When it comes to the selection of a cone crusher mantle, making an informed decision is crucial to optimizing performance and ensuring longevity in harsh operational environments. As industry expert John Smith, a leading figure in materials processing, aptly stated, "Choosing the right cone crusher mantle not only enhances efficiency but also significantly reduces operational costs." This insight emphasizes the importance of aligning the mantle's design and material composition with the specific demands of your crushing operations.

The right cone crusher mantle serves as a pivotal component that determines the wear characteristics, throughput, and overall functionality of the crusher. A well-matched mantle can lead to improved product shape, reduced downtime, and an overall increase in productivity. As manufacturers continue to innovate, understanding the various options available for cone crusher mantles ensures that businesses can meet their unique requirements while maintaining a competitive edge in the market.

In this guide, we will explore key considerations for selecting the appropriate cone crusher mantle, including material choices, design features, and performance metrics. By leveraging expert knowledge and industry standards, operators can master the selection process, ensuring that their equipment is tailored for optimal results in any application.

The cone crusher mantle is a critical component in the crushing process, playing a vital role in determining the efficiency and effectiveness of material size reduction. Positioned atop the cone crusher's main shaft, the mantle is responsible for crushing the material against the concave bowl liner. This triangular relationship between the mantle, the processed material, and the concave liner ensures that particles are crushed and reduced to the desired size. The shape and design of the mantle can greatly influence the material flow, the size of the product, and the overall operational performance of the crusher.

Understanding the operational mechanics of the mantle is essential for identifying the right type for your specific application. Factors such as material hardness, feed size, and desired output shape all play a role in selecting the appropriate mantle design. For instance, a taller mantle may be better suited for finer crushing requirements, while a shorter mantle can provide increased throughput for larger material sizes. By carefully evaluating these factors, operators can improve throughput, reduce wear costs, and ensure optimal operational performance of their cone crushers, ultimately leading to greater productivity and efficiency in the crushing process.

When selecting a cone crusher mantle, several important factors should be considered to ensure optimal performance and compatibility with your specific crushing requirements. First, it's essential to analyze the material composition of the mantle. Different materials provide varying levels of durability and wear resistance. For instance, manganese steel is commonly used for its excellent toughness, while high-chrome iron may be chosen for its hardness in applications involving abrasive materials.

Another crucial consideration is the design and geometry of the mantle. The profile of the mantle affects the flow of material through the crushing chamber, influencing both capacity and product size. Manufacturers offer various designs to suit different applications, so it's important to assess how a specific mantle shape will interact with the feed material and other components of your crushing system. Additionally, compatibility with your existing equipment, maintenance requirements, and the manufacturer's support can further influence your choice, ensuring that the selected mantle not only meets your operational needs but also contributes to your overall efficiency and productivity.

| Factor | Description | Impact on Performance |

|---|---|---|

| Material Type | Choosing the right material for the mantle affects durability and wear resistance. | Higher wear resistance leads to lower replacement frequency. |

| Cone Crusher Model | Different models have specific mantle designs; compatibility is crucial. | Proper fit ensures optimal crushing efficiency. |

| Crushing Application | Understanding the material size and type being processed influences selection. | Tailored designs improve throughput and product shape. |

| Profile Design | Different profiles can enhance production and protect the crusher. | Affects reduction ratios and flow of material. |

| Cost | Budget constraints may limit options, but cheaper isn’t always better. | Investment in quality can lead to savings on replacements. |

When selecting the right cone crusher mantle, it's crucial to understand the different types available and their specific applications. There are primarily two types of cone crusher mantles: standard and short head. Standard mantles are designed for large-scale operations where a larger feed size is expected, providing a coarser output. In contrast, short head mantles are optimized for finer product requirements, making them ideal for secondary crushing processes where reduced particle size is necessary.

Tips for choosing the right mantle include considering the material composition—high manganese steel is commonly used for its durability. Additionally, check the operational conditions and the type of material being crushed. Different materials will demand different mantle profiles for optimal performance. Lastly, ensure compatibility with your existing crusher model to avoid operational inefficiencies.

