In the world of mining and aggregate processing, the jaw crusher stands out as a vital asset for efficient operations. As a cornerstone of material reduction, the efficiency and longevity of jaw crushers heavily rely on the quality and performance of their components. Therefore, finding the best jaw crusher parts in 2023 is crucial for enhancing both performance and durability. With advancements in technology and materials, new parts are being introduced to the market that can significantly optimize crushing processes and reduce operational downtime.

Selecting the right jaw crusher parts involves more than just finding replacements; it requires careful consideration of design, material composition, and compatibility with existing systems. The advancements in manufacturing techniques have enabled the production of components that not only withstand heavy usage but also offer improved wear resistance and operational efficiency. This emphasis on quality is essential for businesses aiming to maximize productivity and reduce maintenance costs.

As we explore the landscape of jaw crusher parts available this year, it becomes clear that investing in superior components is a strategic decision that pays dividends in the long run. The right choice in parts can lead to enhanced functionality and operational efficiencies, ensuring that jaw crushers remain at the forefront of mining and construction activities.

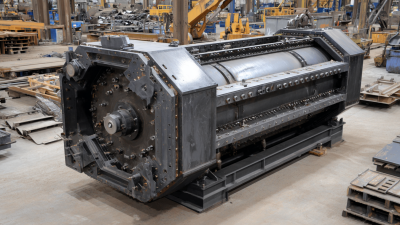

The performance and durability of a jaw crusher largely depend on its various components, which play critical roles in ensuring that the machine operates efficiently. Key elements such as the jaw plates, flywheel, and eccentric shaft are foundational to a crusher’s operational capabilities. According to the Mining Equipment and Services Industry Report, well-maintained jaw plates, typically made from manganese steel, can significantly enhance crushing efficiency and longevity by providing greater wear resistance. This ensures that the machine can withstand the high-stress conditions under which it operates, prolonging its service life.

Additionally, the flywheel’s mass and design play a crucial role in energy efficiency. A heavy-duty flywheel ensures that energy is stored and released during the crushing cycle, maintaining smooth operation. The eccentric shaft must also be meticulously crafted, as it is essential for converting rotational motion into the linear motion necessary for crushing materials. Studies indicate that the correct alignment and support of the eccentric shaft can reduce operational wear by over 20%, showcasing the importance of understanding each component's function in optimizing performance. Investing in high-quality parts and understanding these components will not only enhance the durability of jaw crushers but will also contribute to overall operational efficiency and reduced downtime.

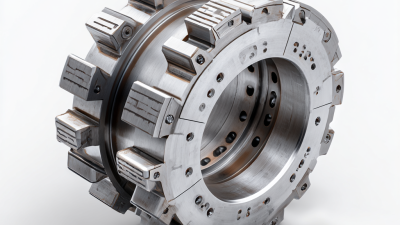

The durability and performance of a jaw crusher largely depend on the materials used in its components. High-quality materials such as manganese steel, carbon steel, and alloy steel are commonly employed in the manufacturing of jaw plates and other critical wear parts. Manganese steel, known for its exceptional abrasion resistance and toughness, is particularly effective in maintaining the integrity of the crushing surfaces, allowing the machine to withstand the harshest operating conditions. The specific alloy composition can also be tailored to improve performance attributes, such as impact resistance and hardness.

In addition to steel formulations, various protective coatings and heat-treatment processes can be applied to enhance the longevity of jaw crusher parts. Wear-resistant coatings can significantly reduce the impact of wear and tear, while heat treatment techniques can increase the hardness and improve resistance to deformation under stress. These innovations ensure that components do not only perform optimally but also have prolonged service life, leading to reduced downtime and maintenance costs. The careful selection of materials and processing methods is essential in creating reliable jaw crusher parts capable of meeting the demands of extensive industrial use.

| Part Name | Material | Durability Rating | Performance Impact |

|---|---|---|---|

| Jaw Plate | High Manganese Steel | 9/10 | High wear resistance and impact strength |

| Toggle Plate | Carbon Steel | 8/10 | Provides support and flexibility |

| Pitman | Alloy Steel | 9/10 | Enhanced tensile strength and durability |

| Cheek Plates | High Carbon Steel | 8/10 | Protects the internal structure |

| Mining Screens | Woven Wire Mesh | 7/10 | Optimizes material flow |

| Hydraulic Cylinder | Fabricated Steel | 9/10 | Controls jaw movement |

Maintaining a jaw crusher's efficiency and longevity requires careful attention to its replacement parts. Key components that often need replacement include jaw plates, which are vital for crushing materials effectively. High-quality jaw plates are designed to withstand significant wear and tear, ensuring that they maintain their shape and performance over time. Opting for parts made from durable materials can prevent frequent replacements and minimize downtime in operations.

