In the world of mining and aggregate production, the efficiency and performance of a cone crusher are heavily dependent on the quality of its components. Among these components, the *Cone Crusher Liner* plays a pivotal role in ensuring optimal performance. The *Cone Crusher Liner* not only directly impacts the crushing capabilities but also affects the wear life of the machine, making it a critical element to consider for any operation looking to maximize productivity and reduce downtime.

As we delve into the top ten *Cone Crusher Liners* for 2023, it is essential to analyze the features that contribute to their effectiveness. This includes factors such as material composition, design, and wear resistance, all of which are crucial for achieving the desired output and maintaining the machine's longevity. Choosing the right *Cone Crusher Liner* can significantly improve the overall performance of your crushing equipment, ensuring that it operates at peak efficiency while minimizing operational costs.

In this guide, we will explore the best options available in the market, focusing on their unique attributes and how they can enhance the functionality of cone crushers across various applications. Whether you are in the mining industry or involved in recycling processes, understanding the significance of *Cone Crusher Liners* will empower you to make informed decisions that lead to improved operational success in 2023.

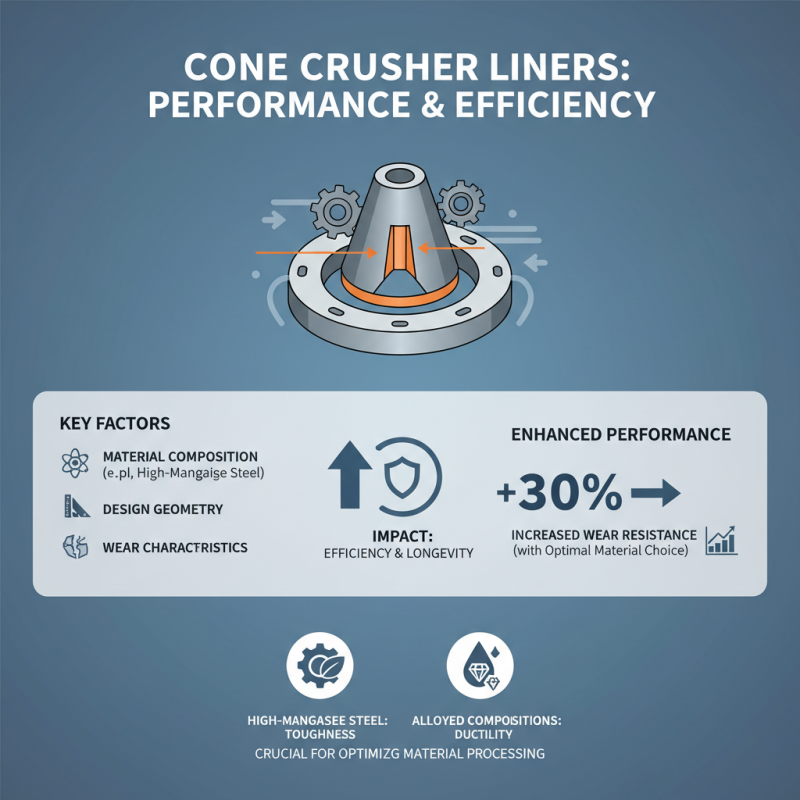

Cone crusher liners play a critical role in the efficiency and effectiveness of crushing operations in various industries, particularly in mining and aggregate production. These liners are designed to withstand significant wear and tear, making them essential components in extending the life of a cone crusher. According to a report by the International Journal of Engineering Research and Applications, the proper selection and maintenance of cone crusher liners can improve the overall productivity of crushing systems by up to 30%. This highlights the importance of not only choosing high-quality liners but also ensuring they are suited to specific operating conditions.

Moreover, the wear characteristics of cone crusher liners are pivotal in achieving optimal performance. A study published in the Journal of Materials Processing Technology indicates that the right liner profile can lead to a reduction in operational costs, offering savings of nearly 20-25% in replacement and upkeep expenses. As mining and aggregate operations become more competitive, understanding the nuances of cone crusher liners, including their material composition and wear patterns, is essential for companies seeking to maximize output and minimize downtime. Thus, investing in research and development related to these liners is crucial for future advancements in crushing technology.