Another aspect to consider is the wear pattern of the mantle, which can significantly influence the productivity and efficiency of your crushing operation. Regularly monitoring the wear and tear will help in determining the right time for replacement and can keep your operations smooth. By assessing these factors, you can make an informed decision that aligns with your crushing needs.

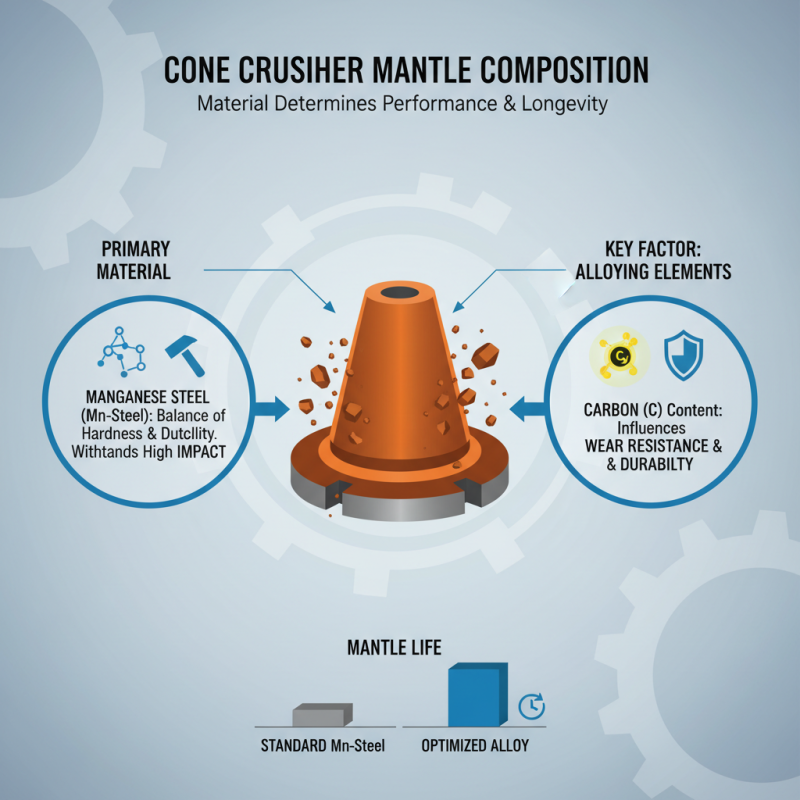

The material composition of a cone crusher mantle plays a crucial role in determining its performance and longevity. Typically, mantles are made from manganese steel, which offers a good balance of hardness and ductility. This composition allows the mantle to withstand the high impact forces exerted during crushing operations. However, variations in alloying elements, such as carbon, can significantly influence the wear resistance and overall durability of the mantle.

In addition to manganese, some manufacturers incorporate other materials like chrome or nickel to enhance specific characteristics of the mantle. For instance, chrome increases the hardness, thereby improving wear resistance, while nickel can enhance toughness. This variability means that selecting the right mantle composition is essential based on the specific crushing application and material being processed. For instance, processing abrasive materials may require a harder mantle, whereas more ductile options may be better suited for softer materials, ensuring optimal performance and reduced maintenance costs. Understanding these material properties is key to maximizing the efficiency and lifespan of your cone crusher.

Maintaining the integrity of your cone crusher mantle is crucial for extending its lifespan and ensuring optimal performance. Regular inspection is key; operators should routinely check for signs of wear or damage. Look for cracks, excessive wear patterns, and any signs of deformation. By identifying these issues early, you can address them before they lead to more significant problems that could require costly repairs or replacement.

Another essential maintenance tip is to ensure that the cone crusher operates within the recommended parameters. This includes monitoring the feed size and material type, as using unsuitable materials can accelerate wear. Furthermore, proper lubrication is vital; always use the manufacturer-recommended lubricant to reduce friction and wear on the mantle. Consistent maintenance schedules and adherence to operational guidelines will not only prolong the life of your cone crusher mantle but also enhance the overall efficiency of your crushing operations.