Another critical aspect of jaw crusher maintenance is the swing and fixed jaw shaft. The shafts must be precisely engineered to handle the immense stress produced during crushing. Regularly inspecting and replacing worn shafts can help prevent catastrophic failures that may lead to costly repairs. Additionally, proper lubrication of these parts is essential for reducing friction and prolonging the life of the machine. By investing in top-quality replacement components, operators can significantly enhance the performance and durability of their jaw crushers, ensuring they operate efficiently in various applications.

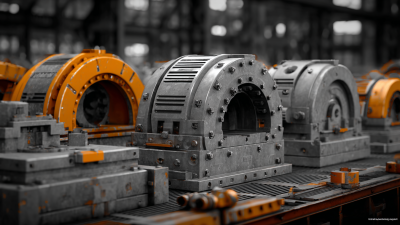

Recent innovations in jaw crusher design have significantly pushed the boundaries of efficiency and performance in the mining and construction industries. Engineers and manufacturers have focused on enhancing key components, such as the crushing chamber and jaw plates, to optimize the material flow and reduce downtime. Redesigned chamber profiles allow for better material engagement, which not only improves the crushing process but also increases the lifespan of the equipment. Advances in finite element analysis have enabled the development of more durable jaw profiles that withstand severe operational stresses.

Furthermore, the integration of technology into jaw crushers is revolutionizing their operation. Modern systems leverage automation and smart monitoring, allowing for real-time performance tracking and predictive maintenance capabilities. This shift to digital solutions helps operators to optimize their processes more efficiently, reducing operational costs and enhancing productivity. Innovations such as hydraulic adjustment systems enable quick changes to the crushing settings, adapting to varying material characteristics without significant delays. These developments exemplify the industry's commitment to improving efficiency while maintaining the robustness and reliability that operators expect from jaw crushers.

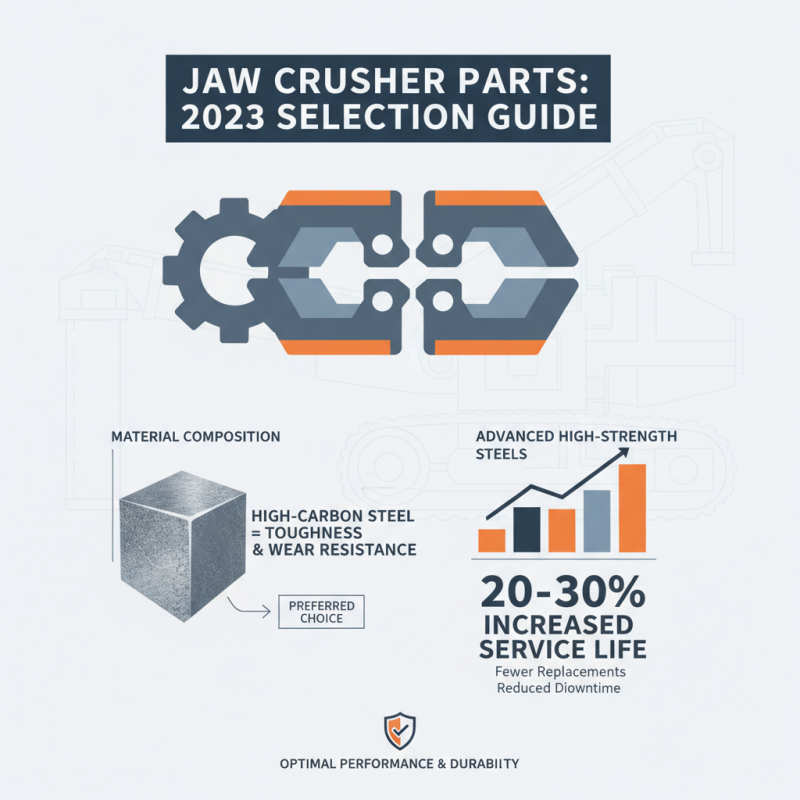

When selecting jaw crusher parts in 2023, several critical factors must be considered to ensure optimal performance and durability. One of the foremost elements is the material composition of the parts. High-carbon steel, for instance, is widely recognized for its toughness and resistance to wear, making it a preferred choice for jaw crusher components. According to a recent industry report by the International Journal of Engineering Research & Technology, the use of advanced high-strength steels can lead to a 20-30% increase in the service life of wear components, resulting in fewer replacements and reduced downtime.

Another essential factor is the fit and compatibility of the parts within the overall system. Poorly fitting components can lead to increased vibration and misalignment issues, which directly affect the operational efficiency of the crusher. The Aggregate Research International notes that approximately 40% of maintenance costs are attributed to improper part selection and installation. Consequently, thorough evaluation of specifications and the potential impact on the crushing process is crucial. Furthermore, embracing innovations such as modular designs can significantly enhance the ease of maintenance and adaptability of the equipment, aligning with ongoing trends in the industry towards increased efficiency and reduced operational costs.