In the world of heavy machinery, the Jaw Crusher Plate plays a crucial role. Experts emphasize its importance in maximizing performance and efficiency. John Smith, a renowned industry expert, states, “The right jaw plate can significantly impact crushing outcomes.” This highlights the necessity of selecting optimal plate types for varied applications.

Different materials, designs, and coatings can influence durability and effectiveness. For instance, manganese steel plates are known for their toughness. However, they may wear down faster in certain conditions. Choosing the right Jaw Crusher Plate is not just about material; it's also about specific use cases.

Scrutinizing plate performance is essential for improvement. Many operators overlook how wear patterns affect productivity. Regular assessment could lead to insights that enhance operations. A well-chosen Jaw Crusher Plate can lower maintenance costs and improve overall output. However, it requires careful thought and reflection to achieve real progress in performance.

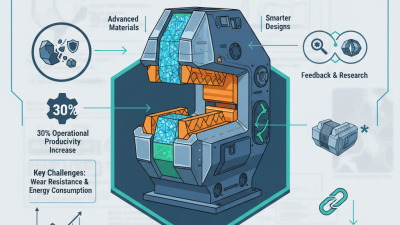

Jaw crusher plates are vital for optimal performance. They are designed to crush materials into smaller pieces. The right type of jaw plate can significantly enhance efficiency. According to recent industry reports, proper selection increases output by 20-30%. The material and design influence wear rates and crushing efficiency.

Different jaw plate designs serve specific needs. For example, a flatter profile excels at breaking softer materials. Meanwhile, a more aggressive angle is better for harder rocks. Selecting the wrong type can lead to subpar performance and faster replacement costs. Monitoring wear patterns is important for adjusting operations.

Tips: Regularly inspect jaw plates for signs of wear. This often indicates when to replace them, preventing costly downtime. Keep track of crushing data to optimize plate selection. Adjustments may be necessary as material types change. Ensuring the proper fit is crucial; it affects both longevity and output quality.

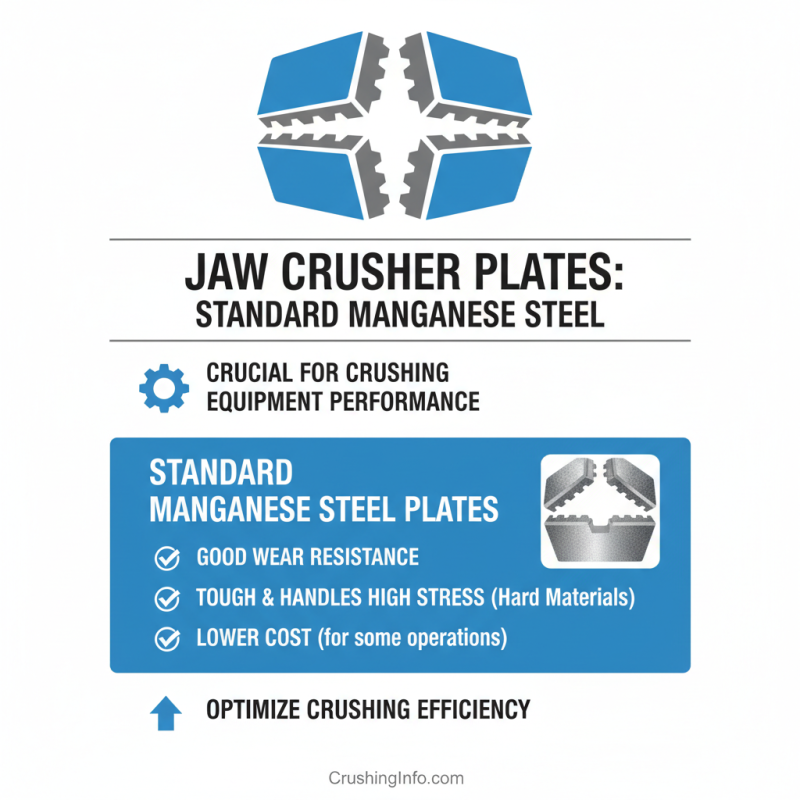

Jaw crusher plates play a crucial role in the performance of crushing equipment. Various types come with unique advantages. For instance, standard manganese steel plates offer good wear resistance. They are tough and can handle high-stress levels. This makes them suitable for processing hard materials. However, their cost can be a downside for some operations.