When it comes to ensuring optimal performance in cone crushers, the choice of liner materials plays a crucial role. Cone crusher liners are primarily made from different types of metal alloys, designed to provide the necessary hardness and resistance to wear during crushing operations. Commonly used materials include high manganese steel, which offers great impact strength and adaptability, making it ideal for a variety of hard rock applications. Its ability to work-harden means that as it endures impact, its surface becomes tougher, providing extended life and reliability.

Another material that has gained traction is chrome-moly steel, which combines excellent wear resistance with toughness. This alloy is particularly valuable in applications requiring significant abrasion resistance while still being able to withstand impacts. Innovations in materials technology have led to the development of hybrid liners that blend the properties of various materials, enhancing performance in specific applications by maximizing wear life while improving throughput efficiency. Understanding the different material types used in cone crusher liners not only helps in selecting the right option but also in optimizing overall equipment performance in diverse operational conditions.

| Material Type | Hardness (HRC) | Weight (kg) | Lifespan (Hours) | Cost ($) |

|---|---|---|---|---|

| High Manganese Steel | 12-14 | 350 | 800 | 150 |

| Alloy Steel | 30-34 | 300 | 1000 | 175 |

| Chrome-Moly Steel | 28-32 | 280 | 900 | 160 |

| Martensitic Steel | 45-50 | 320 | 1200 | 200 |

| Ceramic Composite | 40-45 | 250 | 1500 | 300 |

The performance of cone crusher liners is crucial for optimizing material processing in various industries. Features such as material composition, design geometry, and wear characteristics significantly impact a cone crusher's efficiency and longevity. According to industry reports, the choice of liner material can enhance wear resistance by up to 30% compared to standard options. High manganese steel and alloyed compositions are frequently utilized, providing a balance between toughness and ductility, essential for handling materials of varying hardness.

Performance metrics, such as throughput, reduction ratio, and power consumption, play a pivotal role in assessing the effectiveness of cone crusher liners. The optimal design can increase throughput by approximately 20%, allowing for more efficient crushing operations. Additionally, advances in liner profile technology, specifically tailored for different applications, can improve the reduction ratio by 15%, ensuring the required particle size consistency is maintained. As industries continue to seek efficiency and cost-effectiveness, understanding these features and metrics will be critical for selecting the best cone crusher liners in 2023.

In 2023, the performance of cone crushers is significantly influenced by the quality of their liners. A comparative analysis of various cone crusher liner brands reveals that the materials used and the design of the liners play a crucial role in enhancing operational efficiency and lifespan. Liners constructed from high-quality manganese steel typically offer superior wear resistance, which is essential in maximizing productivity in challenging crushing environments. Furthermore, liners with optimized geometries contribute to better material flow and reduced downtime, ultimately leading to cost savings over time.

Additionally, the incorporation of innovative technologies in liner production has led to the emergence of custom solutions tailored to specific crushing applications. Different materials, such as alloy steels and ceramic compounds, are increasingly being utilized to improve impact resistance and extend the service life of liners. The durability and performance of cone crusher liners are critical in maintaining the overall efficiency of mining and aggregate operations, making the choice of liner an essential consideration for businesses aiming to achieve optimal performance in their production processes.

Maintaining cone crusher liners is crucial for maximizing their lifespan and ensuring optimal performance in various applications. One of the key maintenance practices involves regular inspection of the liners for signs of wear and damage. By closely monitoring the condition of the liners, operators can identify issues early, preventing further complications that could lead to more significant downtime or costly repairs. It’s essential to document wear patterns and analyze them to make informed decisions regarding when to replace or refurbish the liners.

Another vital aspect of maintenance is ensuring proper lubrication of the cone crusher. Lubrication reduces friction and heat generation, which can significantly extend the life of the liners. Operators should follow manufacturer recommendations on lubricant type and intervals to ensure the most effective protection. Furthermore, maintaining clean oil is imperative; contaminants in the lubricant can lead to increased wear and tear on the liners. Implementing a regular maintenance schedule that incorporates these practices will not only enhance the lifespan of the cone crusher liners but also contribute to the overall efficiency and productivity of crushing operations.