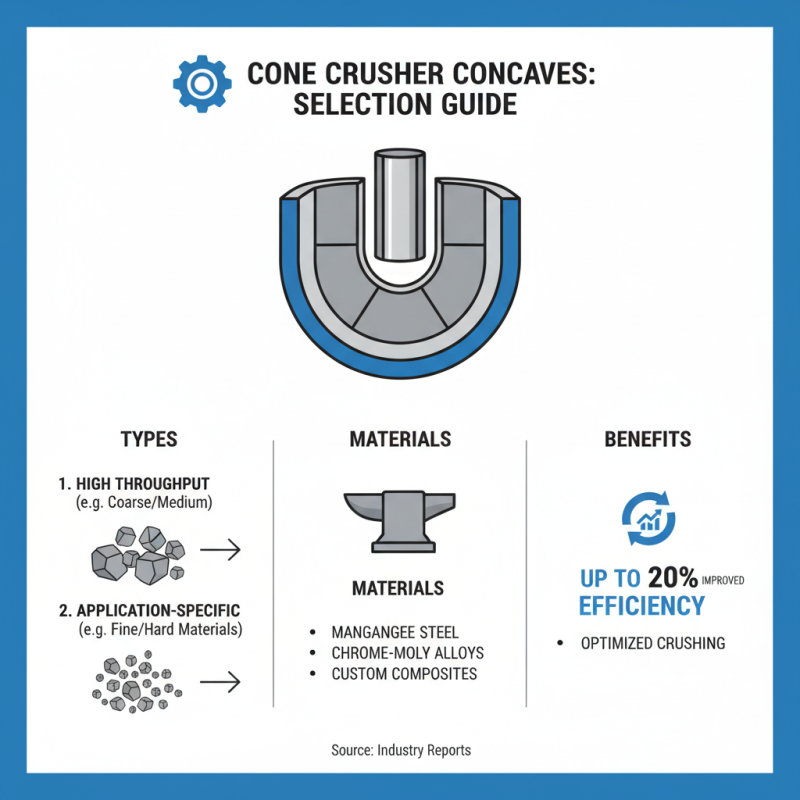

When choosing a cone crusher concave, it's crucial to understand the different types available. Cone crusher concaves vary in design, material, and application. Some are optimized for high throughput, while others are tailored for specific materials. According to industry reports, the right concave can improve crushing efficiency by up to 20%.

There are three main types of concaves: standard, medium, and fine. Standard concaves are versatile and cater to various applications. Medium concaves balance throughput and product size. Fine concaves produce finer material but may require more energy. Always consider the hardness and abrasiveness of your material.

Tips: Before rushing into a decision, evaluate your operational needs. Ask for input from your team. Also, double-check the compatibility of concave with your crusher model. Misalignment can lead to premature wear and increased costs. Regularly review your performance metrics to determine if you're maximizing productivity.

When selecting a cone crusher concave, material composition plays a vital role. The type of steel used can significantly impact the concave's lifespan and performance. High manganese steel is commonly preferred due to its excellent work-hardening properties. It becomes tougher under high stresses, making it suitable for abrasive materials. However, it may not always stand up to certain rock types.

Choosing the correct alloy can be tricky. Some concaves use lower-grade materials to reduce costs. These might fail under heavy load. Users may see early wear or even breakage. A balance is needed between cost and durability. Examine the specifications carefully. Additional elements can enhance wear resistance, but may also increase price. Remember, not all concaves are created equal.

Keep in mind that every application is unique. Factors like material type, moisture content, and size distribution can affect performance. Testing in real conditions can provide insights that specs do not reveal. Be prepared to reassess your choice if issues arise. Sometimes, a trial and error approach is necessary to find the perfect fit.

Choosing the right cone crusher concave is crucial for optimal performance. Understanding wear patterns helps in this selection process. Wear patterns indicate how the material interacts with the concave. They reflect the crushing dynamics at play. Over time, these patterns evolve, which can impact productivity and efficiency.

When analyzing wear, consider the materials processed. Different materials create distinct wear characteristics. For instance, harder rocks might lead to faster wear rates. Regularly inspecting concaves for wear progression is essential. It can reveal whether a change is needed or if adjustments can enhance performance.

Some wear patterns might display uneven erosion, signaling potential issues. This could mean incorrect fitment or operating at suboptimal settings. Pay attention to these details. They may seem minor, yet they can significantly influence overall results. A precise understanding of wear patterns ultimately leads to better decision-making.

This bar chart presents the wear intensity of cone crusher concaves at different stages of usage. Understanding these wear patterns can help in selecting the right concave type for optimal performance and longevity.

Choosing the right cone crusher concave is crucial for optimal performance. The size and shape of the concave directly affect the crushing process. A well-fitted concave enhances efficiency. However, you should consider the specific requirements of your operation.

When selecting, think about the material you’re crushing. Harder materials may require a deeper profile. In contrast, softer materials might work better with a shallower design. There’s a balance between durability and performance; too deep could lead to excessive wear.

Tips: Always monitor the wear pattern. This can guide your future choices. Experiment with different profiles to see what works best. Don’t overlook the importance of plant configuration. Layout can affect the capacity and efficiency of your equipment. Understanding these factors can save you time and money.

Choosing the right cone crusher concave involves careful consideration of cost versus longevity. A cheaper concave may save money upfront but could wear out quickly. This leads to more frequent replacements, increasing long-term costs. Investing in durable options can be wise. It prolongs operational efficiency and reduces downtime.

Tips: Always assess your production needs. Analyze the material you process. The right concave should match your specific requirements. Look for quality certifications. This can help ensure you're getting the best value for your investment.

Keep in mind that not all concaves perform equally. Some might fracture under high pressure. Others may corrode faster when exposed to harsh materials. Regular maintenance checks are vital. They reveal wear patterns and help determine when to reorder. Consider the trade-offs between price and quality. A poor choice today could cost more tomorrow.

| Material Type | Cost (per unit) | Lifespan (hours) | Wear Resistance | Recommended Use |

|---|---|---|---|---|

| High Manganese Steel | $150 | 800-1200 | High | Medium to hard rock |

| Martensitic Steel | $180 | 700-1000 | Very High | Recycling and demolition |

| Alloy Steel | $120 | 600-900 | Medium | Soft rock applications |

| Ceramic Matrix Composite | $220 | 1000-1500 | Excellent | High performance, extreme conditions |