Choosing the right Cone Crusher Mantle can significantly impact the efficiency of your operation. Industry reports indicate that improper mantle selection can lead to decreased production and increased operational costs. According to expert John Smith, "The right mantle can optimize your crushing process and fuel productivity."

In the world of mining and aggregates, the Cone Crusher Mantle plays a critical role. A well-matched mantle enhances the machine's performance and minimizes wear and tear. However, many operators underestimate its importance. They often overlook the specific requirements of their operational needs.

Research shows that a poor choice of mantle can reduce the crusher's output by nearly 30%. This statistic highlights the need for careful consideration. While choosing a mantle, operators should evaluate material types, expected throughput, and desired size reduction. Addressing these factors thoughtfully can lead to substantial improvements. The importance of a tailored approach cannot be overstated. Every operation has unique challenges and selecting the wrong mantle may hinder performance.

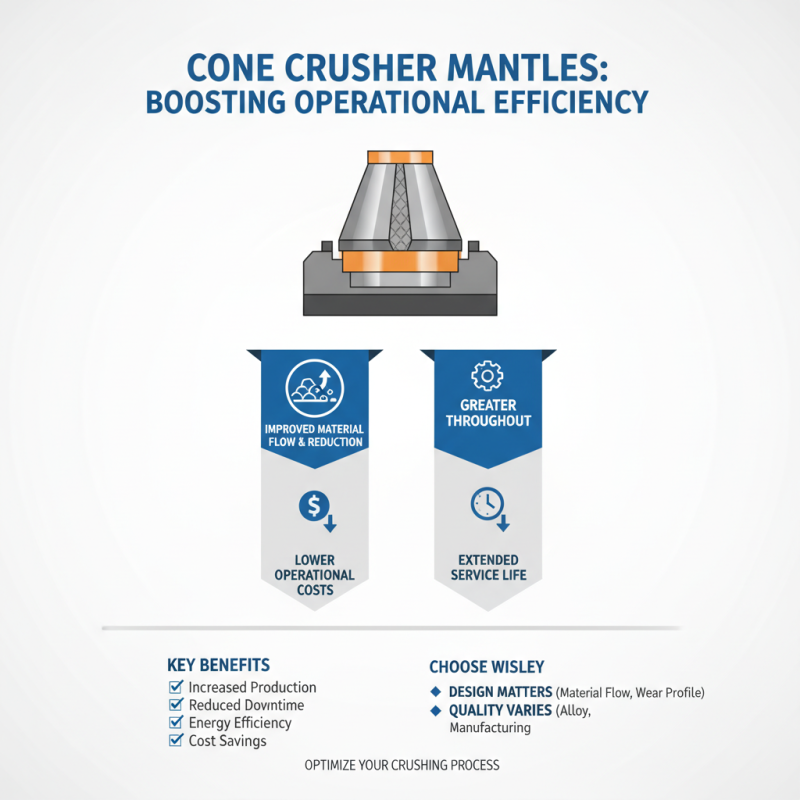

Cone crusher mantles play a crucial role in enhancing operational efficiency. These cast metal components are integral to the crushing process. Their design impacts material flow and reduction rates. A well-chosen mantle can result in better throughput and lower operational costs. However, not all mantles are created equal.

Tips: Understand your material. Different rocks require different mantle profiles. Select a mantle that matches the specifics of the material you are processing. This can lead to significant performance improvements.

Another key consideration is the wear pattern. As the mantle wears, it can change the dynamics of crushing. Monitoring wear levels regularly is essential. This can help prevent unexpected breakdowns and costly repairs. It is helpful to trial different mantles under similar conditions. This experimentation can reveal the best fit for your operation.

Remember to assess your operational goals. Are you aiming for higher volume or finer material? The right mantle can be disappointing if it does not align with your needs. Reflecting on past experiences can guide better choices. The ideal mantle selection is often a balance of performance, cost, and material compatibility.

Selecting the right cone crusher mantle is crucial for optimal operation. Several key factors come into play. Material type is one essential consideration. Different materials have varying hardness levels, which affect performance. The mantle must match the type of rocks processed. If it doesn't, inefficiencies arise.

Another important factor is the design of the mantle. The profile impacts how well the crusher works. A poorly designed mantle can lead to excessive wear or even crusher failure. Be mindful of the shape and size. This is often overlooked but can severely affect output.

Consider your operational conditions as well. Factors like moisture content and material gradation can influence mantle choice. An improperly selected mantle can lead to costly repairs. Always analyze wear patterns on existing mantles. This data can guide future selections and adjustments.

Selecting the appropriate cone crusher mantle is essential for achieving optimal performance in crushing operations. Various types of mantles are available, each serving unique functions. For instance, a standard mantle is perfect for general-purpose applications. It offers a balance of wear resistance and crushing efficiency.

In contrast, a long-throw mantle is designed for a more aggressive crushing action. This type is ideal for softer materials. However, it can lead to higher wear rates, necessitating frequent replacements. On the other hand, a short-throw mantle offers better performance with harder materials but may not manage softer ones effectively. It's critical to assess the materials you are working with.

It’s worth noting that even with the right mantle, factors like feed size and the intended product shape matter. Regular inspections might reveal unexpected wear patterns, prompting further evaluation of your choice. Every operation is different. Finding a mantle that aligns with your specific needs often requires trial and error.

Choosing the right material for a cone crusher mantle can significantly impact durability and performance. The mantle is critical in crushing operations, and selecting the correct material is vital. Common options include manganese steel and high alloy steel. Each offers distinct advantages based on specific applications.

Manganese steel is well-known for its high impact strength and resistance to abrasion. It works well in situations with high-impact forces. However, its performance can degrade in extremely harsh conditions.

High alloy steel, on the other hand, provides better wear resistance. Yet, it might lack the toughness of manganese. There’s a trade-off here that should not be overlooked.

Carefully evaluating your operational needs is crucial. Are you maximizing performance, or are you losing efficiency? Some users may overlook the importance of using the right material altogether. This can lead to premature failures and costly downtime. Reaction to wear patterns and material degradation must be part of your strategy. Keep refining your choice of mantle material for the best outcomes.

Regular maintenance is crucial for maximizing the lifespan of your cone crusher mantle. Considering that mantles can wear out quickly, following a rigorous inspection schedule is vital. Research indicates that properly maintained mantles can last up to 30% longer. To achieve this, schedule monthly checks and replace worn parts promptly.

Cleaning the mantle is equally important. Accumulated debris can lead to premature wear. Dust and dirt can act like an abrasive, increasing wear rates. Utilizing proper cleaning methods can reduce this risk. Use high-pressure water jets to remove stubborn materials. Also, consider the environment where the crusher operates. Dusty locations may require more frequent cleanings.

Monitoring operational parameters can prevent unnecessary damage. Tracking temperature, pressure, and load helps to assess the mantle's condition. Excessive heat indicates poor lubrication and can shorten lifespan. Many operations fail to consider these factors, leading to costly replacements. By staying vigilant, you can avoid such pitfalls and enhance productivity.

| Dimension | Material Type | Weight (lbs) | Lifespan (Hours) | Applications |

|---|---|---|---|---|

| 20 in | Manganese Steel | 250 | 1000 | Granite, Basalt |

| 24 in | High Chrome Iron | 320 | 900 | Limestone, Quartzite |

| 28 in | Alloy Steel | 400 | 1200 | Recycled Aggregates |

| 30 in | CrMo (Chrome Molybdenum) | 500 | 1500 | Iron Ore, Copper |

| 32 in | Bimetallic | 600 | 1800 | Sandstone, Shale |