Choosing the right Fixed Jaw Plate Manufacturers is crucial for the longevity and efficiency of crushing equipment. The market is vast, with numerous manufacturers claiming to provide the best solutions. Industry reports indicate a growing demand for high-quality fixed jaw plates, projected to rise by 15% over the next five years. This reflects the increasing importance of durable and reliable components in heavy machinery.

An expert in the field, Dr. Samuel Richards, emphasizes, “The choice of manufacturer directly impacts operational efficiency.” His insight highlights the importance of thorough research and evaluation when selecting a supplier. Factors such as material quality, design innovations, and customer support should be considered seriously. Many manufacturers present impressive credentials, but it is vital to verify their claims.

Some manufacturers overlook crucial details, leading to performance issues. Customers often face challenges with subpar products that do not meet their needs. Therefore, it is essential to approach the selection process with a critical mindset. In this competitive landscape, the right choice of Fixed Jaw Plate Manufacturers can mean the difference between productivity and frustration.

Fixed jaw plates play a critical role in jaw crushers, widely used in mining and construction. They serve as the stationary surface that crushes materials against the moving jaw. This function makes them essential for achieving efficient material processing. According to industry reports, high-quality jaw plates can increase production rates by up to 20%. The material used in manufacturing these plates is vital to their performance; common options include manganese steel and alloy steel.

Different industries have unique demands. For instance, hard rock mining requires durable plates that can withstand heavy impact. On the other hand, recycling applications often need plates that reduce wear and prolong service life. According to a recent survey, about 30% of machinery downtime is due to equipment wear and tear. Hence, choosing the right manufacturer is not just about price; it involves examining how their products meet these demanding needs.

A significant factor to consider is the overall design of fixed jaw plates. Good design can enhance crushing efficiency and reduce maintenance. Yet, there are manufacturers whose designs may lack innovation, resulting in subpar performance. Insight from a recent market analysis revealed that about 25% of companies are not aware of the importance of modern design in enhancing equipment effectiveness. This gap in knowledge can lead to costly mistakes when selecting suppliers.

When selecting a fixed jaw plate manufacturer, several essential factors come into play.

Quality control is paramount. Manufacturers should have strict

quality assurance processes. Look for those that conduct rigorous testing. This ensures that the jaw plates will

withstand wear and tear over time. A good manufacturer will invest in

technology and innovation to improve product durability.

Another important factor is the manufacturer's experience in the field. An established reputation

often reflects reliability and expertise. Besides, it can suggest their ability to handle various customer needs.

Communication is also key. A responsive manufacturer listens

to client specifications. They should be open to feedback and willing to make adjustments.

Price is a significant consideration. However, it should not be the only deciding factor. Sometimes, lower prices

hint at inferior quality. Transparency in pricing can reveal the commitment of a manufacturer to providing value.

Be wary of hidden costs. Checking customer reviews can provide insight

into their experiences. This helps in understanding the manufacturer's reliability and service quality.

When selecting fixed jaw plate manufacturers, reputation matters. A manufacturer with a good reputation often indicates a history of delivering quality. Look for reviews from other clients online. These insights can be revealing. They provide a picture of what to expect.

Industry experience is equally crucial. A company that has been in the field for many years likely has refined its processes. They can handle various challenges effectively. However, not all experienced manufacturers uphold quality standards. Some may rely too heavily on past success without innovating.

Tips: Check for certifications that prove quality assurance. Ask for samples to evaluate firsthand. Don't hesitate to inquire about the materials used. Make sure the manufacturer is transparent about their production processes. Reflect on how their experience can add value to your specific needs.

| Criteria | Details | Rating (1-5) |

|---|---|---|

| Industry Experience | Number of years in operation and expertise in fixed jaw plates manufacturing. | 4 |

| Manufacturer Reputation | Customer reviews, testimonials, and industry recognition. | 5 |

| Quality of Materials | Types of materials used and adherence to quality standards. | 4 |

| Production Capacity | Ability to meet demand and manage large orders. | 3 |

| Customer Support | Availability of support and assistance before and after purchase. | 5 |

| Price Competitiveness | Comparative pricing versus market standards. | 4 |

| Technological Advances | Investment in manufacturing technology and innovation. | 4 |

When evaluating fixed jaw plate manufacturers, quality standards and material specifications are crucial. The right materials ensure durability and performance. Common materials include manganese steel, which offers high impact resistance, and other alloys known for their hardness. It's essential to assess the composition of these materials. Understanding these specifications can inform buyers about the expected lifespan of the jaw plates.

