The moving jaw mechanism has long been a staple in various industries, particularly in manufacturing and engineering. As we approach 2025, the landscape of innovations surrounding the moving jaw is set to transform dramatically. Industry experts, like Dr. Emily Carson, a leading authority in mechanical engineering, emphasize the importance of these advancements, stating, "The evolution of moving jaw technology is not just about improved efficiency; it’s about redefining the standard of precision in our industry."

In this rapidly advancing field, the integration of digital technologies with traditional moving jaw designs is paving the way for unprecedented capabilities. From enhanced automation to smart materials, the innovations on the horizon are reshaping how we understand motion and function. As organizations strive for greater productivity and sustainability, these top ten moving jaw innovations are set to revolutionize production processes, significantly impacting sectors ranging from automotive to robotics.

In the following sections, we will explore the leading innovations of 2025 that are poised to change the dynamics of the moving jaw industry. By delving into these groundbreaking developments, we aim to provide insights into how businesses can leverage these advancements to stay competitive and meet the growing demands of their markets.

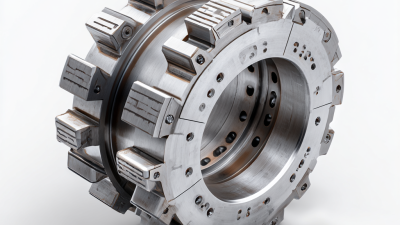

The moving jaw in machinery plays a pivotal role in various industries, especially in the realms of manufacturing and material processing. Recent innovations focus on integrating smart technologies to enhance the efficiency and precision of moving jaw operations. By employing advanced sensors and IoT connectivity, these systems can now monitor real-time performance data, enabling predictive maintenance and reducing downtime. This shift not only streamlines the operational workflow but also significantly cuts costs associated with unexpected failures.

Moreover, the incorporation of artificial intelligence algorithms into moving jaw designs allows for adaptive performance adjustments based on real-time conditions and workloads. These smart technologies facilitate seamless coordination between mechanical components, ensuring optimal performance and energy efficiency. As a result, industries utilizing moving jaw mechanisms can experience heightened productivity and reduced environmental impact, revolutionizing operations and setting new standards for efficiency in manufacturing processes.

In 2025, the integration of AI and machine learning technologies into the moving jaw equipment sector stands to significantly enhance predictive maintenance capabilities. By utilizing real-time data analysis, these technologies can identify potential faults before they become critical issues, allowing for timely interventions. This predictive approach not only minimizes downtime but also extends the lifespan of the equipment, ensuring that operations remain efficient and cost-effective.

The implications of AI-driven predictive maintenance are profound. It enables manufacturers to transition from reactive to proactive maintenance strategies, facilitating smoother operations across the supply chain. As organizations increasingly embrace this technology, they discover that AI can provide insights that were previously unattainable.

However, it is crucial to acknowledge that while AI systems excel in data analysis and pattern recognition, they still require human oversight to interpret complex scenarios and make strategic decisions. As this field evolves, the collaboration between AI and human expertise will play a pivotal role in shaping the future of the moving jaw industry.

The moving jaw mechanism in various industrial applications plays a crucial role in machinery operation, but it has often been linked to safety hazards. Recent innovations in moving jaw design aim to significantly enhance safety standards in the workplace. According to a report by the International Labor Organization (ILO), workplace accidents involving machinery account for approximately 17% of all occupational injuries worldwide. Innovative designs that incorporate features such as improved jaw locking mechanisms and enhanced shielding are vital in mitigating these risks.

One notable advancement is the integration of smart technology into moving jaws. Systems equipped with sensors can detect abnormal operating conditions and automatically shut down machinery to prevent accidents. A study published in the Journal of Safety Research highlighted that workplaces that adopted these smart technologies saw a 30% reduction in machinery-related accidents over five years. Additionally, materials used in modern moving jaw designs have shifted towards high-strength composites, which not only improve durability but also reduce the weight of the moving components, contributing to overall safer operation.

These technologies underscore the industry’s commitment to enhancing safety. By focusing on innovative moving jaw designs, companies can not only comply with stringent safety regulations but also foster a work environment that prioritizes employee well-being. Investing in these innovations is not just a financial decision; it's a crucial step towards a safer, more efficient future in manufacturing.

This chart illustrates the top 10 innovations in moving jaw design that enhance safety standards and reduce workplace accidents. The data represents the estimated percentage reduction in accidents due to the implementation of these innovations.

The manufacturing of moving jaw components is experiencing a transformative shift as sustainability trends gain prominence in the industry. Eco-friendly materials are becoming increasingly integrated into the production processes, reflecting a broader commitment to environmental responsibility. Innovations such as biodegradable composites and recycled metals are not only reducing the ecological footprint but also enhancing the performance characteristics of these components. By embracing sustainable alternatives, manufacturers can minimize waste and contribute to a circular economy, aligning with the global push for greener manufacturing practices.

Moreover, the use of eco-friendly materials is promoting advancements in product design and functionality. Manufacturers are exploring lightweight materials that maintain strength and durability while also being environmentally benign. This shift is crucial, as it enables the creation of moving jaw components that meet the rigorous demands of modern machinery while adhering to sustainability standards. By prioritizing eco-friendly materials, the industry is paving the way for future innovations that not only improve operational efficiency but also foster a healthier planet.

| Innovation | Material Type | Sustainability Rating | Impact on Production |

|---|---|---|---|

| Bio-Based Polymers | Natural Fibers | A+ | Reduces waste and energy usage |

| Aluminum Alloys | Recycled Metals | A | Lightweight and strong, lower emissions |

| 3D Printing Technology | PLA Filaments | A- | Minimizes material waste |

| Hybrid Composites | Bamboo & Resins | B+ | Durable and renewable |

| Recycled Plastics | Post-Consumer Waste | B | Conserves resources and reduces landfill waste |

| Organic Coatings | Bio-Based Paints | A+ | Safer for workers and environment |

| Smart Manufacturing | IoT-Enabled Devices | A | Improves efficiency and reduces resources |

| Electric Drive Systems | Low Carbon Materials | B+ | Reduces greenhouse gas emissions |

| Carbon Fiber Reinforcement | Bio-Derived Carbon Fibers | A- | Lightweight, strong, less energy in transport |

| Circular Economy Practices | Upcycled Components | A+ | Promotes reuse and reduction of waste |

The moving jaw sector is undergoing a profound transformation, largely driven by the Internet of Things (IoT) and data-driven decision-making strategies. By integrating IoT devices into operational processes, companies can gather real-time data that offers deeper insights into equipment performance and operational efficiency. This connectivity allows businesses to monitor moving jaw machinery continuously, leading to predictive maintenance that minimizes downtime and optimizes resource allocation.

Moreover, the analysis of collected data empowers organizations to make informed, strategic decisions. Advanced algorithms can identify patterns and trends that would be invisible to human operators, enabling businesses to streamline their operations effectively. With data at their fingertips, industry leaders can enhance productivity, reduce costs, and improve overall performance. As IoT technology continues to evolve, its impact on the moving jaw sector will likely grow, fostering innovations that enhance both operational capabilities and customer satisfaction.