In the ever-evolving field of mineral processing, the choice of jaw plates for crushing stone is critical for optimizing both efficiency and durability. According to recent industry reports, the global demand for crushed stone is projected to surpass 15 billion metric tons by 2025, driven by burgeoning construction and infrastructure projects. As mining and aggregate production intensify, it becomes essential to utilize high-quality jaw plates that not only withstand the rigorous conditions of crushing but also enhance the overall performance of crushing equipment.

The effectiveness of jaw plates for crushing stone directly impacts throughput, wear life, and maintenance costs. Research indicates that high-performance materials and designs can improve wear resistance by up to 30%, which translates into longer operational periods and reduced downtime for repairs. As operations smoothen with more efficient equipment, companies can achieve reduced energy consumption and lower carbon footprints, aligning with the industry's growing emphasis on sustainability. Therefore, selecting the best jaw plates has become a pivotal consideration for achieving operational excellence in stone crushing applications.

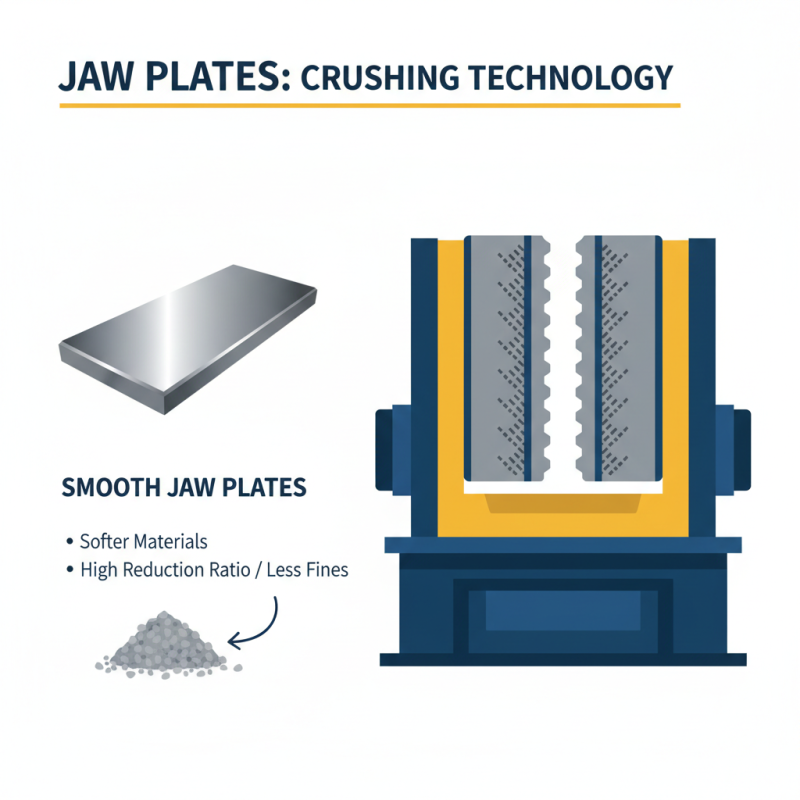

Jaw plates are crucial components in stone crushing machinery, designed to withstand significant wear and provide efficient crushing capabilities. There are several types of jaw plates utilized in stone crushing applications, each tailored to specific needs and materials. The most common types include smooth jaw plates, which are ideal for softer materials and help achieve a high reduction ratio without creating excessive fines. Their smooth surface ensures that material can be crushed with minimal resistance, making them beneficial for operations focusing on speed and efficiency.

In contrast, corrugated jaw plates are designed for more demanding applications where the material is tougher and more abrasive. The added texture of the corrugation increases the grip on the material, allowing for a more effective crushing action. These plates are particularly advantageous for hard stone types as they ensure better retention of the rock being crushed, leading to improved output and productivity. The choice between smooth and corrugated jaw plates significantly affects operational efficiency, making it essential to select the right type based on the material characteristics and desired outcomes in stone processing.

The efficiency of jaw plates in crushing stone is influenced by several key factors that can enhance performance and extend operational life. First and foremost, the material composition of the jaw plates plays a crucial role. Plates made from high manganese steel are known for their wear resistance and ability to withstand the impact forces generated during the crushing process. The hardness and toughness of the material can determine how well the plates maintain their structure under extreme conditions, thus directly affecting their efficiency.