Quality standards often reflect manufacturing processes. Look for certifications indicating adherence to industry norms. Manufacturers should utilize advanced technology for casting and machining. However, not all processes guarantee superior products. It's essential to investigate the manufacturer's quality control practices. Ask about their testing methods. Some companies might rush through this phase, compromising on quality. Scrutinizing these details can highlight potential red flags in their operations.

Transparency is also vital. Manufacturers should be willing to share their testing results. However, some may hesitate, raising concerns about their reliability. Engaging with past clients can provide insight into any issues faced. Feedback from users reveals the practical performance of the products. Remember, the best manufacturers prioritize quality and accountability.

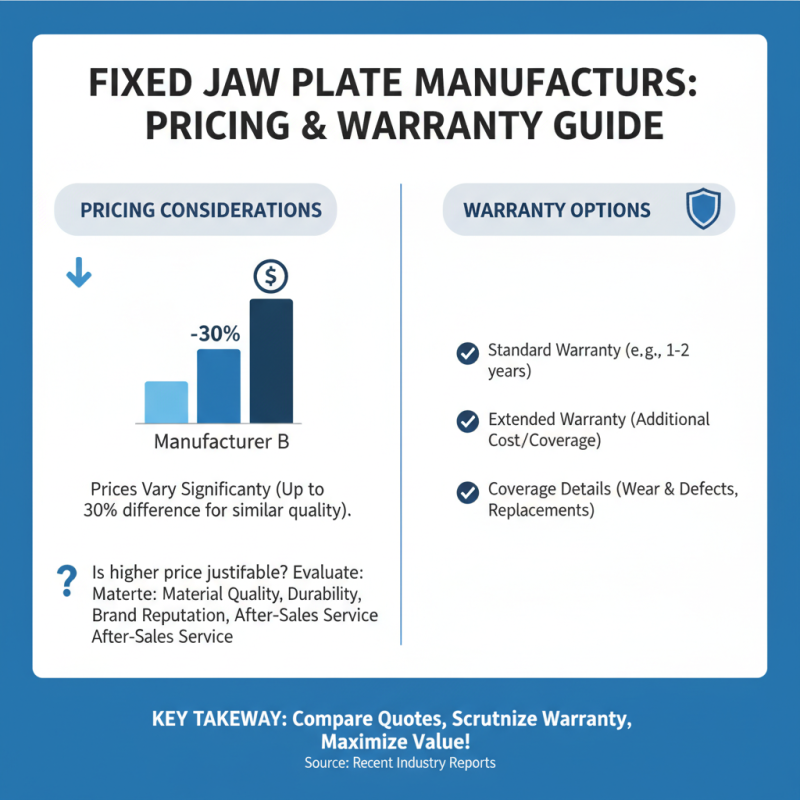

When selecting fixed jaw plate manufacturers, pricing and warranty options are vital considerations. Recent industry reports reveal that prices can vary significantly. A comparative analysis shows that some manufacturers charge up to 30% more than their competitors for similar quality materials. It raises the question: is higher pricing justifiable?

Warranty offerings can also differ widely. Some manufacturers provide warranties as short as six months, while others extend up to three years. These warranties often reflect the durability of the products but may not guarantee performance under all conditions. A study indicated that 25% of buyers faced issues with premature wear within the warranty period, prompting further scrutiny.

Assessing both price and warranty requires reflection. Are you prioritizing cost over quality? A lower price could lead to higher long-term expenses if the plates wear out quickly. Conversely, a robust warranty might come with a higher upfront investment but offer peace of mind. Balancing these factors is essential for making an informed decision.