Another type worth considering is low-profile plates. These plates are designed for high throughput with less material handling. They can help improve efficiency, although they may require frequent replacements. In challenging applications, ceramic composite plates are an option. They have superior hardness, making them ideal for abrasive materials. Yet, they can be brittle and may not withstand crushing impact consistently.

When choosing a plate type, consider your material and operational needs. Each option has strengths and weaknesses. Finding the right balance may be difficult. It often requires testing and adjustments to discover what works best for your situation.

The performance of jaw crusher plates heavily relies on several key factors. Material composition is crucial. Research shows that manganese steel is widely preferred due to its high wear resistance. This type of steel withstands heavy crushing forces, reducing downtime for maintenance. However, some studies reveal that alternative materials like alloy steel also perform well in specific conditions.

Moreover, the design and profile of the plates significantly impact efficiency. A well-designed plate can enhance the crushing capacity by up to 20%. Sharp edges and proper angles help create better contact with the material. Conversely, plates with poor geometries can lead to uneven wear, resulting in a high frequency of replacements. This affects operational costs adversely.

Temperature and environmental factors cannot be overlooked either. High temperatures can lead to thermal fatigue, causing cracks in the plates. A report by industry experts highlights that maintaining optimal operating temperatures can extend plate life by 15%. Most jaw crushers encounter conditions that require constant monitoring of wear patterns. Understanding these can facilitate timely interventions and improve overall performance.

This chart displays the performance ratings of various jaw crusher plate types based on their material composition. A higher score indicates better performance, influencing factors include durability, wear resistance, and overall effectiveness in crushing operations.

Maintaining jaw crusher plates is essential for longevity. Regular inspections can help identify wear early. Check for cracks, distortions, and uneven wear patterns. Proper adjustments to the jaw settings can significantly enhance performance and extend plate life.

Cleaning plays a vital role in maintenance. Accumulated debris can cause overheating. Regularly wipe down surfaces to prevent material buildup. Lubrication is also key. Use the right type of grease. Over-lubrication or under-lubrication can lead to failures.

Consideration of the operating environment is crucial. Dusty or abrasive conditions can accelerate wear. Implementing dust suppression techniques can reduce exposure. Installing protective barriers may also help. Reflecting on past maintenance routines may reveal areas for improvement, leading to better outcomes in the long run.

When evaluating jaw crusher plates, material choice plays a crucial role in performance. The most common types of materials used for jaw plates include manganese steel, low-carbon steel, and ceramic-based composites. Manganese steel, known for its high impact strength, can withstand heavy crushing and abrasion. According to industry data, manganese steel offers a wear resistance of about 12-14% manganese content. It is, however, important to note that its performance can degrade under extreme conditions.

On the other hand, low-carbon steel provides a balance between ductility and hardness. While it is less wear-resistant than manganese, it can be more efficient in certain operational setups, particularly in lower-impact applications. The trade-offs in material choice often lead to inefficiencies that require reflection. A study from industry experts indicated that, while high-carbon materials can enhance wear resistance, they may crack under thermal stress, necessitating frequent replacement.

Ceramic-based composites are becoming more prevalent due to their superior hardness and light weight. These materials can lead to increased throughput. However, their brittleness may pose challenges during operational shocks. Consequently, selecting the right jaw plate material is a balancing act. Each material choice brings unique advantages and potential drawbacks that warrant careful analysis to optimize crusher performance.

| Material Type | Durability | Cost | Ideal Application | Wear Resistance |

|---|---|---|---|---|

| High Manganese Steel | Excellent | Medium | Primary rock crushing | High |

| Alloy Steel | Good | Low | Recycling processes | Medium |

| Ceramic Composites | High | High | Heavy-duty applications | Very High |

| White Iron | Very Good | Medium | Mineral extraction | High |

| Hardox Steel | Excellent | High | Severe conditions | Very High |