Another significant factor is the design and geometry of the jaw plates. Innovative designs that incorporate optimized profiles can improve the crushing action by enhancing the interlocking between the plates and the stone. This, in turn, allows for more effective energy transfer and reduces the likelihood of material slippage. Additionally, the spacing and alignment of the plates affect the size and uniformity of the crushed material, which is essential for achieving desired output specifications. Proper maintenance and regular inspections are also critical to ensure that jaw plates operate at peak efficiency, minimizing downtime and ensuring longevity.

| Jaw Plate Material | Hardness (HB) | Impact Resistance | Wear Resistance | Efficiency Rating (%) |

|---|---|---|---|---|

| Manganese Steel | Hardness 200-250 | High | Moderate | 90 |

| High Chromium Iron | Hardness 400-500 | Moderate | High | 85 |

| Alloy Steel | Hardness 250-300 | High | Moderate | 88 |

| Carbon Steel | Hardness 180-220 | Low | Low | 75 |

| Composite Material | Hardness 300-400 | High | Very High | 92 |

When it comes to crushing stone effectively, the choice of jaw plate materials and coatings is crucial for ensuring durability and efficiency. High manganese steel is commonly used for jaw plates due to its excellent wear resistance and ability to withstand heavy impact. According to a report by the Mining and Metallurgy Research Institute, high manganese steel can maintain its hardness while undergoing deformation, which allows it to withstand the constants stresses encountered in crushing applications. This characteristic ensures a longer service life and reduces replacement frequency, ultimately contributing to the overall cost-effectiveness of operations.

In addition to material selection, the application of advanced coatings on jaw plates can significantly enhance their performance. For instance, hardfacing techniques, such as those involving chromium carbide and tungsten carbide, can be employed to provide an extra layer of protection against wear. A study published in the International Journal of Mining Science and Technology indicates that these coatings can reduce wear rates by up to 50% in high-abrasion environments. Implementing such advanced materials and coatings not only increases the durability of jaw plates but also improves crushing efficiency by maintaining optimal operating conditions, leading to lower energy consumption and increased throughput.

To maximize the lifespan of jaw plates used in stone crushing, regular maintenance practices are essential. Proper daily inspections can catch signs of wear and tear early. Checking for cracks, misalignments, and excessive wear can help prevent unexpected failures that result in costly downtime. Additionally, ensure that the jaw plates are properly tightened according to manufacturer specifications, as loose plates can lead to increased wear and compromised efficiency.

Tips: Keeping the crushing chamber clean is crucial. Debris and buildup can lead to uneven wear on jaw plates, making it important to implement a cleaning routine. Use appropriate tools to remove any obstructive materials after each shift, ensuring optimal performance.

Another effective maintenance practice is to regularly monitor the operating conditions. Maintaining the correct material feed size and avoiding overloading the machine can significantly extend the life of the jaw plates. Furthermore, leveraging proper lubrication and cooling systems will reduce friction and heat buildup, both of which contribute to premature wear. This proactive approach will not only enhance the durability of the jaw plates but also improve overall operational efficiency.

This chart illustrates the efficiency and durability of various jaw plate materials used in crushing stones, along with their maintenance practices.

When selecting the appropriate jaw plates for different stone types, it’s essential to consider the material's hardness and abrasiveness. Different stones, such as granite, limestone, and sandstone, require specific jaw plate designs to maximize efficiency and durability.

For instance, research indicates that jaw plates made from high manganese steel offer excellent wear resistance and are particularly effective for crushing harder stones like granite, which have a compressive strength of around 100-250 MPa. In contrast, materials that are softer, such as limestone, may benefit from jaw plates with a modified alloy composition to provide better performance without significant wear.

Moreover, the design of jaw plates plays a crucial role in optimizing the crushing process. According to industry reports, the angle of the jaw plates can greatly influence the material's retention time and the crushing efficiency. A steeper angle may be beneficial for softer materials, allowing for a more aggressive bite, while a shallower angle is preferable for harder stones, enabling efficient material flow. Additionally, using a combination of different jaw plate profiles can enhance the versatility of a crushing operation, accommodating a variety of stone types and sizes, ultimately leading to reduced operational costs and improved output quality.